A kind of vinyl-terminated amphiphilic fluorine-containing graft polymer composite photocurable coating and preparation method

A technology of grafting polymers and curing coatings, applied in epoxy resin coatings, coatings, etc., can solve the problems of low reaction temperature, poor solubility of fluoropolymers and solvents, limited modification effect, etc., to improve hydrophobicity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

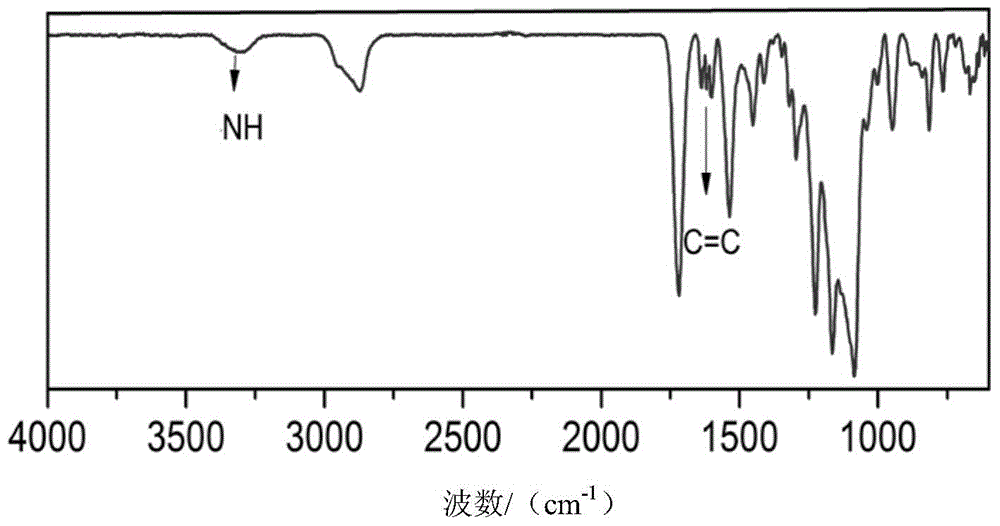

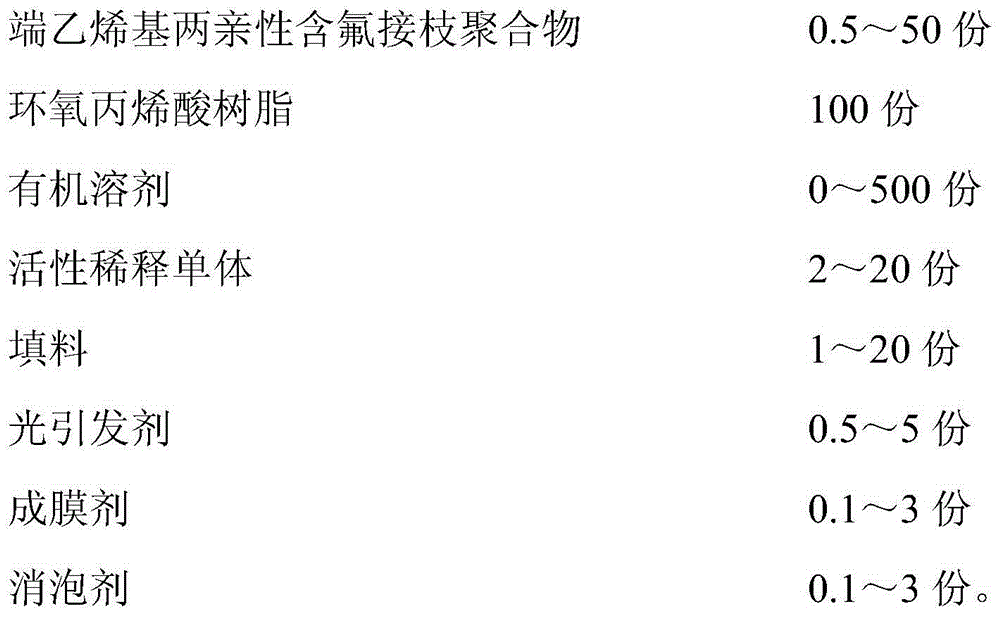

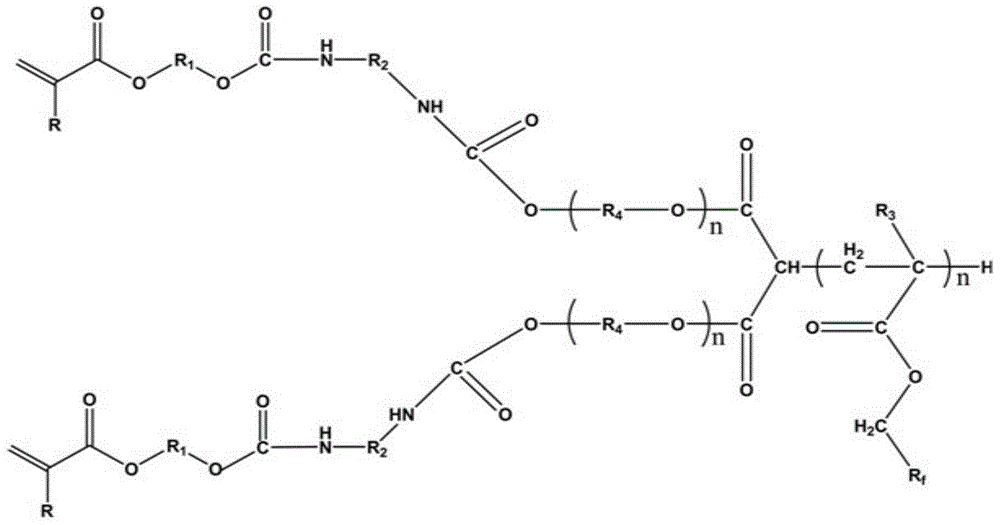

Image

Examples

Embodiment 1

[0043](1) Carboxyl-terminated hexafluorobutyl methacrylate polymer is prepared by the following method: 1 mass part of tert-butyl malonate, 100 mass parts of toluene and 5 mass parts of tetrabutylammonium hydroxide aqueous solution with a concentration of 25wt% Mix well, react at 50°C for 10 hours, remove toluene under reduced pressure, then add 60 parts by mass of tetrahydrofuran and 6 parts by mass of hexafluorobutyl methacrylate, react for 1 hour, remove tetrahydrofuran under reduced pressure, and place the obtained product in Hydrolyze in a mixed solution of 8 parts by mass of trifluoroacetic acid and 60 parts by mass of dioxane at 80°C for 10 hours to obtain a carboxyl-terminated hexafluorobutyl methacrylate polymer.

[0044] Through gel permeation chromatography (GPC) analysis, the number average molecular weight M of the polymer is measured n =3240.

[0045] (2) The amphiphilic fluorine-containing graft polymer terminated by hydroxyl groups is prepared by the following...

Embodiment 2

[0052] (1) Carboxy-terminated dodecafluoroheptyl acrylate polymer was prepared by mixing 1 mass part of tert-butyl malonate, 100 mass parts of toluene and 5 mass parts of a 25 wt% tetrabutylammonium hydroxide aqueous solution Evenly, react at 50°C for 10h, remove toluene under reduced pressure, then add 60 parts by mass of tetrahydrofuran and 15 parts by mass of dodecafluoroheptyl acrylate, react for 1h, remove tetrahydrofuran under reduced pressure, and place the obtained product at 80°C 8 mass parts of trifluoroacetic acid and 60 mass parts of dioxane mixed solution were hydrolyzed for 10 h to obtain dodecafluoroheptyl carboxy-terminated acrylate polymer. Number average molecular weight M measured by gel permeation chromatography (GPC) n =3680

[0053] (2) Amphiphilic fluorine-containing graft polymers terminated by hydroxyl groups are prepared by the following method: 100 parts by mass of dodecafluoroheptyl acrylate polymers terminated with carboxyl groups, polypropylene g...

Embodiment 3

[0058] (1) Carboxy-terminated trifluoroethyl acrylate polymer was prepared by the following method: 1 mass part of tert-butyl malonate, 100 mass parts of toluene and 5 mass parts of tetrabutylammonium hydroxide aqueous solution with a concentration of 25wt% were uniformly mixed , reacted at 50°C for 10h, removed toluene under reduced pressure, then added 60 parts by mass of tetrahydrofuran and 3 parts by mass of trifluoroethyl acrylate, reacted for 1h, removed tetrahydrofuran under reduced pressure, and placed the obtained product in 8 mass parts at 80°C Parts of trifluoroacetic acid and 60 parts by mass of dioxane mixed solution were hydrolyzed for 10 hours to obtain carboxyl-terminated trifluoroethyl acrylate polymer. Number average molecular weight M measured by gel permeation chromatography (GPC) n =1870

[0059] (2) The amphiphilic fluorine-containing graft polymer terminated by hydroxyl groups is prepared by the following method: 100 parts by mass of carboxyl-terminated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alkali resistance | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com