Temperature control device and control method for pumping hydraulic system and engineering machinery

A technology of a temperature control device and a temperature control method, which is applied to fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., and can solve problems such as large output displacement and power waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

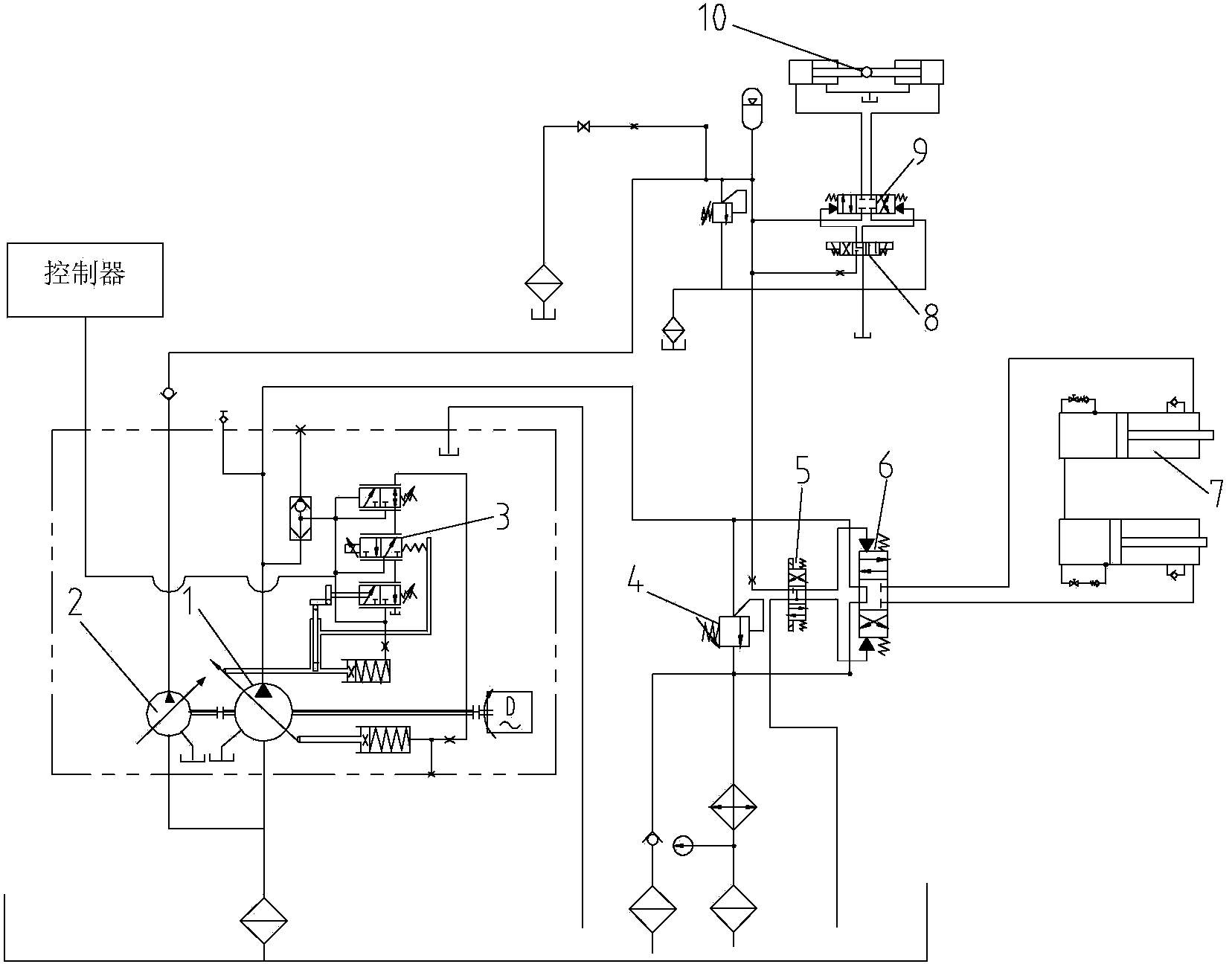

[0024] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0025] In this embodiment, the displacement gears of the hydraulic pump are divided into high and low gears. For example, if the displacement gears are divided into 5 gears, the 1st and 2nd gears are low gears, and the 3rd, 4th, and 5th gears are high gears. , if the displacement gears are divided into 4 gears, then the 1st and 2nd gears are low gears, and the 3rd and 4th gears are high gears. The division of gears here is based on the general understanding of those skilled in the art. The situation is determined by the operator himself.

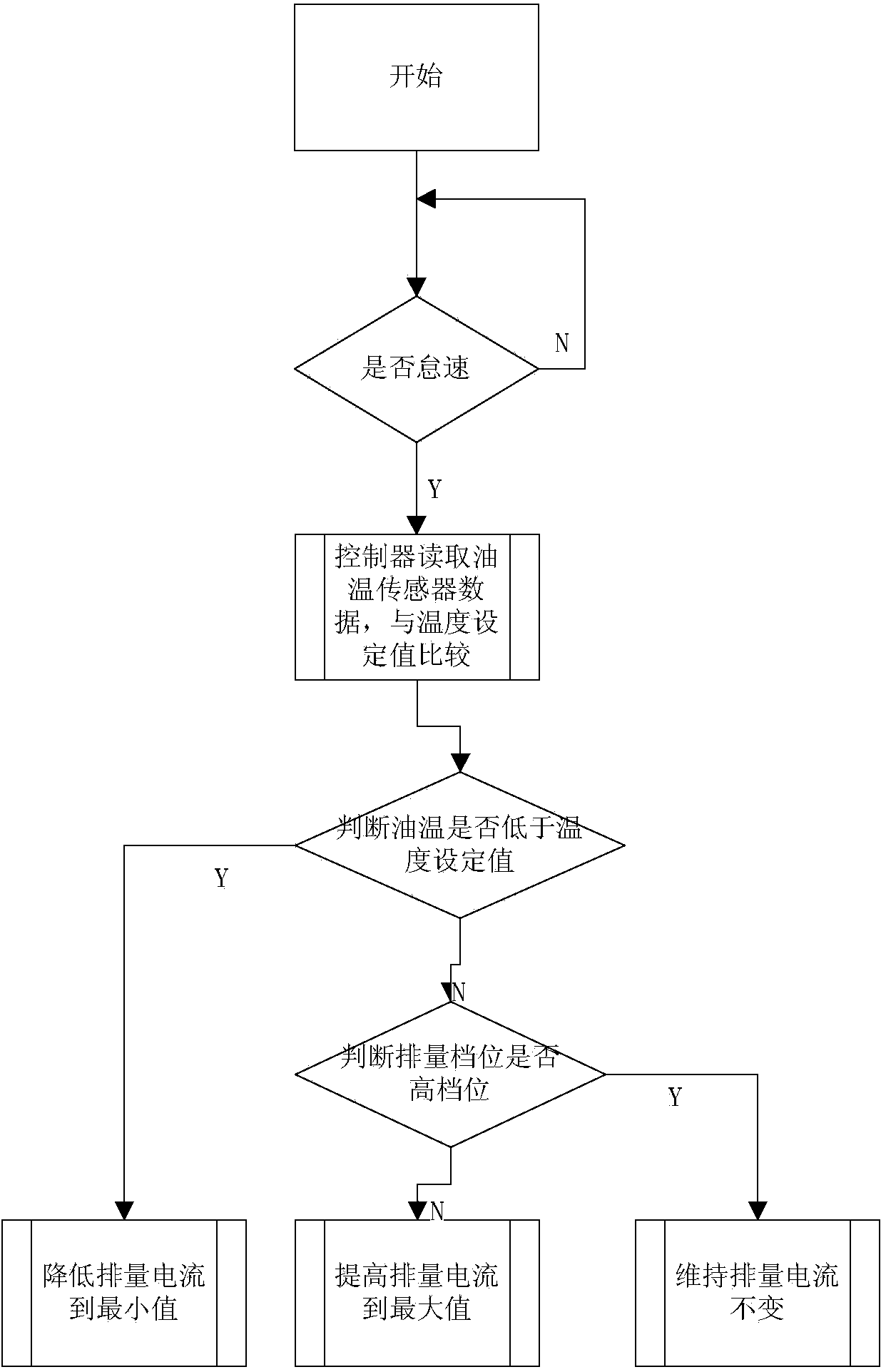

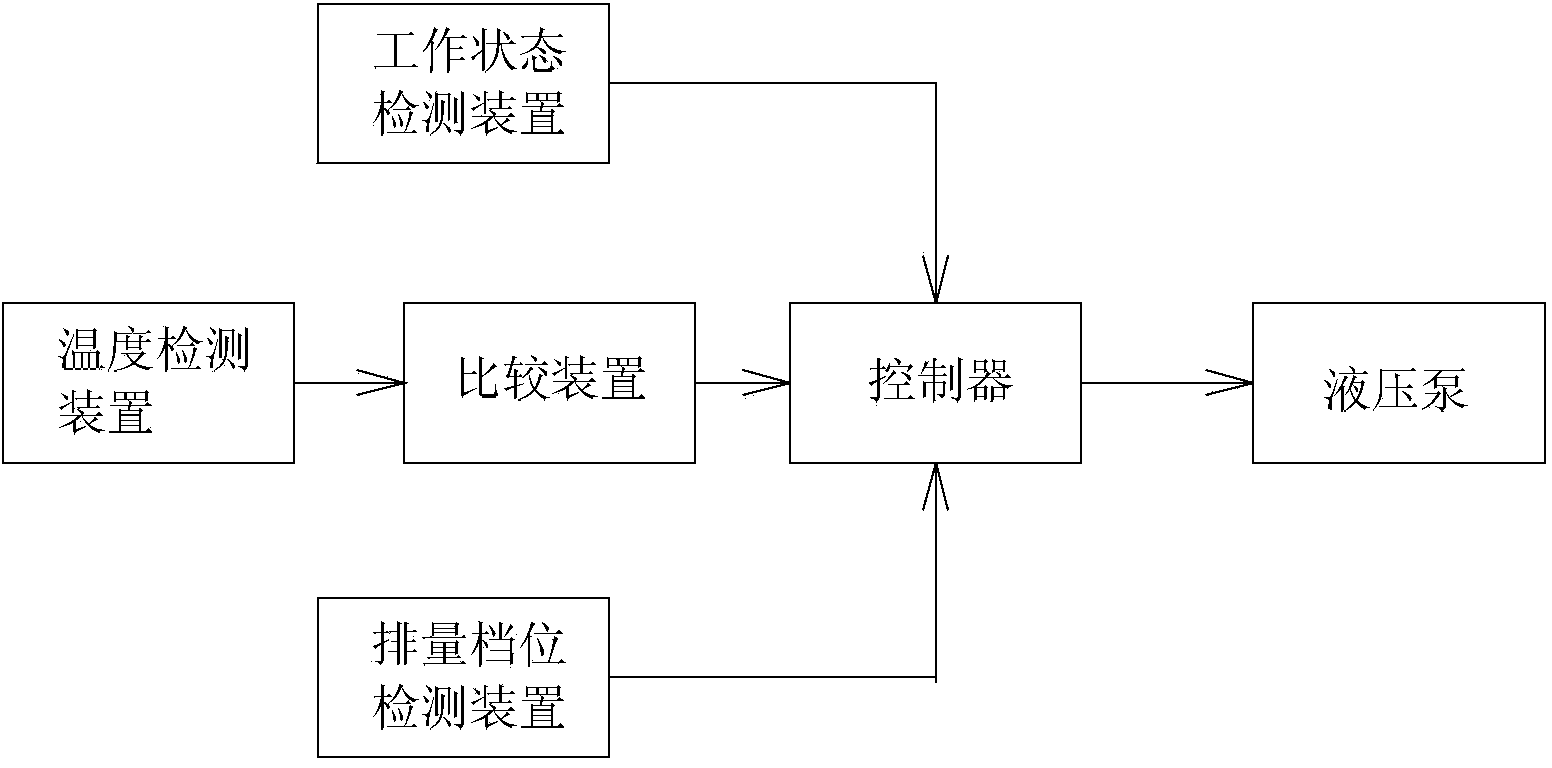

[0026] like figure 1 As shown, according to an embodiment of the present invention, the temperature control method of the pumping hydraulic system includes: dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com