Multipurpose semicontinuous vacuum induction casting furnace

A vacuum induction, semi-continuous technology, applied in the direction of furnaces, crucible furnaces, furnace types, etc., can solve the problems of no function expansion interface, inability to adapt to the market demand for product diversification, and inability to perform secondary purification of molten metal, etc., to achieve improved Effects of metal quality, reduced pump-down time, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

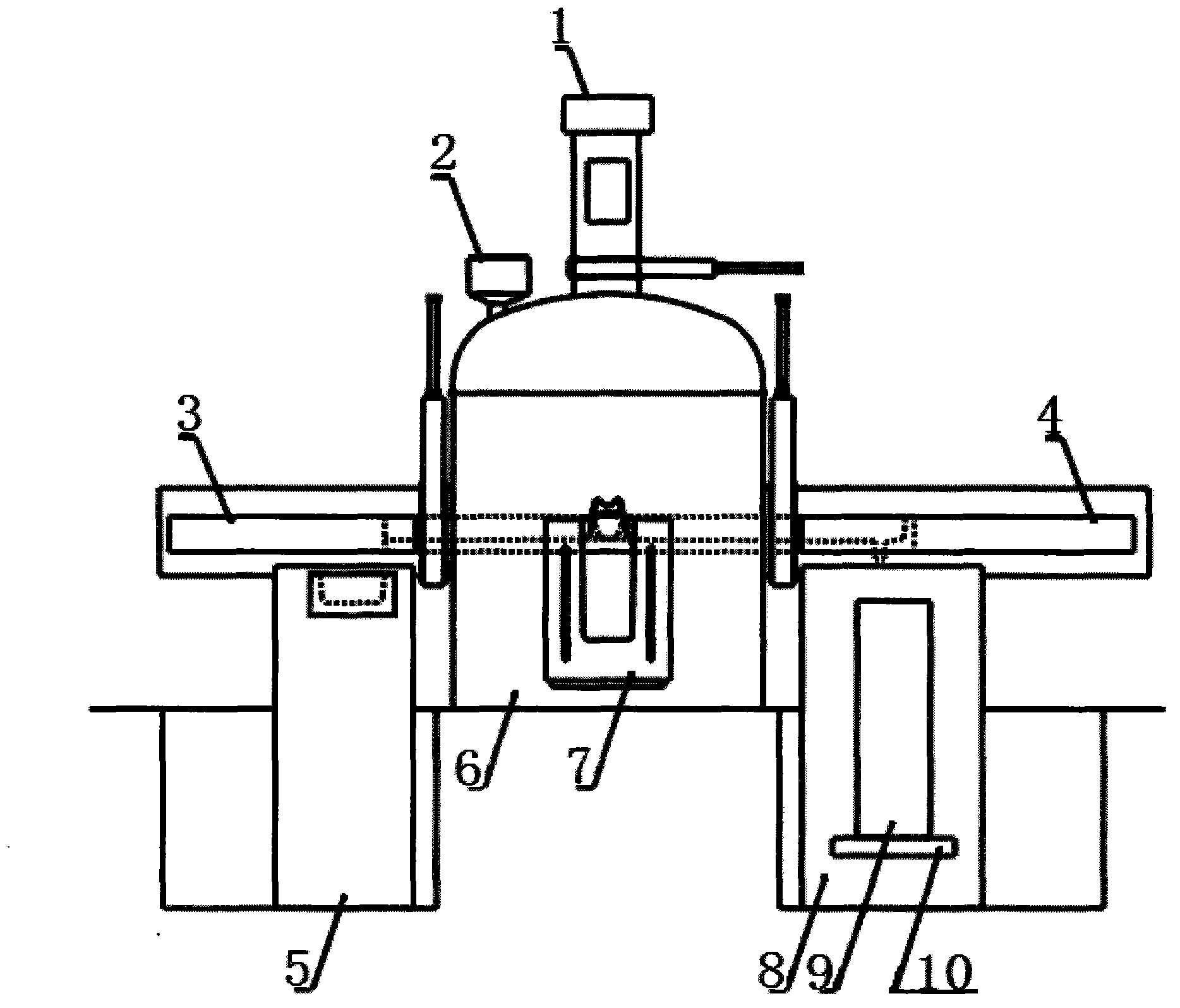

[0015] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] See figure 1 , a multi-purpose semi-continuous vacuum induction melting furnace, including a melting chamber 6, the upper part of the melting chamber 6 is provided with a continuous feeding device 1 and an alloy feeding port 2, after the molten metal is melted, the alloy feeding 2 can be passed according to the composition of the molten metal For alloy addition, the melting chamber 6 is provided with an induction heating crucible device 7, the continuous feeding device 1 is arranged directly above the induction heating crucible device 7, the induction heating crucible device 7 is provided with a liquid outlet 11, and the outlet of the induction heating crucible device 7 is A chute is arranged on the side of the liquid port 11, a casting chamber is arranged below the chute, an ingot mold is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com