Double-wall insulation silo with stiffening ribs and production method thereof

A technology of stiffeners and heat preservation cylinders, applied in the field of heat preservation granaries, can solve the problems of poor heat insulation performance, low strength, and difficulty in popularization of ordinary steel plate silos, so as to ensure strength characteristics and system rigidity, improve service life, and increase rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

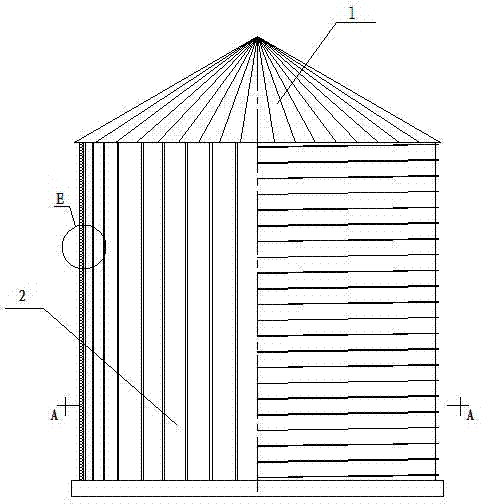

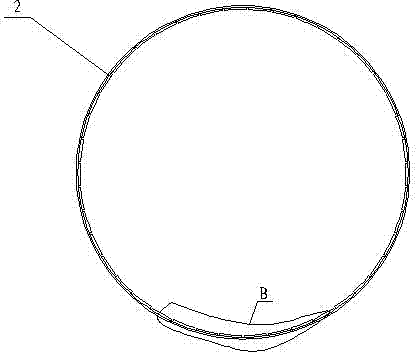

[0033] A double-wall thermal insulation silo with stiffening ribs, which consists of: a roof 1, a body 2 connected to the roof, the body includes an inner wall 3 and an outer wall 4, and the inner wall has stiffening Ribs 5, an insulating layer 6 is provided between the inner wall and the outer wall.

Embodiment 2

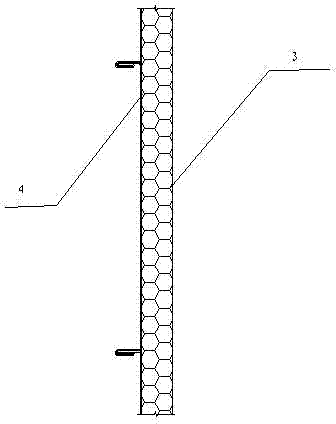

[0035] In the double-wall thermal insulation silo with stiffeners described in Example 1, the stiffeners are grooves whose height is the height of the insulation layer, and the outer wall and the inner wall pass through the stiffeners 5 Bolt or rivet connections.

Embodiment 3

[0037] In the double-wall thermal insulation silo with stiffening ribs described in embodiment 1 or 2, the inner wall includes a set of inner wall panels connected end to end, and the two sides of the inner wall panels have Z-shaped connecting strips 7, the There is a group of connection holes 8 on the Z-shaped connection belt, and the adjacent inner wall panels are fixed to the outer wall by bolts 9 or rivets passing through the connection holes, and the Z-shaped overlap of the inner wall panels The groove-shaped stiffener is formed at the place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com