Dead load type torque standardizing machine

A deadweight, standard machine technology, applied in the direction of force/torque/power measuring instrument calibration/testing, instruments, measuring devices, etc., can solve problems such as low efficiency, inability to accurately and quickly verify, poor reliability, etc., and achieve expanded detection Range, solve the effect of accurate automatic arbitrary loading, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

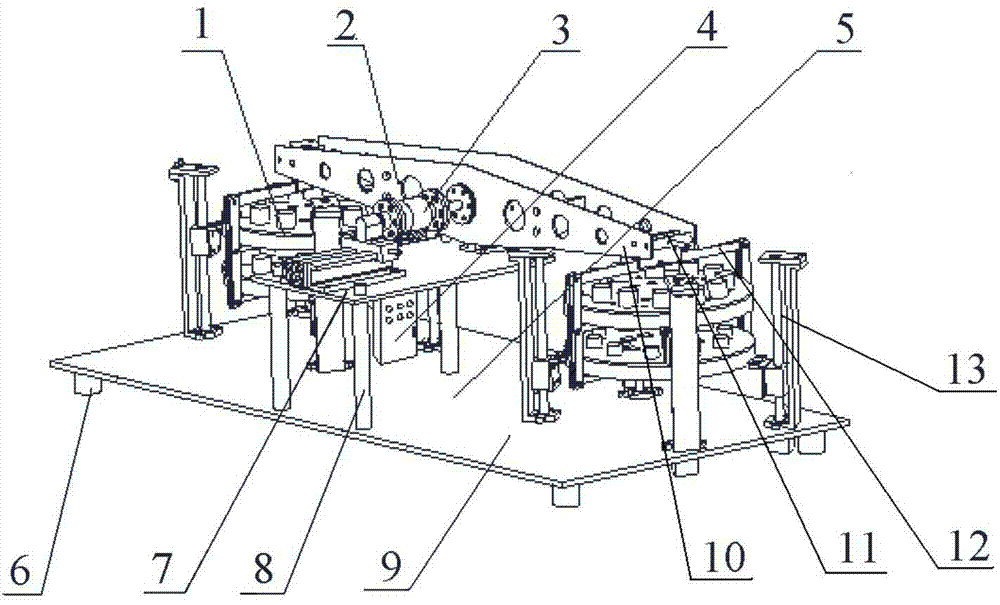

[0030] See attached figure 1 , attached figure 2 And attached image 3 , the static weight type torque standard machine of the present invention comprises a support member 5, a standard force loading mechanism 1, a lever mechanism 2, a torque sensor installation part 3 and a control system 4 thereof;

[0031] The supporting part 5 includes a base plate 9, four uprights 8 and a mounting plate 7, the mounting plate 7 is fixed on the base plate 9 through the uprights 8, the bottom of the base plate 9 is in contact with the ground through the leveling feet 6, and the base plate 9 and the mounting plate 7 are installed horizontally; the main function is to carry the weight of the complete machine and provide support for installing the detected torque sensor 19.

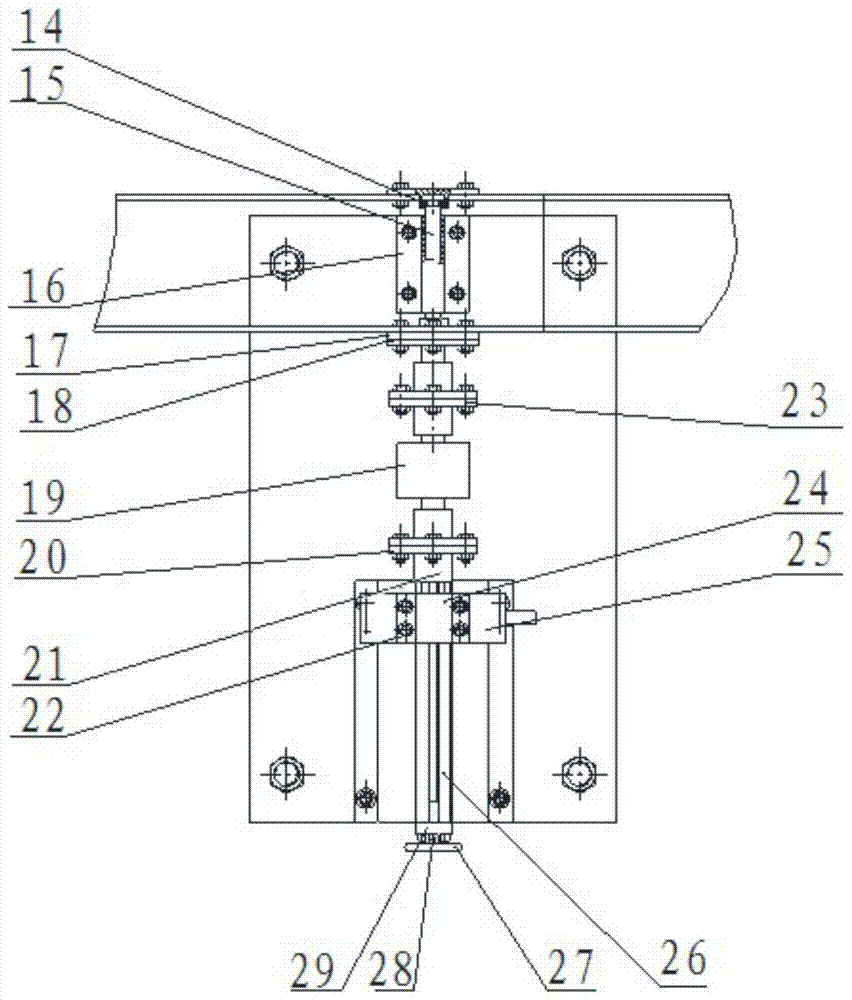

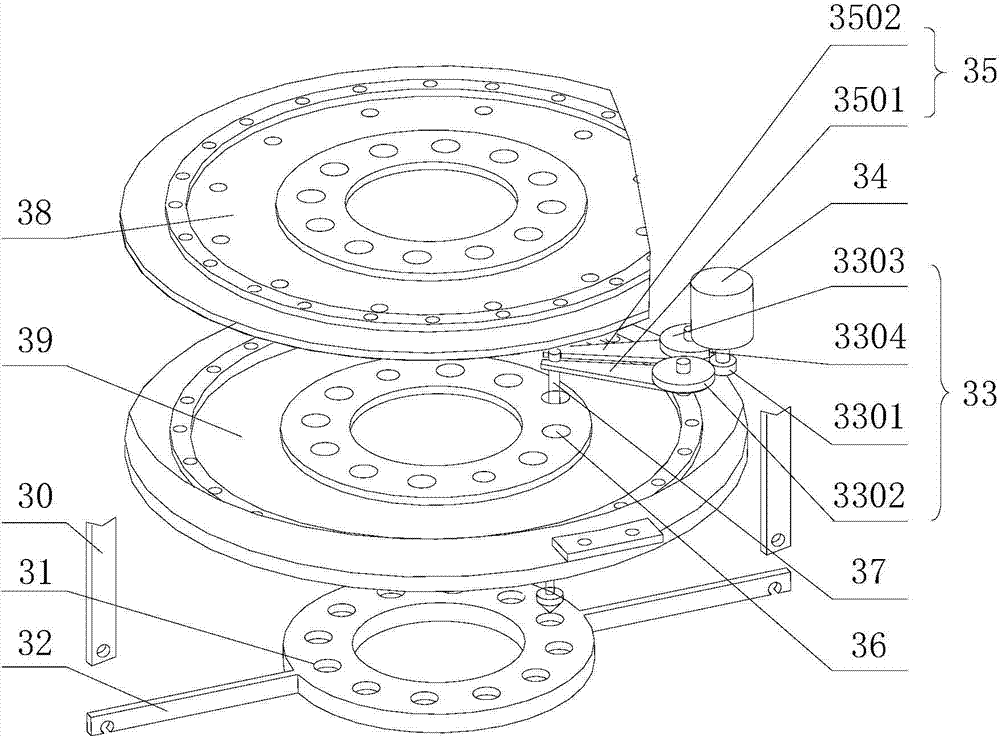

[0032] The lever mechanism 2 includes a force arm 10, a lever leveling mechanism, a hinged part 11 and a fixed output shaft 18. The force arm 10 is a symmetrical structure, and a fixed output shaft 18 is arranged in the...

Embodiment 2

[0047] As a deadweight torque standard machine with a model of 10Nm, the standard machine is a verification device in which the torque generated by the standard weight is added to the torque sensor 19 under test. It consists of a supporting part 5, a standard force loading mechanism 1, a lever mechanism 2, a torque sensor installation part 3 and its control system 4.

[0048] The measurement range of this device is 0.1-10Nm. After analysis, it can be known that the trays of the weight loading mechanism on both sides can be divided into two layers. Each weight in the small weight carrying plate of the first layer generates a torque of 0.1Nm. Each weight in the multilayer weight bearing plate generates a torque of 1Nm, and can generate all torques from 0.1 to 10Nm by superposition.

[0049] The length of the force arm 10 of the device is 500mm. To generate a torque of 0.1Nm, a weight of 20g is required. To generate a torque of 1Nm, a weight of 200g is selected. However, because ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com