Tunnel type air sterilization energy-saving purifying system

An air disinfection and purification system technology, which is applied in air conditioning systems, air quality improvement, heating methods, etc., can solve the problems of increasing disinfection and purification costs, and achieve the effect of cost reduction and suitable air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

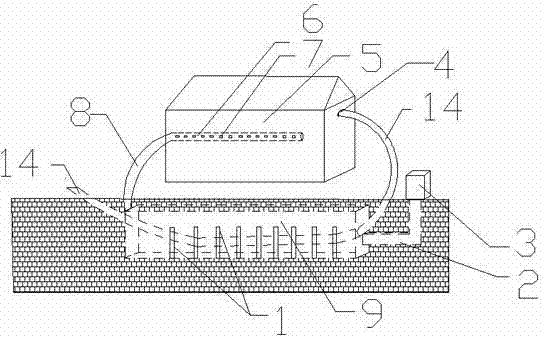

[0014] like figure 1 Shown, a kind of tunnel-type air disinfection energy-saving purification system, including the breeding plant 5, the breeding plant 5 is provided with an air outlet 4, and also includes the tunnel that is arranged directly below the breeding plant 5, the first tunnel that communicates with the tunnel 9 and the breeding plant 5. The air passage duct 8 and the second air passage duct 14 arranged through the tunnel 9 are provided with an air inlet and an air outlet, and a plurality of ultraviolet lamps 1 are arranged in the tunnel 9 . The air inlet of the tunnel is provided with an air filter 3, the air outlet of the tunnel is connected to one end of the air duct 8, and the other end of the air duct 8 is sealed and extended inside the breeding plant 5, and the air duct 8 A plurality of ventilation holes 7 are evenly arranged on the side wall of the air duct 6 inside the breeding workshop 5; The exhaust gas can also be exported externally by an exhaust fan, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com