An anti-sticking and smooth activated cloth device

A distribution device and smooth technology, applied in the field of solid particle material feeding equipment, can solve the problems of poor feeding by the superior, rigid vibration of the self-vibration device, easy blocking of channels, etc., and achieve high-precision quantitative feeding and stable quantitative feeding. , the effect of reducing the sticking situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and examples.

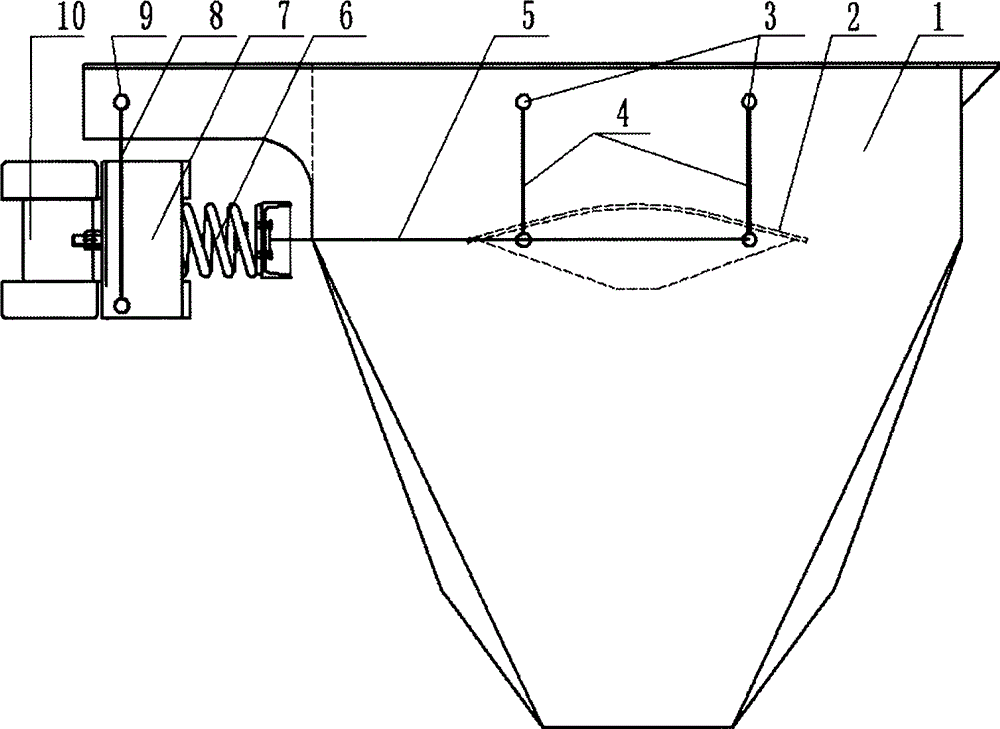

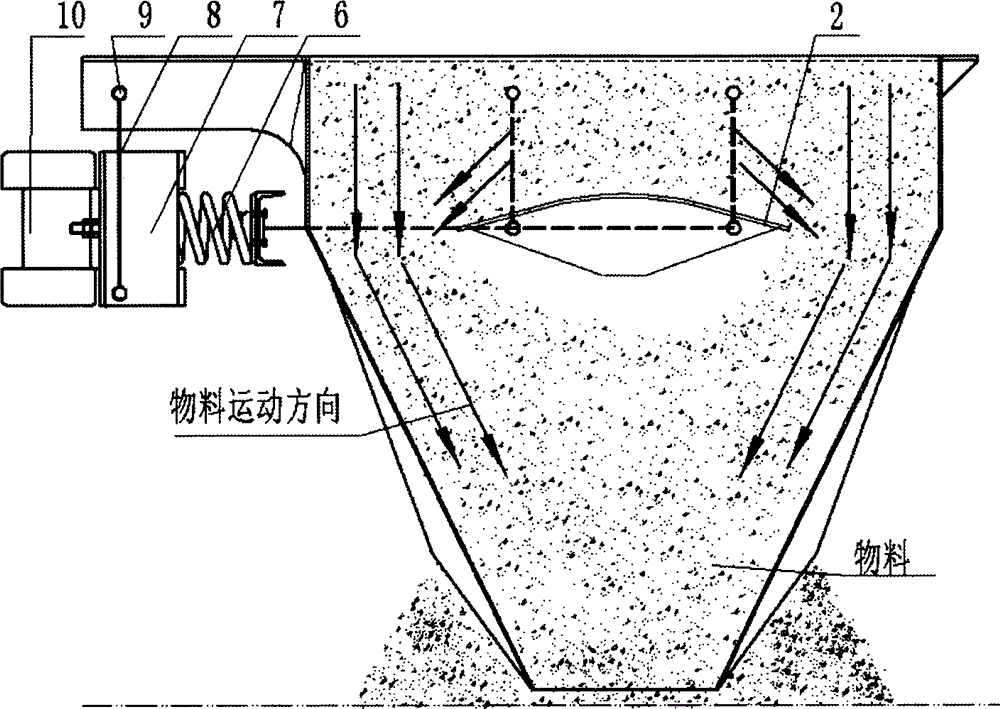

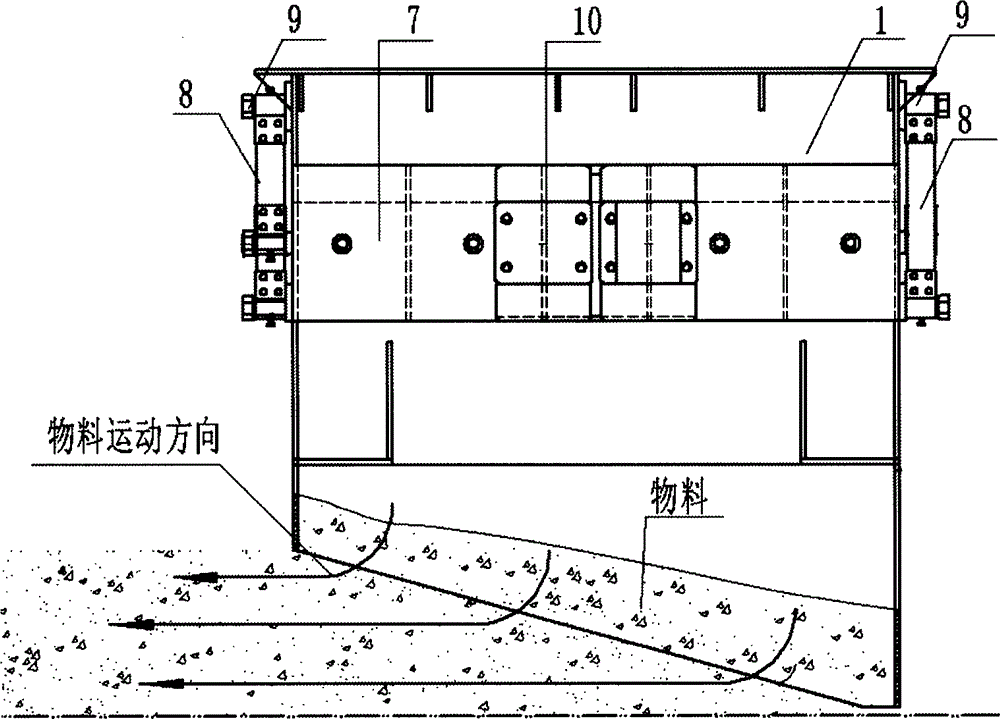

[0015] to combine figure 1 , a kind of anti-sticking and smooth activation distributing device that the present invention proposes, it comprises distributing device (1), activation cone (2), activation cone suspension shaft (3), activation cone suspension arm (4), connecting rod (5) , exciting spring (6), exciting body (7), exciting body boom (8), exciting body hanging shaft 9 and vibrating motor (10), wherein: the distributor (1) is arranged on the outer silo Below, the activation cone (2) is set in the distributor (1), and the activation cone (2) is connected with the distributor (1) by the activation cone boom (4) and the activation cone suspension shaft (3); the vibrating motor (10 ) is fixedly connected with the vibrating body (7), and is connected with the distributor (1) through the vibrating body boom (8) and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com