Ignition control circuit of downhole electric detonator for perforation

An ignition control, electric detonator technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of perforating gun rupture, electric detonator detonation, circuit short circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

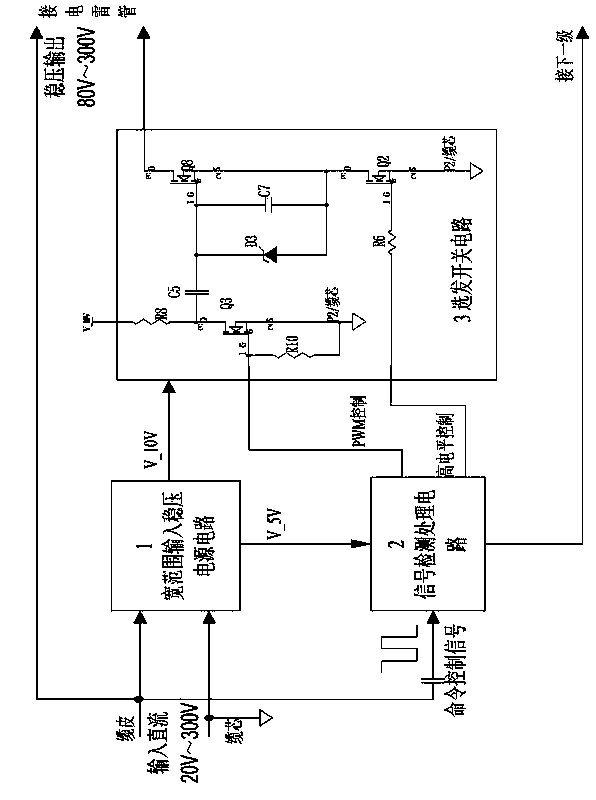

[0030] Refer to the attached figure 1 , A preferred embodiment of the present invention is: the hair selection switch circuit 3 of the present invention is composed of resistors R6, R8, R10, capacitors C5, C7, Zener diode D3, field effect transistors Q2, Q3, Q8. The connection relationship is: the gate of Q3 is connected to the PWM control terminal of the signal detection control circuit; one end of R10 is connected to the gate of Q3, the other end is connected to the source of Q3 and grounded; one end of R8 is connected to 10V power supply, and the other end is connected to the drain of Q3; one end of C5 is connected to The drain of Q3, the other end is connected to the grid of Q8, the cathode of D3 is connected to the grid of Q8, and the anode is connected to the drain of Q2; one end of C7 is connected to the grid of Q8, and the other end is connected to the source of Q8; the drain of Q8 is connected to one end of the electric detonator; one end of R6 Connect to the high-lev...

Embodiment 2

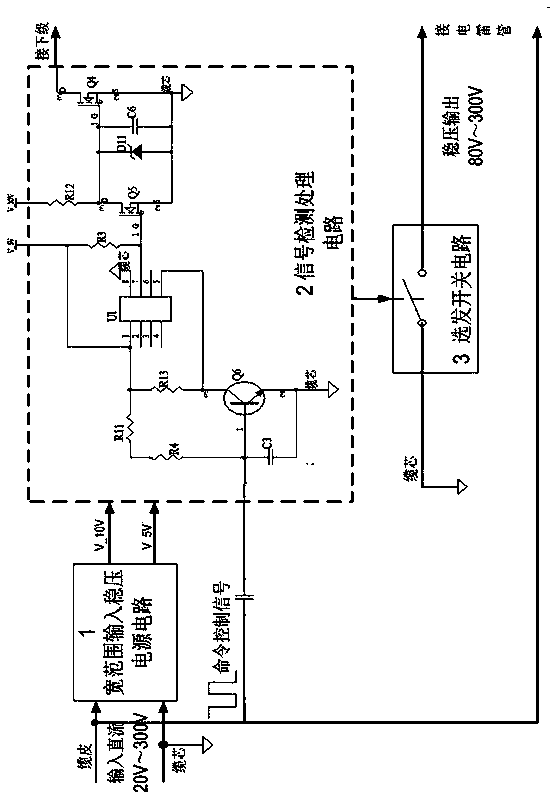

[0034] Refer to the attached figure 2 Another preferred embodiment of the present invention is: the signal detection processing circuit 2 of the present invention is composed of resistors R3, R4, R11, R12, R13, capacitors C3, C6, diode D11, transistor Q6, field effect transistor Q4, Q5 is composed of single-chip microcomputer U1. R4, R11, R13, C3 and Q6 form an amplifying circuit, which is used to amplify the command signal, output from the collector of Q6, the 5th pin of U1 is connected to the collector of Q6, the 1st pin of U1 is connected to the 5V power supply, and the 8th pin Connect the cable core (ground), connect one end of R3 and the gate of Q5 with pin 7, connect the other end of R3 to a 5V power supply, connect one end of R12 to a 10V power supply, and connect the other end to the drain of Q5, the cathode of D11, one end of C6 and the gate of Q4 The source of Q5 is connected to the anode of D11, the other end of C6 and the source of Q4 are connected to the cable c...

Embodiment 3

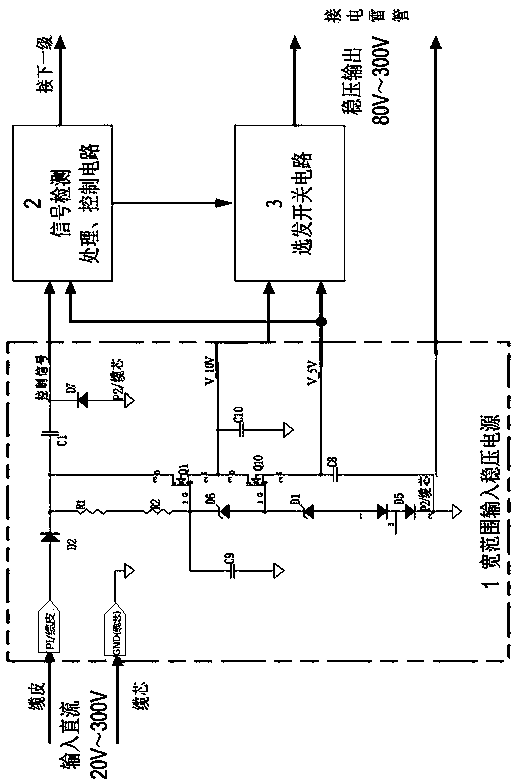

[0038] Refer to the attached image 3 , another preferred embodiment of the present invention is: wide-range input regulated power supply circuit 1 includes five diodes D1, D2, D5, D6, D7; two resistors R1 and R2; four capacitors C1, C8, C9, C10; 2 CMOS field effect transistors Q1, Q10. The connection relationship is: the anode of D2 is connected to the cable sheath, the cathode is connected to one end of R1, the other end of R1 is connected to one end of R2, the other end of R2 is connected to the grid of Q1, one end of C1 and the cathode of D6. The other end of C1 is connected to the cable core (ground), the anode of D6 is connected to the grid of Q10 and the cathode of D1, the anode of D1 is connected to the anode of D5, and the cathode of D5 is connected to the cable core (ground). The drain of Q10 is connected to one end of R1 and one end of C1, the other end of C1 is connected to the cathode of D7, and the anode of D7 is connected to the cable core (ground); the source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com