Cement powder silo dust removal and swiping soot blowing automatic control system

An automatic control, cement powder technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of tedious installation and debugging, non-periodic equipment, inspection, etc., to achieve less difficulty in installation and debugging, avoid material loading Errors, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

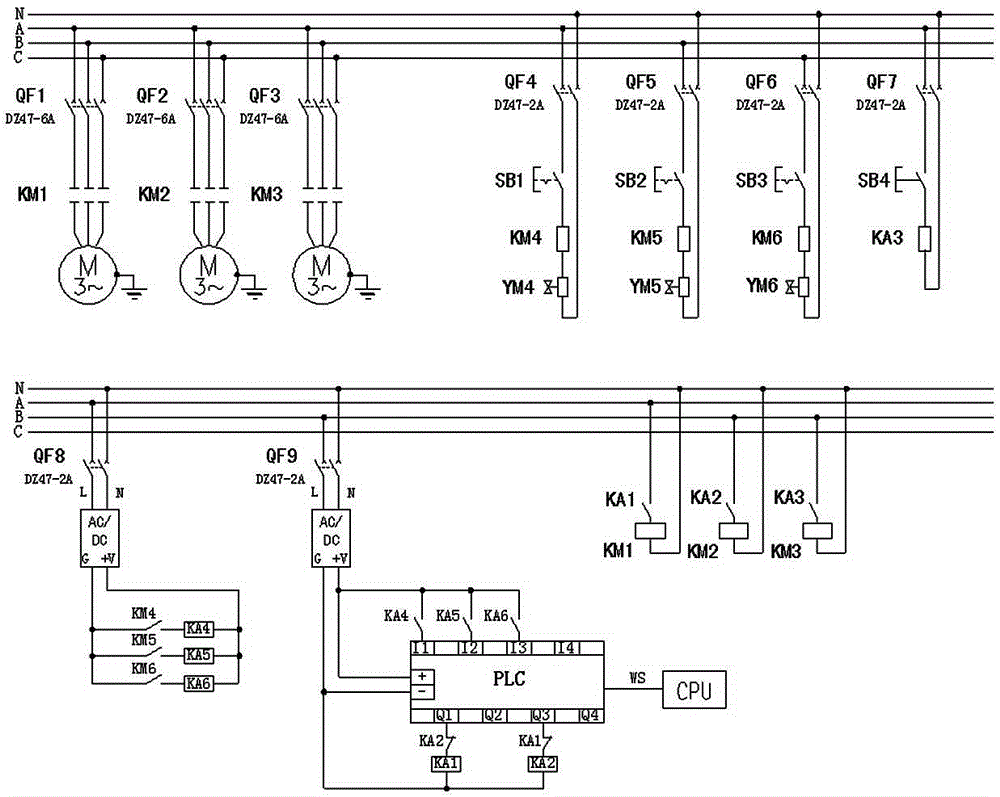

[0008] Concrete structure of the present invention and operating principle are as follows: see figure 1 , mainly including the master switch, controller, executive mechanism and upper PC in the way of plug-in card power-taking; Card power switch, etc. This switch is commonly used in hotel rooms. When the guest enters the room, insert the room card into the special card power switch, and then use the lighting, air conditioning and TV in the room, and then pull it out after leaving. The room card can turn off (delay) the above-mentioned electrical equipment. The master switch is respectively installed at the front end of the corresponding feeding electromagnetic flap, and each master switch is connected in series with the corresponding first relay and the electromagnetic flap control coil through the air switch and the power line, and the first relay The normally open contact of the intermediate relay is connected in series with the coil of the corresponding intermediate relay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com