Transmission for a motor vehicle

一种变速器、汽车的技术,应用在车辆变速箱、车辆部件、带有齿的元件等方向,能够解决高费用等问题,达到控制技术简化、成本低、结构的简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

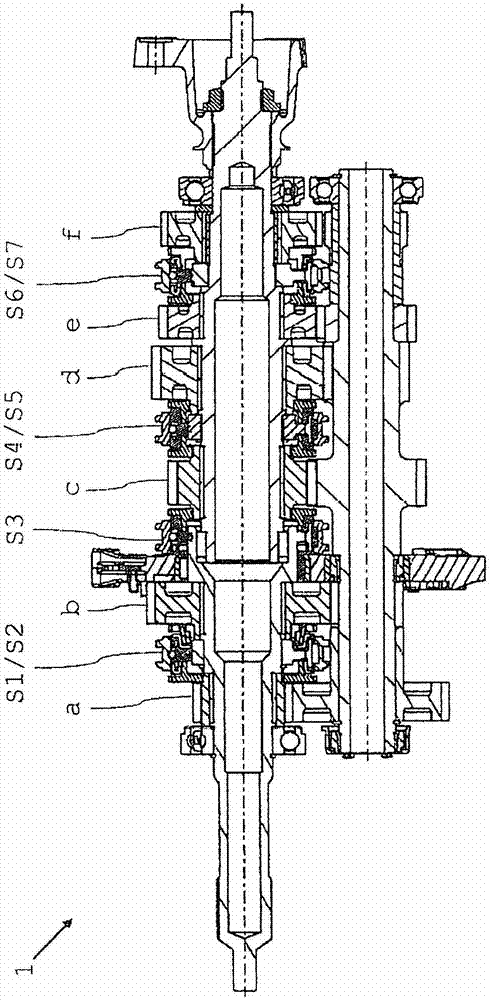

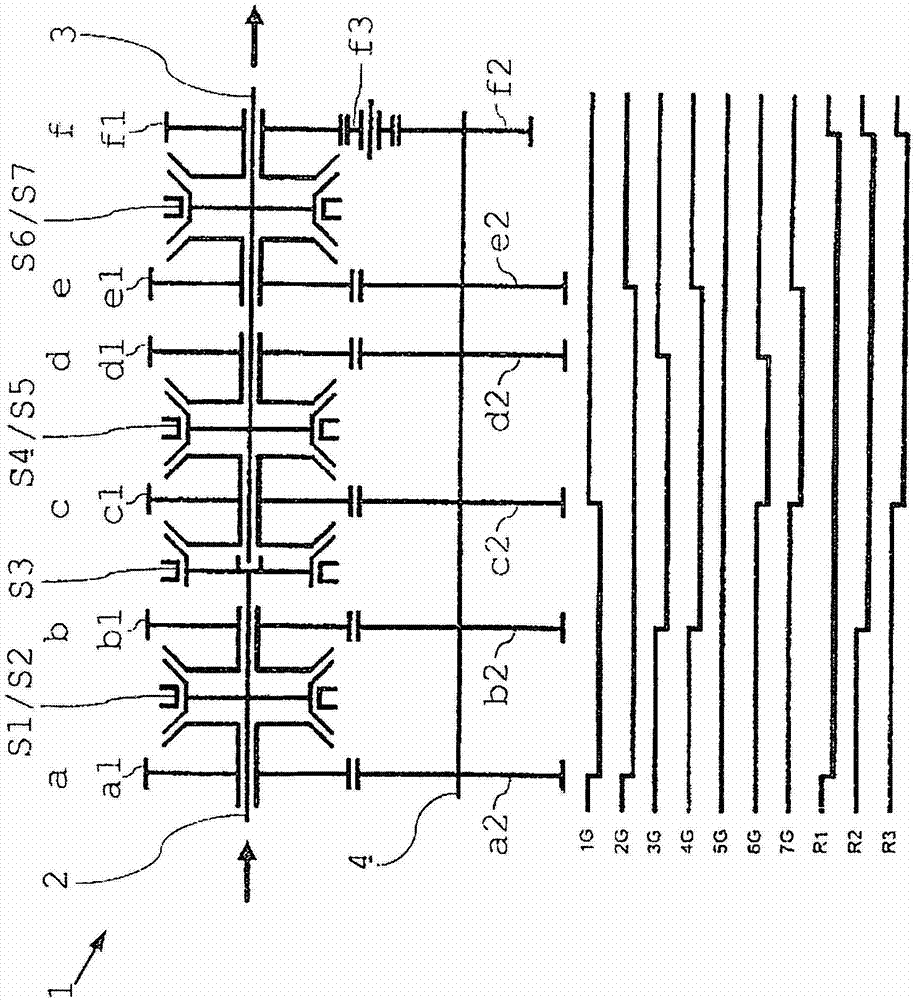

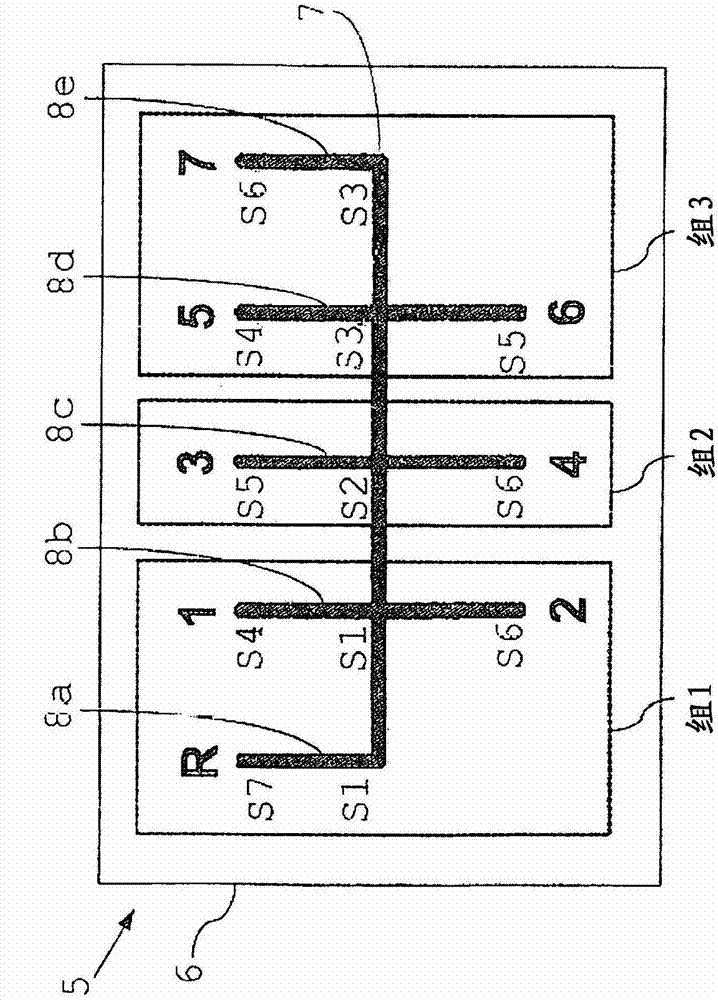

[0039] a press figure 1 The transmission for automobiles has six gear set planes a, b, c, d, e, f and seven gear clutches S1, S2, S3, S4, S5, S6, S7. Depend on figure 2 The transmission structure can be easily seen.

[0040] The transmission 1 is designed as an intermediate shaft transmission comprising a drive-side input shaft 2 , a driven-side output shaft 3 arranged coaxially behind the input shaft, and an intermediate shaft 4 arranged axially parallel to these transmission shafts 2 , 3 .

[0041] The six gear set planes a to f are respectively formed as spur gear pairs a1 / a2, b1 / b2, c1 / c2, d1 / d2, e1 / e2, f1 / f2 in meshing toothing, with the last gear set plane f A steering reversal gear f3 with a rotatable bearing is added in order to enable the respective reverse gears. The spur gear pairs a1 / a2, b1 / b2, c1 / c2, d1 / d2, e1 / e2, f1 / f2 respectively have: idler gears a1, b1, c1, d1, e1, f1, which are rotatably supported on On the input shaft 2 or the output shaft 3 and can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com