Enthalpy-increasing continuous combustion propelling device

A propulsion device, self-increasing technology, applied in the field of launch, can solve the problems of complex operation, overheating, large current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

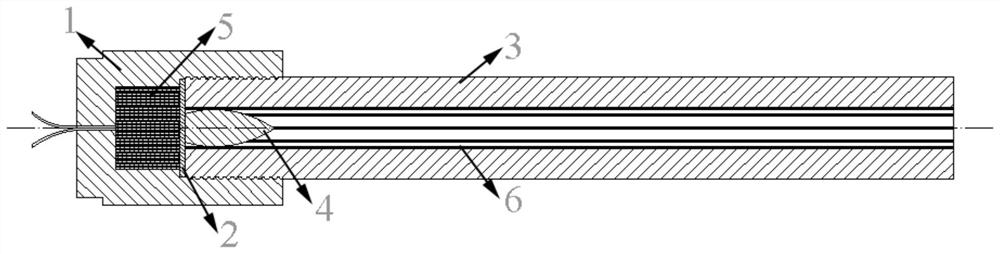

[0027] refer to figure 1 , first select the body tube 3, process a rectangular groove inside the body tube 3, carry out the groove charge 6, and place the projectile 4 at one end of the body tube 3; then carry out the propellant charge in the launching mechanism 1, Place the tablet 2 between the launch mechanism 1 and the barrel 3; then insert a section of the combined barrel with the projectile 4 into the launch mechanism 1 through threads; then fix the installed device; Detonate.

Embodiment 2

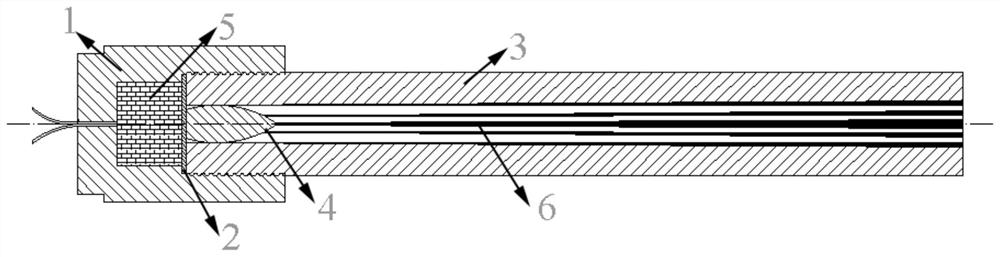

[0029] refer to figure 2 , first select the barrel 3, process it into a groove with gradually increasing size inside the barrel 3, carry out the groove charge 6, and place the projectile 4 at one end of the barrel 3; then carry out the propellant in the launching mechanism 1 Charge the medicine, place the medicine blocking piece 2 between the launch mechanism 1 and the barrel 3; then insert a section of combined barrel with the projectile 4 into the launch mechanism 1 through threads; then fix the installed device; finally pass the launch The detonator detonates.

Embodiment 3

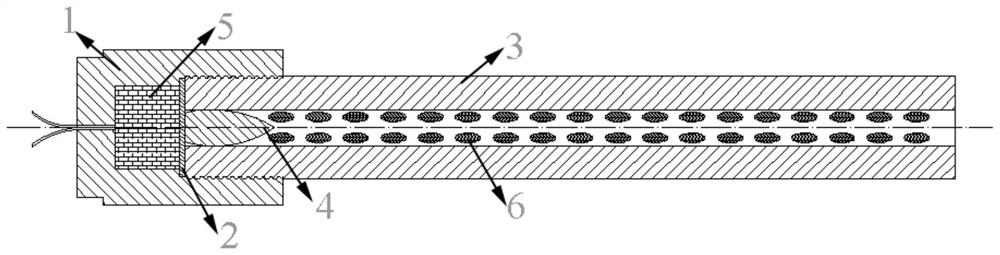

[0031] refer to image 3 , first select the barrel 3, inside the barrel 3 there are pits of a certain size and depth, the pits are arranged in a spiral distribution, carry out the pit charge 6, and place the projectile 4 at one end of the barrel 3; then launch Carry out the propellant charge in the mechanism 1, place the drug blocking sheet 2 between the launching mechanism 1 and the barrel 3; then insert a section of combined barrel with the projectile 4 into the launching mechanism 1 through threads; then place the installed The device is fixed; finally detonated by the detonator.

[0032]In each of the above-mentioned embodiments, the high-temperature and high-pressure gas produced by the propellant in the launching mechanism 1 under the action of the detonator will shear the drug blocking piece 2 along the axial direction of the barrel 3, so that the cut circle The sheet pushes the projectile 4 to move at high speed under the action of high-pressure gas, which ensures a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com