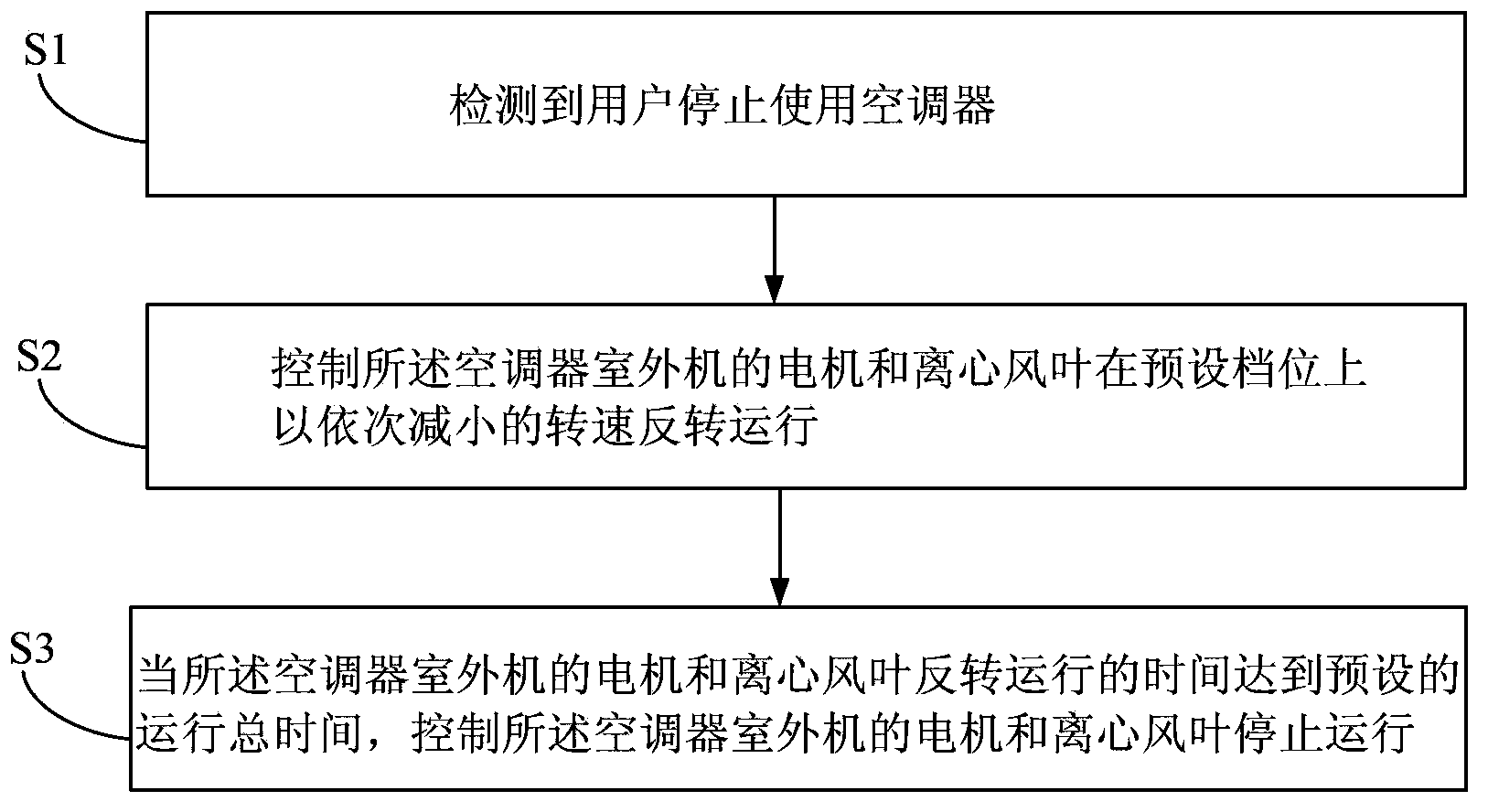

Dust removing control method for heat exchanger of outdoor unit of air-cooled air conditioner

A technology for an air conditioner room and a control method, which is applied to heating and ventilation control systems, household heating, heating methods, etc., can solve problems such as the life of system components or the unsatisfactory dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Assume that the outdoor unit heat exchanger dust removal main control board of the air-cooled air conditioner has four gears for the reverse speed of the motor and centrifugal fan blades of the outdoor unit, and see Table (1) for the reverse speed of each gear. And the running time of each reverse speed is 60 seconds.

[0026] Table (1): The speed table of each gear in the reverse operation of the outdoor fan

[0027] reverse gear

[0028] When the user stops using the air conditioner, the main control board detects this signal, and the motor and the centrifugal fan of the outdoor unit of the air-cooled air conditioner are controlled by the main control board, and run in reverse at the highest speed V1 of 850RPM for 60 seconds, and then Switch to the higher speed V2 and run reversely at 700RPM for 60 seconds, then continue to switch to the third speed V3 and run reversely at 550RPM for 60 seconds, and finally run reversely at the lowest speed V4 at 400RPM for ...

example 2

[0030] Assume that the outdoor unit heat exchanger dust removal main control board of the air-cooled air conditioner has three gears for the reverse running speed of the motor and centrifugal fan blades of the outdoor unit, and the reverse running speed for each gear is shown in Table (2). The running time corresponding to each reverse rotation speed is different, which are 120 seconds, 90 seconds and 60 seconds respectively.

[0031] Table (2): Reverse running tachometer for each gear of the outdoor motor

[0032] reverse gear

V 1

V 2

V 3

Reverse running speed (RPM, revolutions per minute)

800

700

600

[0033] Corresponding running time (seconds)

120

90

60

[0034] When the user stops using the air conditioner, the main control board detects this signal, and the motor and centrifugal fan of the outdoor unit of the air-cooled air conditioner will run in reverse at the highest speed V1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com