Gapless flexible transmission mechanism

A flexible transmission and gapless technology, which is applied in the direction of transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of transmission hysteresis, low transmission efficiency, high manufacturing cost of transmission precision, etc., and achieve large transmission ratio and use Long life, guaranteed transmission accuracy and service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

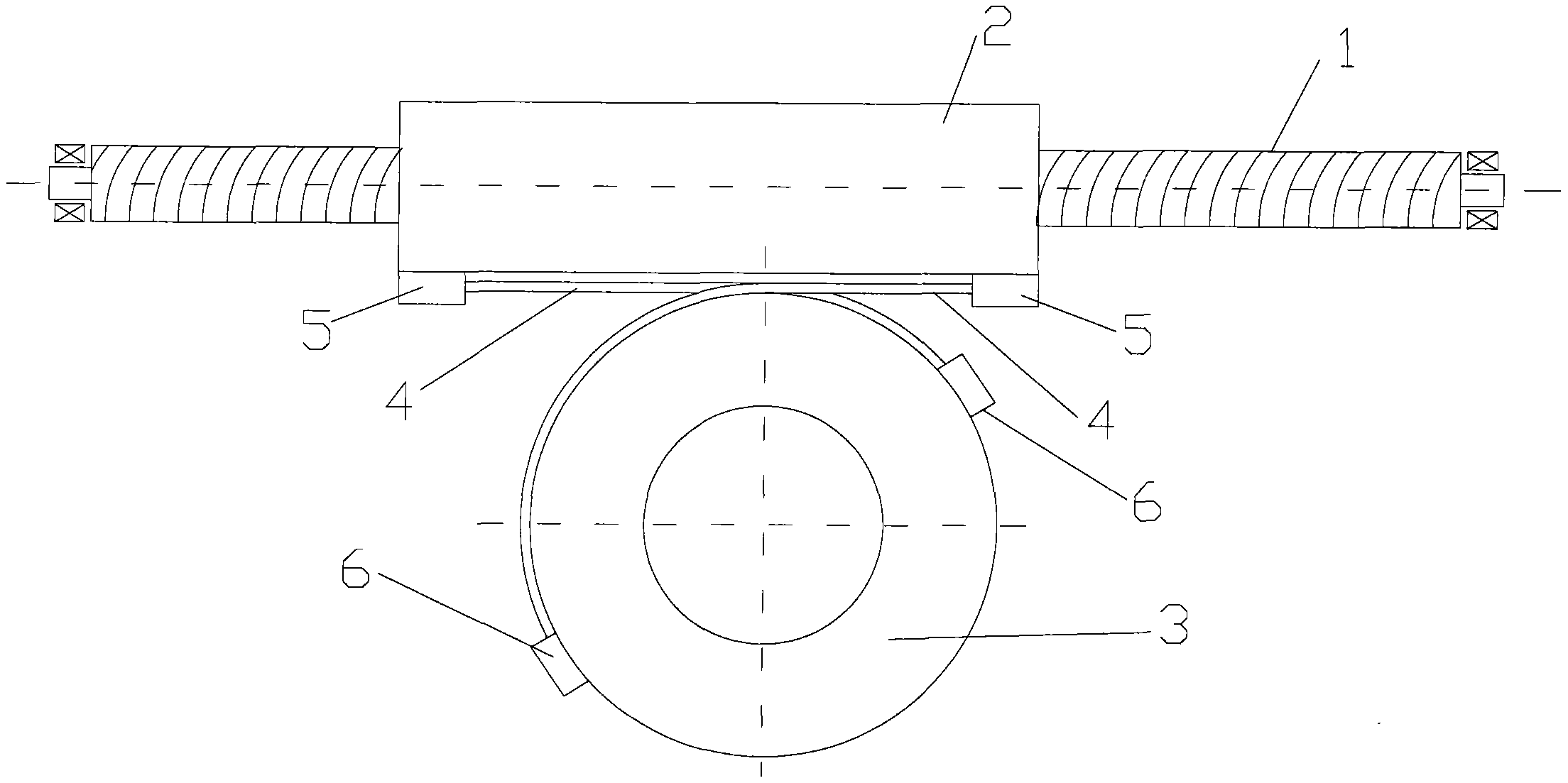

[0030] As shown in the figure, a gapless flexible transmission mechanism is mainly composed of a lead screw 1, a screw nut 2 matched with the lead screw 1, a circular rotation device 3 and several flexible belts 4, and the screw nut 2 is installed on the lead screw 1 , one side and two ends of the nut 2 are respectively provided with a fixed support 5, two pin seats 6 are arranged symmetrically on the circumference of the circumferential rotation device 3, and the flexible belt 4 is a flexible steel belt, which is symmetrically connected to the nut 2 and the circumference Between the rotating device 3, the two ends of the flexible belt 4 are respectively connected to the fixed support 5 of the nut 2 and the pin seat 6 of the circular rotating device 3, and the flexible belt 4 is made of a material that is bendable and has a certain tensile strength , such as flexible steel belts, chains, fiber braided belts and soft steel wire ropes. The straight line formed by the flexible bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com