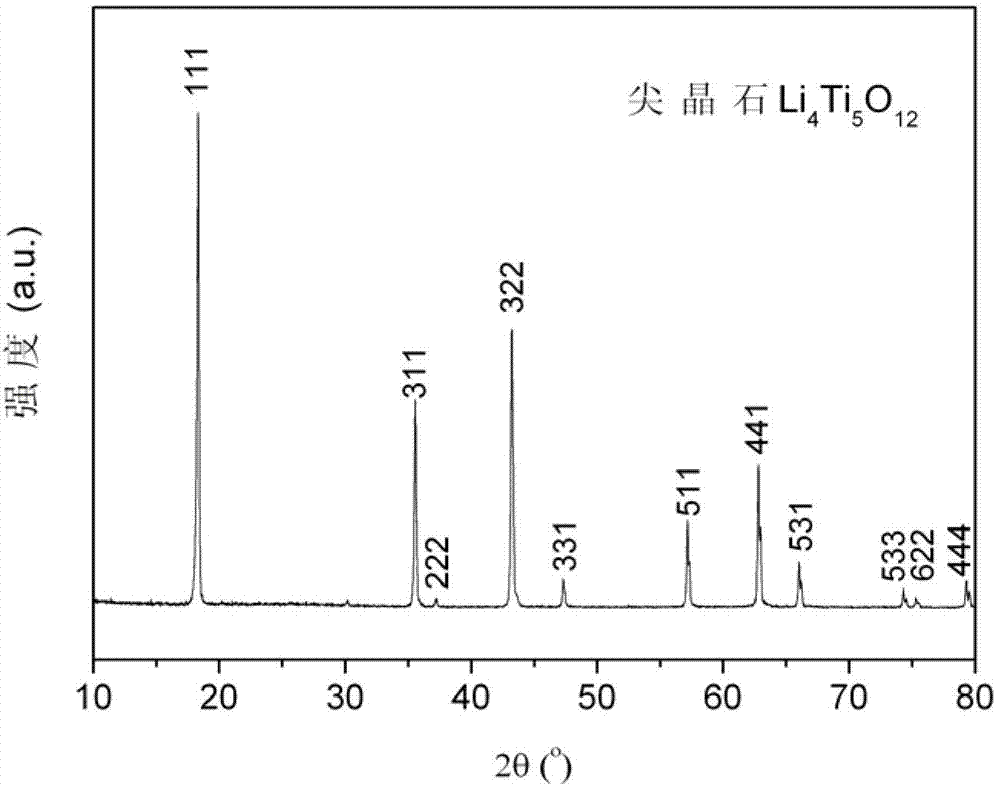

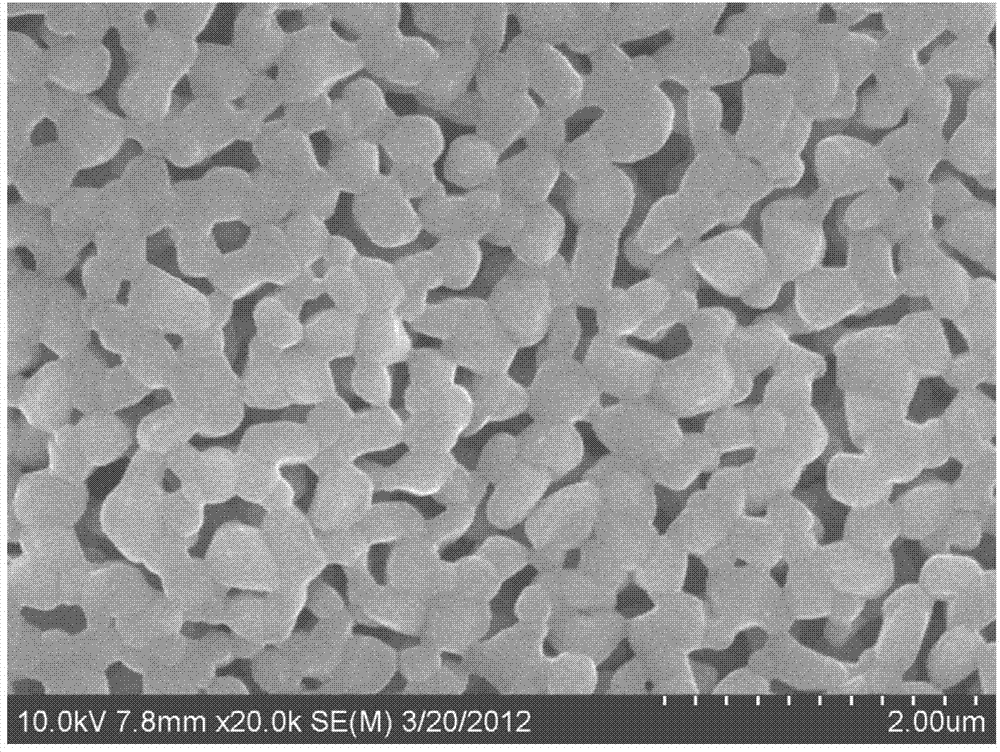

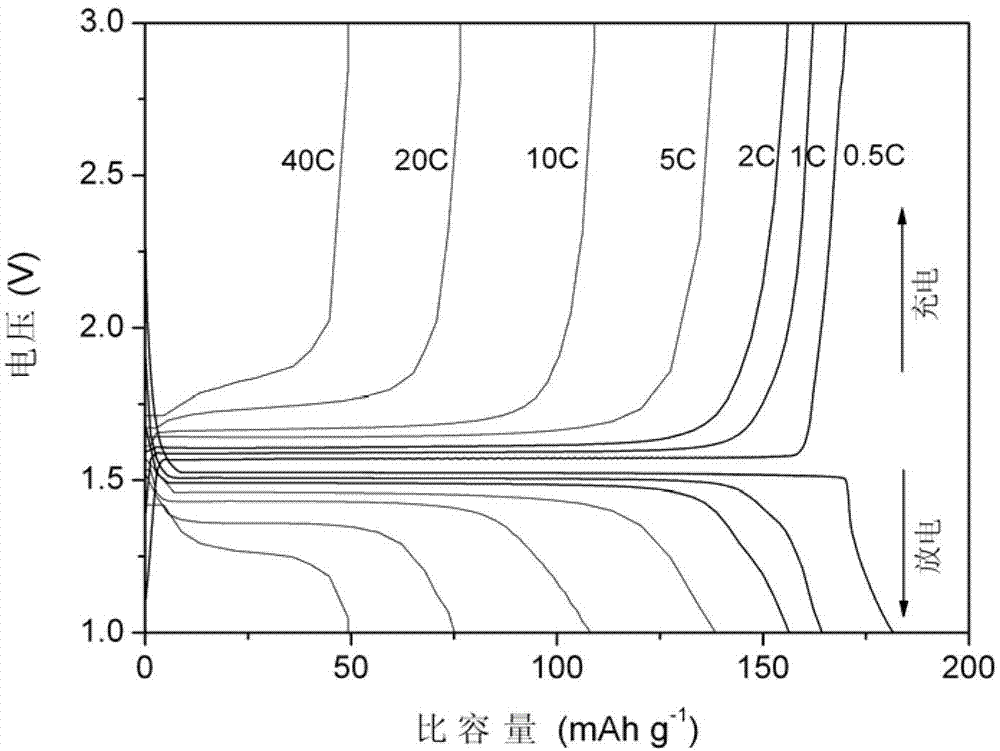

A kind of preparation method of lithium ion secondary battery anode material nanometer lithium titanate

A nano-lithium titanate, secondary battery technology, used in secondary batteries, battery electrodes, nanotechnology for materials and surface science, etc., can solve problems such as poor discharge performance at high rates, and achieve improved uniformity, Excellent rate performance and cycle stability, the effect of accelerated hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: First, premix 300 ml of ethanol and 30 ml of water according to the volume ratio of 1:0.1 to form a mixed solution, and then add 15 ml of HNO 3 As the inhibitor of follow-up reaction; Li and the compound of Ti, carry out batching according to the mol ratio of Li:Ti=4.2:5, take the tetra-n-butyl titanate (analytical pure) of 25.52 g, the lithium carbonate of 2.33 g ( analytically pure), added to the previous alcohol-water-acid mixture, stirred by a magnetic heating stirrer until completely dissolved; then 20 g of ethylenediaminetetraacetic acid and 30 g of citric acid were added to the pre-mixed metal ion solution After mixing evenly, add 100 ml of ammonia water dropwise to adjust the pH value to 8, and continue to stir; after the above mixed solution is stirred evenly to form a sol, heat and stir at 80 °C until it is in a gel state, and then dry it in a blast oven at 240 °C , to obtain a black and fluffy lithium titanate precursor; put the lithium titanate pr...

Embodiment 2

[0026]Example 2: According to the volume ratio of 1:0.1, 300 ml of ethanol and 30 ml of water were premixed to form a mixed solution, and then 15 ml of HCl was added as an inhibitor of the subsequent reaction; the compound of Li and Ti was prepared according to Li:Ti=4.2 :5 molar ratio for batching, weigh 21.31 g of tetraisopropyl titanate (analytical pure), 6.43 g of lithium acetate (analytical pure), join in the previous alcohol-water-acid mixture, heat the stirrer by magnetic force Stir until it is completely dissolved; then add 20 g of ethylenediaminetetraacetic acid and 40 g of citric acid into the premixed metal ion solution, mix well, add 100 ml of ammonia water dropwise to adjust the pH value to 9, and continue stirring; After the above mixed solution was stirred evenly to form a sol, it was then heated and stirred at 80°C until it reached a gel state, and then dried in a blast oven at 240°C to obtain a black and fluffy lithium titanate precursor; put the lithium titana...

Embodiment 3

[0027] Example 3: Premix 300 ml of ethanol and 60 ml of water according to the volume ratio of 1:0.2 to form a mixed solution, and then add 30 ml of HNO 3 As the inhibitor of follow-up reaction; Li and the compound of Ti, carry out batching according to the mol ratio of Li:Ti=4.4:5, take the tetra-n-butyl titanate (analytically pure) of 25.52 g, the lithium nitrate of 4.55 g ( analytically pure), added to the previous alcohol-water-acid mixture, stirred by a magnetic heating stirrer until completely dissolved; then 20 g of ethylenediaminetetraacetic acid and 60 g of citric acid were added to the pre-mixed metal ion solution After mixing evenly, add 110 ml of ammonia water dropwise to adjust the pH value to 7, and continue to stir; after the above mixed solution is stirred evenly to form a sol, heat and stir at 80°C until it reaches a gel state, and then dry it in a blast oven at 240°C , to obtain a black and fluffy lithium titanate precursor; put the lithium titanate precursor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com