Large-tonnage movable trolley with convertible load distribution

A large-tonnage, moving technology, applied in the transportation of passenger cars, transportation and packaging, railway car body parts, etc., can solve the problems of high purchase, use and maintenance costs of handling machines, long equipment processing cycle, and short service life. , to achieve uniform load distribution, reduce production costs and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

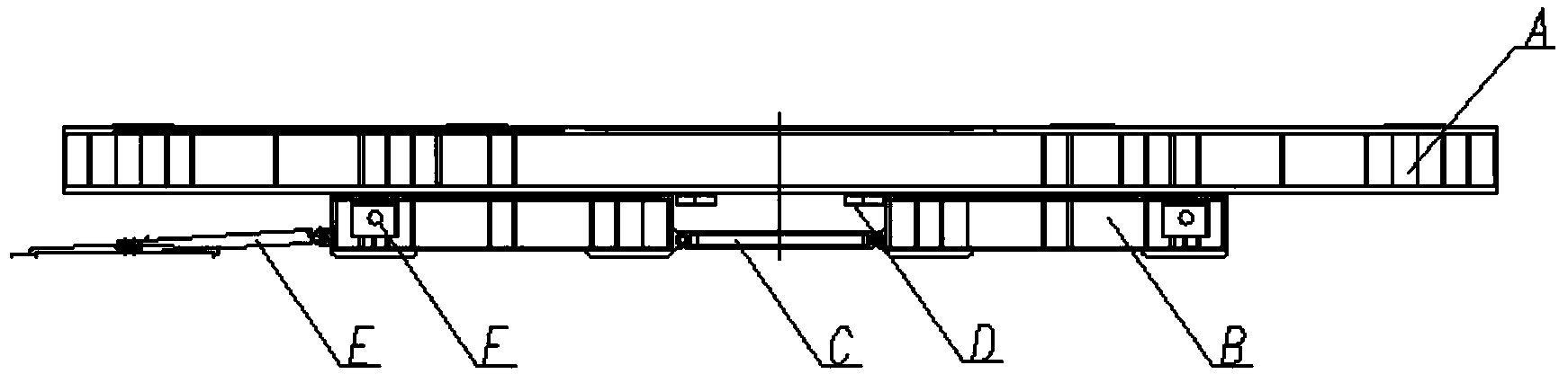

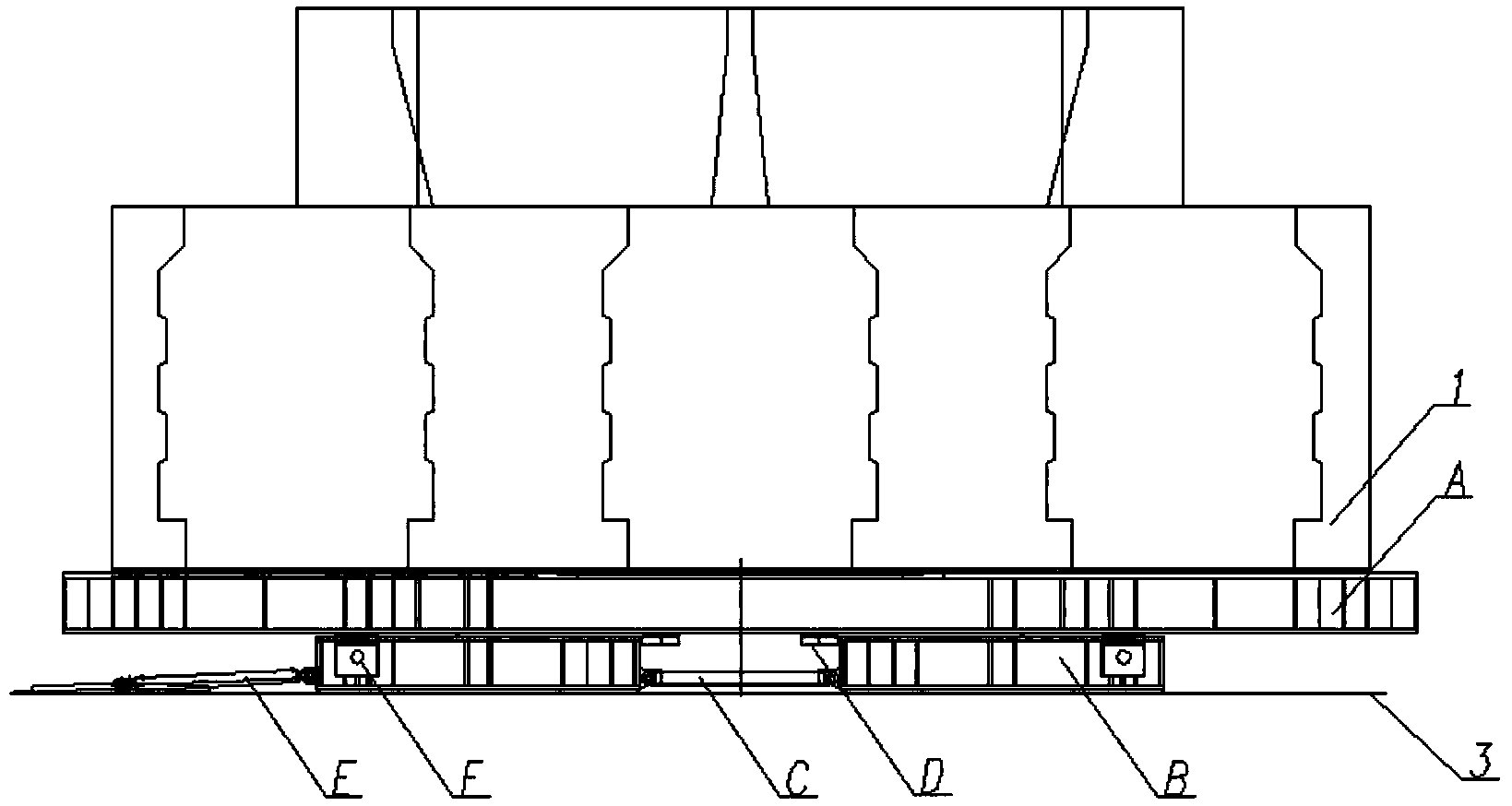

[0017] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

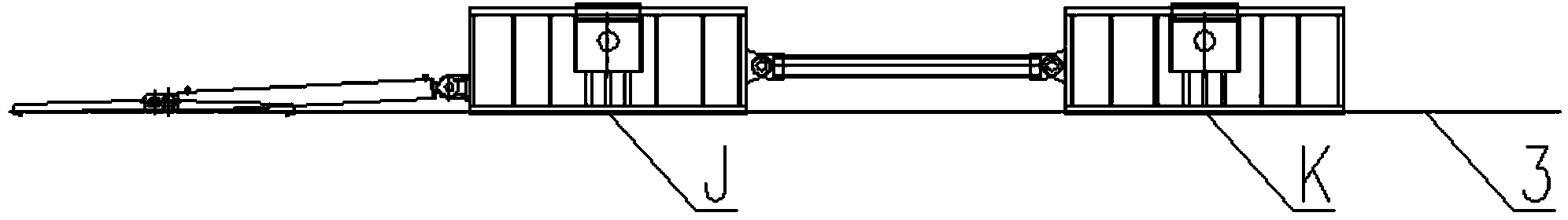

[0018] The present invention is a large tonnage displacement trolley capable of load conversion and distribution, which is composed of two sets of unilateral transport trolleys, a PLC control system and a hydraulic pump station. The side shift trolley is composed of the upper beam, the lower beam, the support plate, the jacking cylinder and the traveling cylinder. The traveling cylinder E and the jacking cylinder F are respectively connected to the corresponding hydraulic pump stations, and the traveling cylinder E is connected to the transfer trolley. ;The lower beam is composed of two identical lower distribution beams B, the two lower distribution beams B are horizontally spaced apart, their inner ends are connected by connecting rods C, and their outer ends are respectively equipped with jacking cylinders F, the upper beam A, two The center lines of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com