Roll allocation method and device for optimization of roll pass system

A technology for system optimization and roll matching, which is applied in the direction of rolls, guide/positioning/alignment devices, metal rolling, etc., to achieve the effects of saving capital, simplifying devices, and reducing the number of adjustments and trial rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

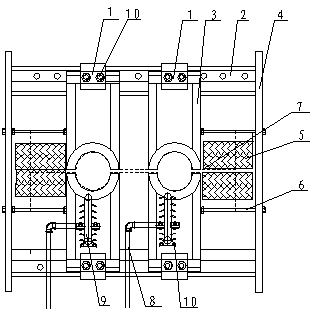

[0020] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

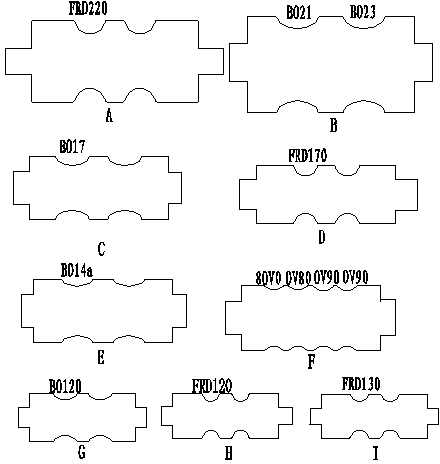

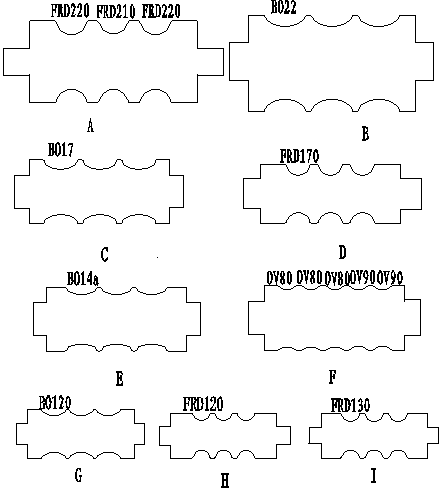

[0021] Roll matching method and roll matching device for roll pass system optimization, including three types of rolls with specifications of φ610*760, φ770*1000, and φ860*1200. For semi-steel rolls with a carbon content of 1.6%, on the premise of ensuring that the roll ring insurance coefficient is 0.6-0.9, add a rolling groove to the rolls of the above three specifications, and the cross-sectional area of the rolling groove is less than or equal to that of the above three specifications. The cross-sectional area of the rolling groove that the roll itself has; figure 2 Shown:

[0022] 1. On roll A of Φ860*1200, there are two rolling grooves of FRD220 and one rolling groove of FRD210. Compared with the existing technology, one rolling groove of FRD210 is added, and the added r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com