Vehicle-mounted gas cylinder group trailer type gas station

A technology for gas storage cylinders and gas cylinder groups, which is used in gas/liquid distribution and storage, equipment for loading pressure vessels, and methods for container discharge, etc. Investment, significant technological progress, savings in compression equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

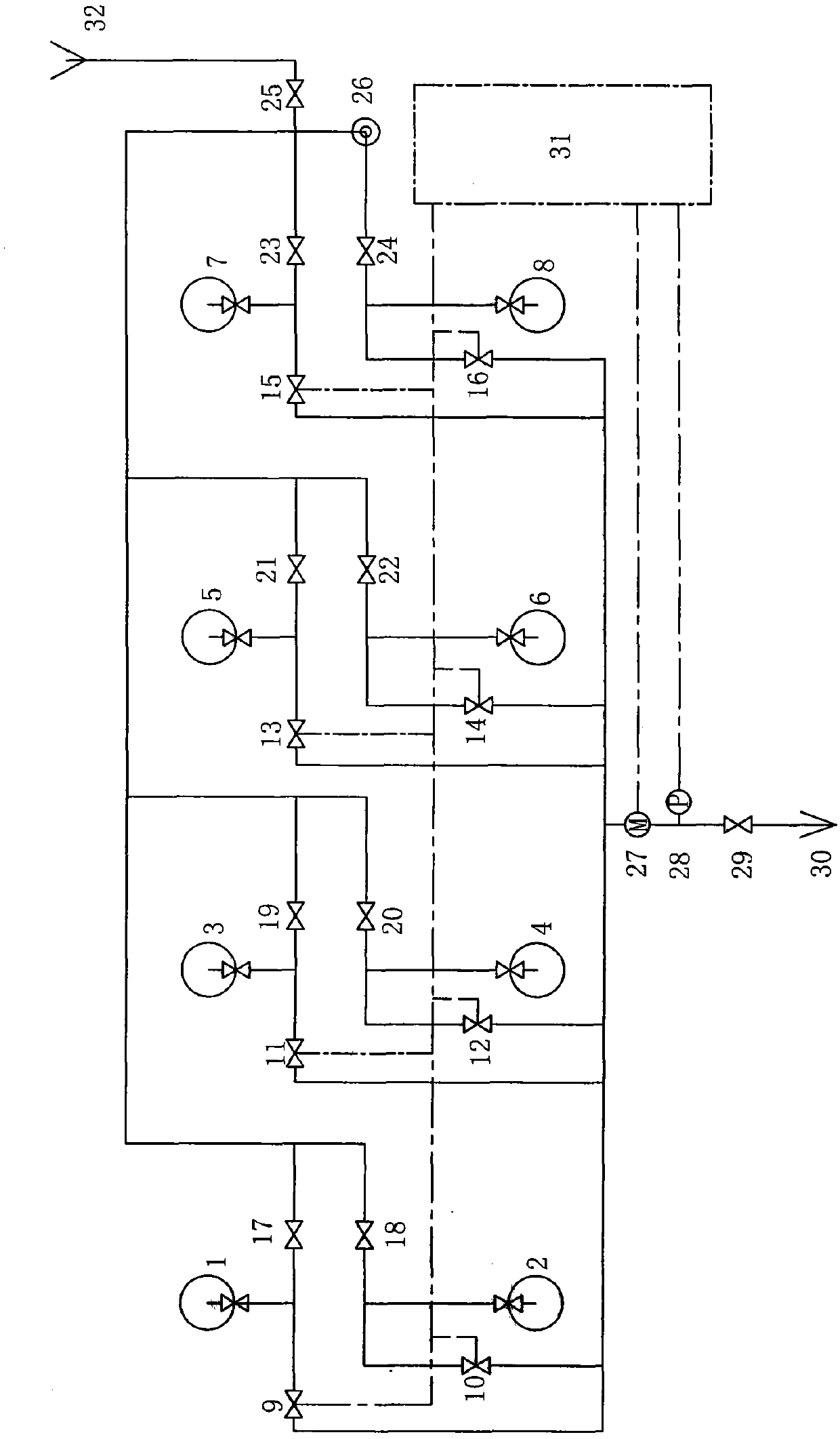

Method used

Image

Examples

Embodiment Construction

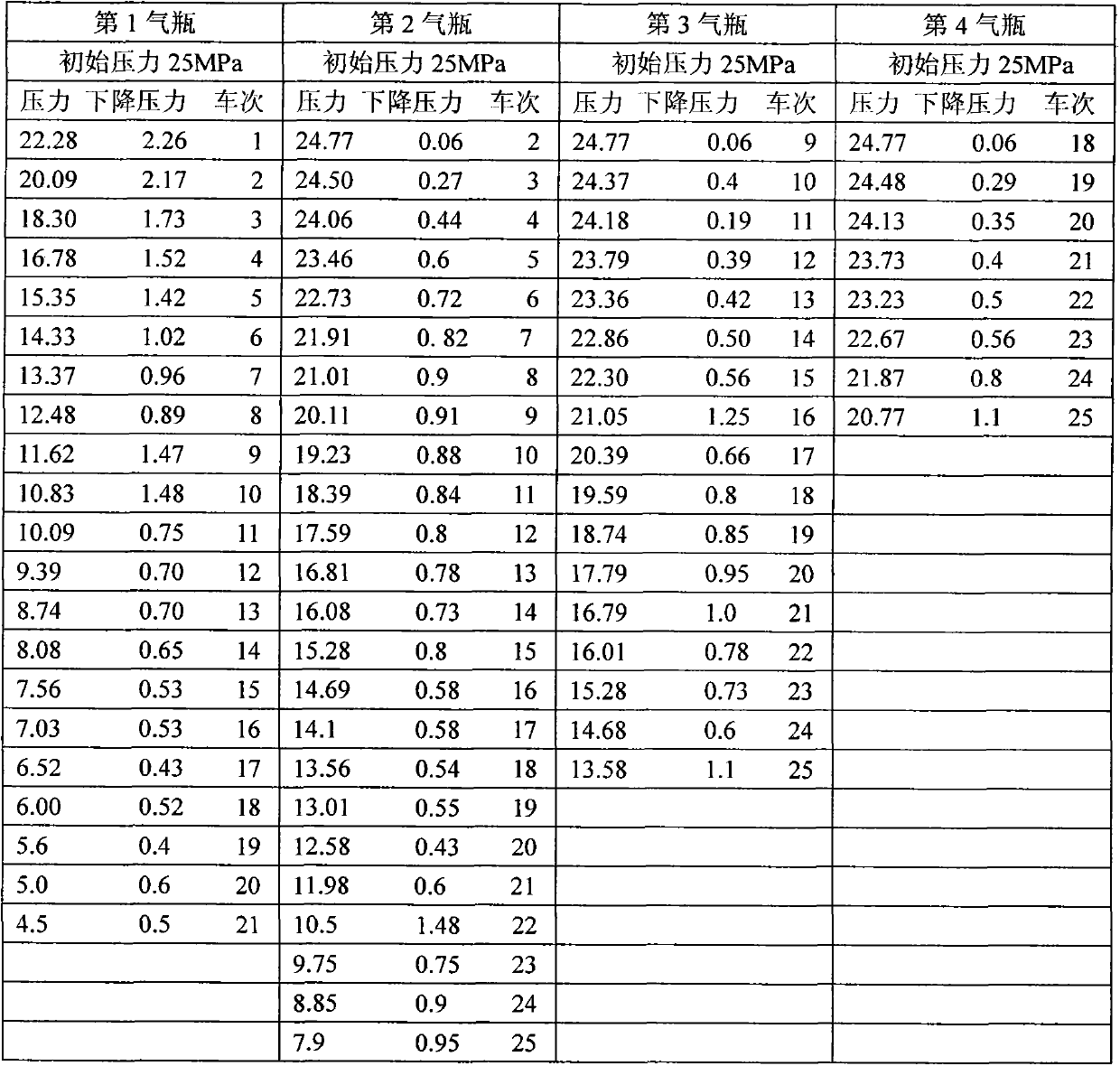

[0044] A vehicle-mounted gas storage cylinder set trailer type gas filling station or a gas storage cylinder set container type gas filling station has a simple filling process, which will not be repeated here. A vehicle-mounted gas storage cylinder group trailer type gas filling station or a gas storage cylinder group container type gas filling station, using the filling port to fill the gas cylinder group with a full pressure, and the full pressure value is greater than that of natural gas or hydrogen The rated pressure value of gas cylinders on fuel vehicles. As long as this condition is met, here is how to use the pressure of the filling port to fill the gas cylinder group to complete the external gas filling, and how to complete the external gas filling without secondary pressurization of the compression equipment. This is the greatest technical advancement of the present invention.

[0045] The full pressure value is greater than the rated pressure of natural gas or hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com