Distributed battery management system and method for distributed battery management

A battery management system and battery management technology, applied in battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as communication obstacles of subordinate control departments, and achieve the effect of improving safety and reliability and saving manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

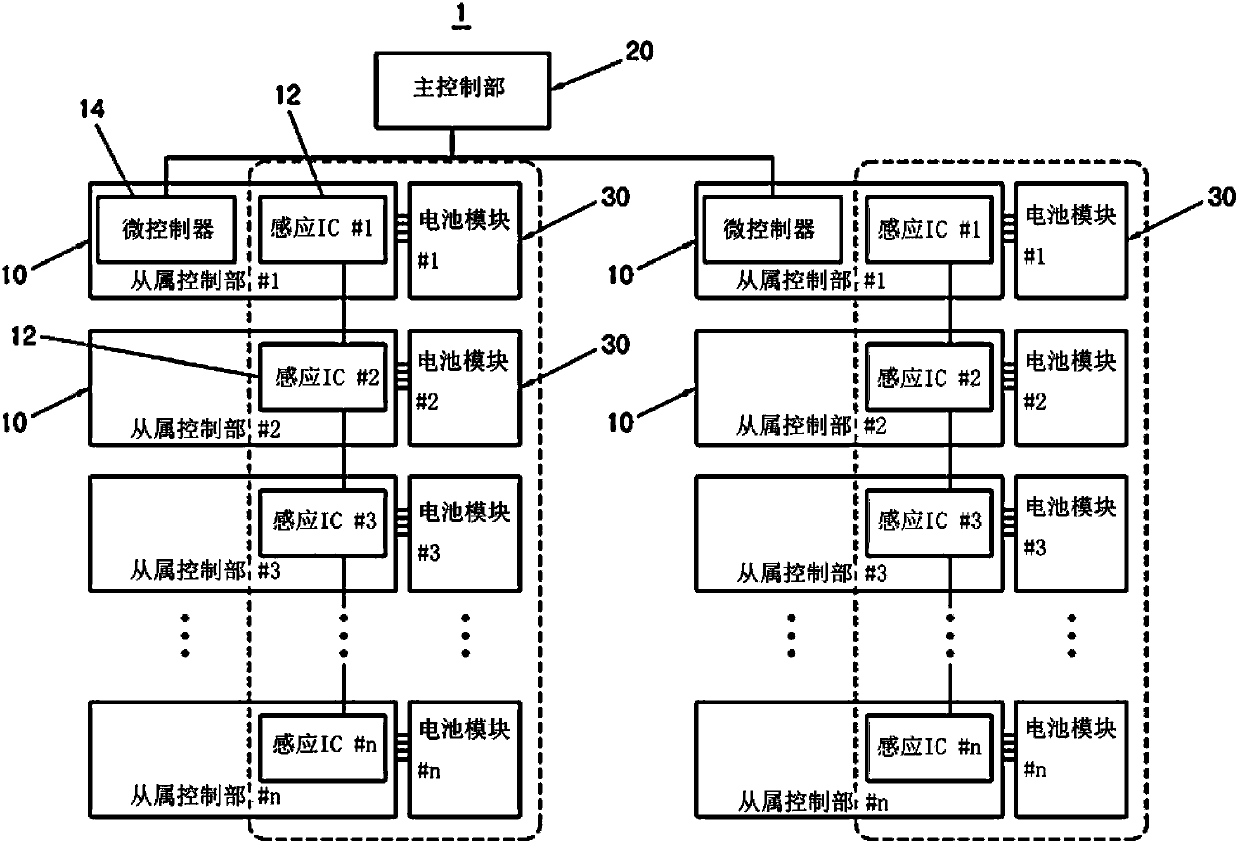

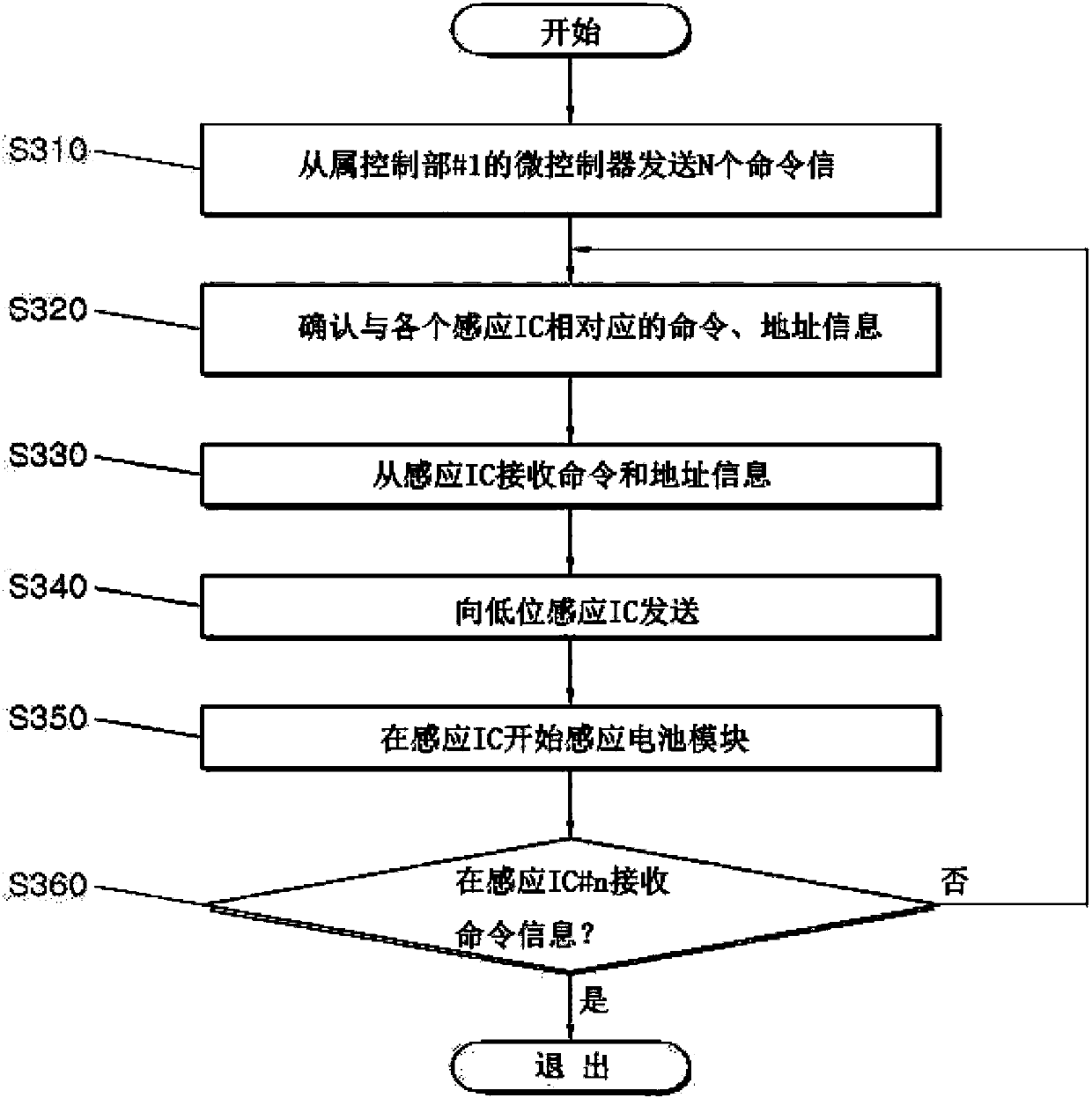

[0058] figure 1 It is a structural diagram of the distributed battery management system according to the first embodiment of the present invention, in which a plurality of slave control units 10 composed of two groups are shown. according to figure 1 , the distributed battery management system 1 of the first embodiment includes a plurality of slave control units 10 and a master control unit 20 composed of two groups, and each battery module 30 is connected to each corresponding plurality of slave control units 10 . Hereinafter, only the left group among the plurality of slave control units 10 will be described for convenience.

[0059] A plurality of slave control units 10 are arranged corresponding to the battery modules 30 respectively, and have a daisy chain structure in which the lowest slave control unit 10, #n to the highest slave control unit 10, #1 is connected in series.

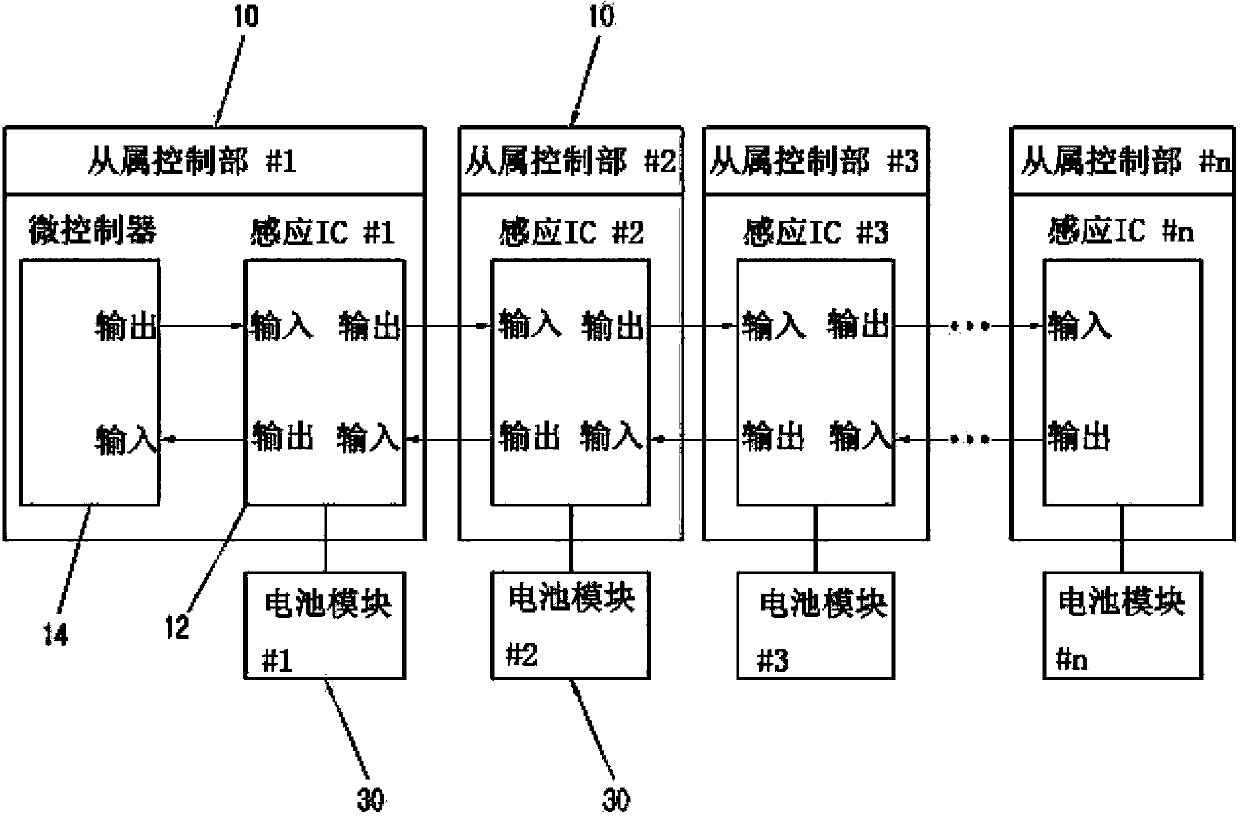

[0060] figure 2 It is a configuration diagram of a plurality of slave control units in the f...

no. 2 example

[0079] Figure 7 It is a structural diagram of the distributed battery management system of the preferred second embodiment of the present invention.

[0080] according to Figure 7 , the distributed battery management system of the present invention includes encoding the control information transmitted by the master control unit 20 into an asynchronous differential signal, and decoding the differential signal corresponding to the sensing information encoded into the control information transmitted by each slave control unit 10 Interface IC100.

[0081] The highest-order slave control unit 10, #1 may include a microcontroller 200 in addition to the sensor IC 12. The microcontroller 200 receives the control information #1-#n used to control the operation of the slave control unit 10, and collects the sensing information #2-#n of a plurality of slave control units 10, #2-#n in the low order, and the sensing information #2-#n related to its own induction. Sensing information #...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com