Signal detection processing circuit for perforation ignition control circuit

An ignition control and signal detection technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve problems such as circuit short circuit, perforating gun rupture, failure to realize the dual functions of address query and ignition, etc., and achieve The effect of protecting the ignition and detonation circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

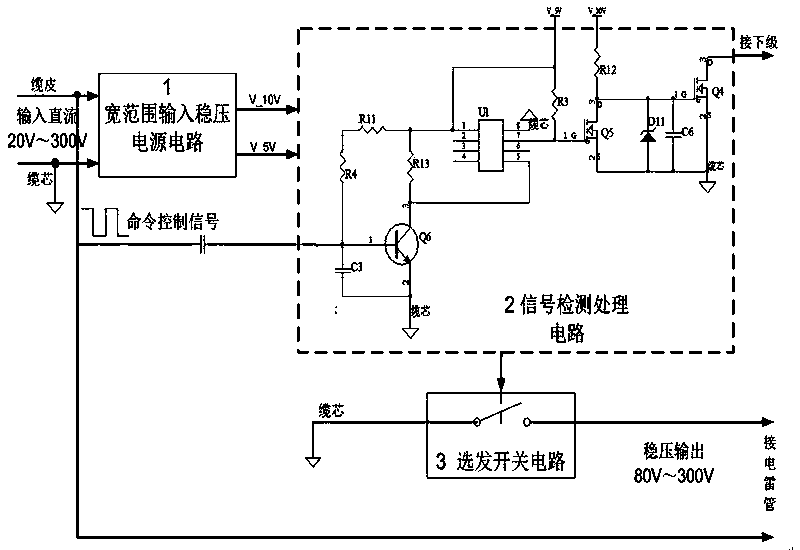

[0020] Refer to the attached figure 1 , the best embodiment of the present invention is: the signal detection processing circuit 2 of the present invention is composed of resistors R3, R4, R11, R12, R13, capacitors C3 and C6, diode D11, transistor Q6, field effect transistors Q4, Q5, SCM U1 composition. R4, R11, R13, C3 and Q6 form an amplifying circuit, which is used to amplify the command signal, output from the collector of Q6, the 5th pin of U1 is connected to the collector of Q6, the 1st pin of U1 is connected to the 5V power supply, and the 8th pin Connect the cable core (ground), connect one end of R3 and the gate of Q5 with pin 7, connect the other end of R3 to a 5V power supply, connect one end of R12 to a 10V power supply, and connect the other end to the drain of Q5, the cathode of D11, one end of C6 and the gate of Q4 The source of Q5 is connected to the anode of D11, the other end of C6 and the source of Q4 are connected to the cable core (ground).

Embodiment 2

[0022] The present invention is applied to an ignition control circuit of an electric detonator in a downhole, and the circuit includes a wide-range input regulated power supply circuit 1, a signal detection and processing circuit 2, and a selective firing switch circuit 3;

[0023] Wide-range input regulated power supply circuit 1 is used to input 20V to 40V DC power to the downhole ignition control circuit through a single-core cable from the surface system, and output 10V and 5V DC power after being stabilized by wide-range input regulated power supply circuit 1, which is used as a signal The detection processing circuit 2 and the ignition switch circuit supply power; ensure their normal operation;

[0024] The signal detection processing circuit 2 receives the ignition control command from the ground system, and controls the conduction and disconnection of the selective firing switch circuit 3 according to the command, and controls the detonation of the electric detonator; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com