Lightweight combined-type plate structure used for low-frequency noise insulation and design method of lightweight combined-type plate structure

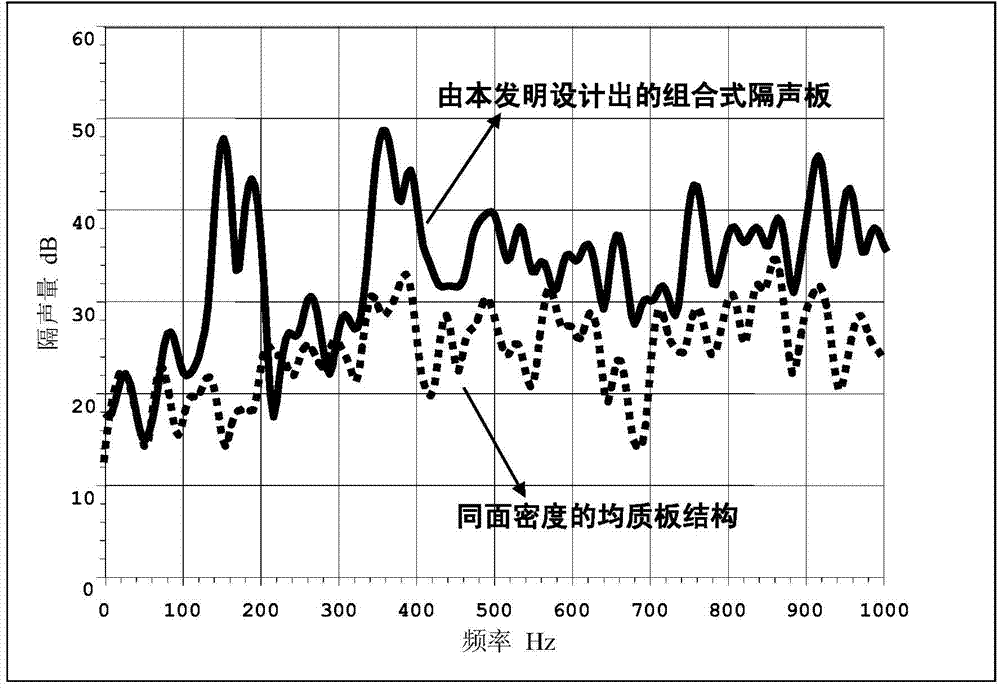

A design method and combined technology, applied in the direction of sound insulation, building components, etc., can solve problems such as the quality of sound insulation components, cost constraints, etc., to achieve the effect of improving the overall isolation effect, reducing radiation noise, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

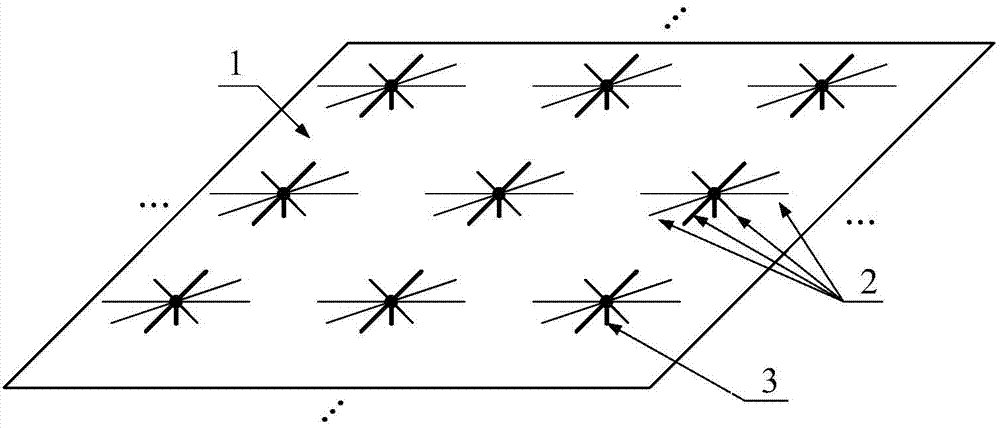

[0034] The present invention is a lightweight combined panel structure for low-frequency sound insulation, such as figure 1 As shown, the device is composed of a sound insulation substrate 1, a beam unit and a support member 3; the beam unit is fixedly connected on the sound insulation substrate 1 through the support member 3, and the beam unit includes at least one beam 2 in a rectangular parallelepiped structure, and the beam unit The center points of the sheets 2 are all fixedly connected with the support member 3; the lowest order resonant frequency of a beam sheet 2 is the same as a target noise frequency.

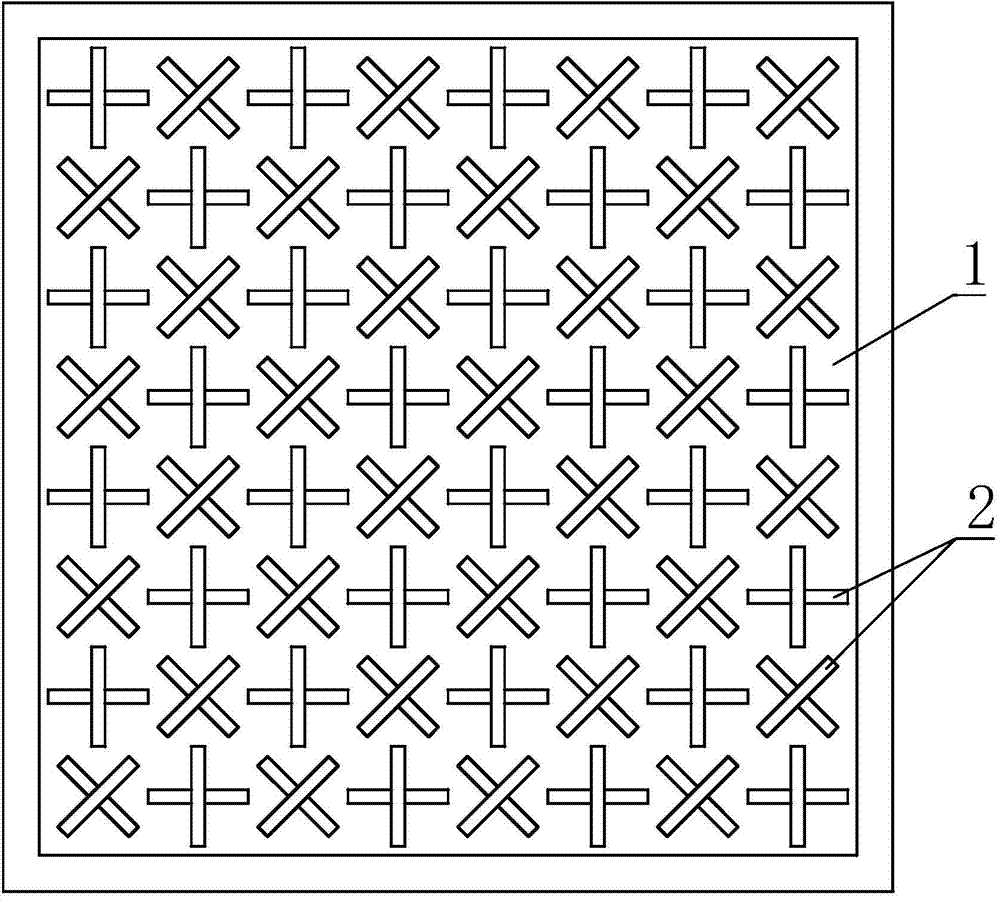

[0035] Such as figure 2 As shown, in this preferred embodiment, the beam units are additionally arranged in a periodic array on the sound insulation substrate 1; the beam unit incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com