Designing and manufacturing method of pad tile for adjusting aviation engine blade rolling

An aero-engine and design method technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as damage to rolling mills, and achieve significant economic benefits, low production costs, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

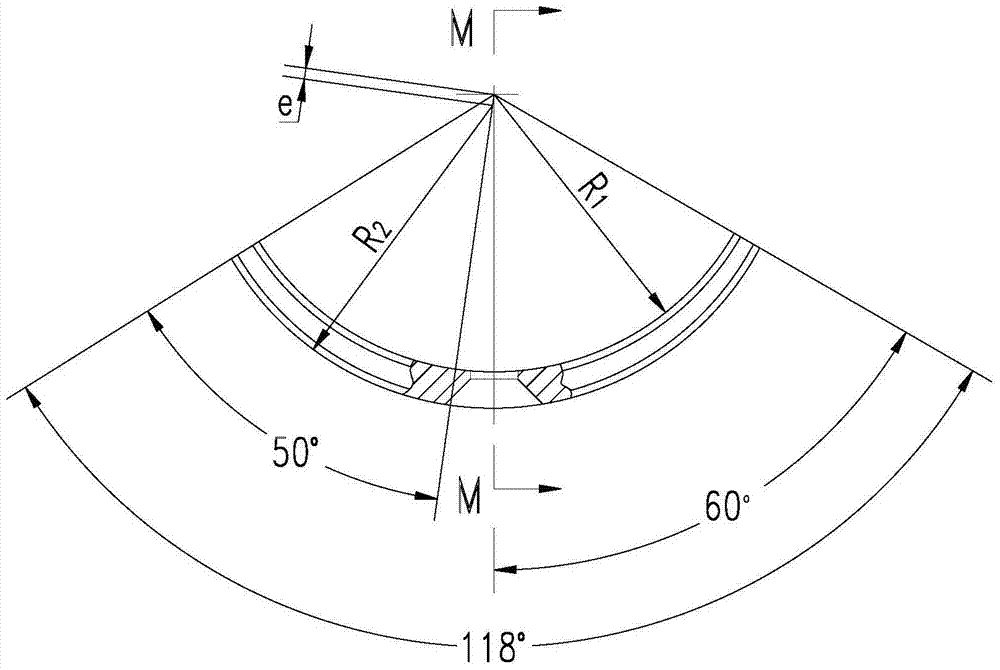

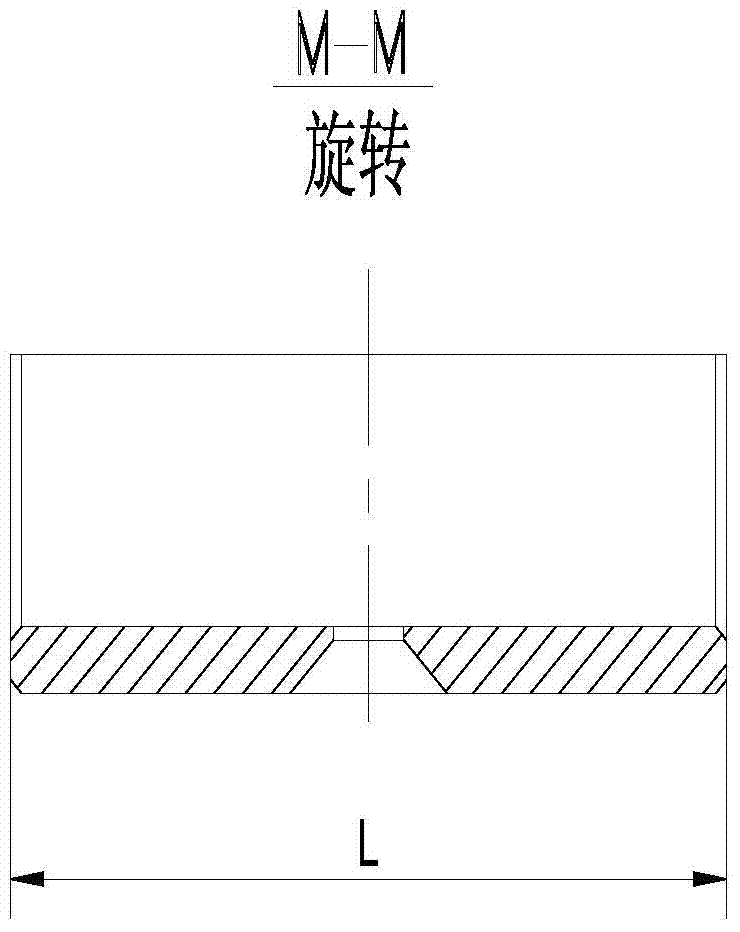

[0030] This embodiment is a design method of pad tiles for rolling adjustment of a certain type of aeroengine blade, which is carried out according to the following steps:

[0031] Step 1. Feasibility analysis of adjusting the thickness of a certain type of aero-engine blade rolling die with pad tiles

[0032] During the rolling process of this type of aero-engine blade, the mold surface needs to be repaired due to the unqualified rolling of the mold surface or the wear of the mold surface, resulting in a reduction in the thickness of the mold. If it continues to be used, the rolled blade thickness will be reduced. increase failed. When the amount of trimming on one side of the mold is greater than 0.15mm, the mold must be scrapped. Add pads between the inner diameter of the mold and the roll shaft after the thickness is reduced, which can fit well with the roll shaft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com