Rocket composite simulation test device

A test device and composite simulation technology, which is applied in the test of ammunition, ammunition, weapon accessories, etc., can solve problems such as simulation difficulties, and achieve the effects of reliable structure design, convenient operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

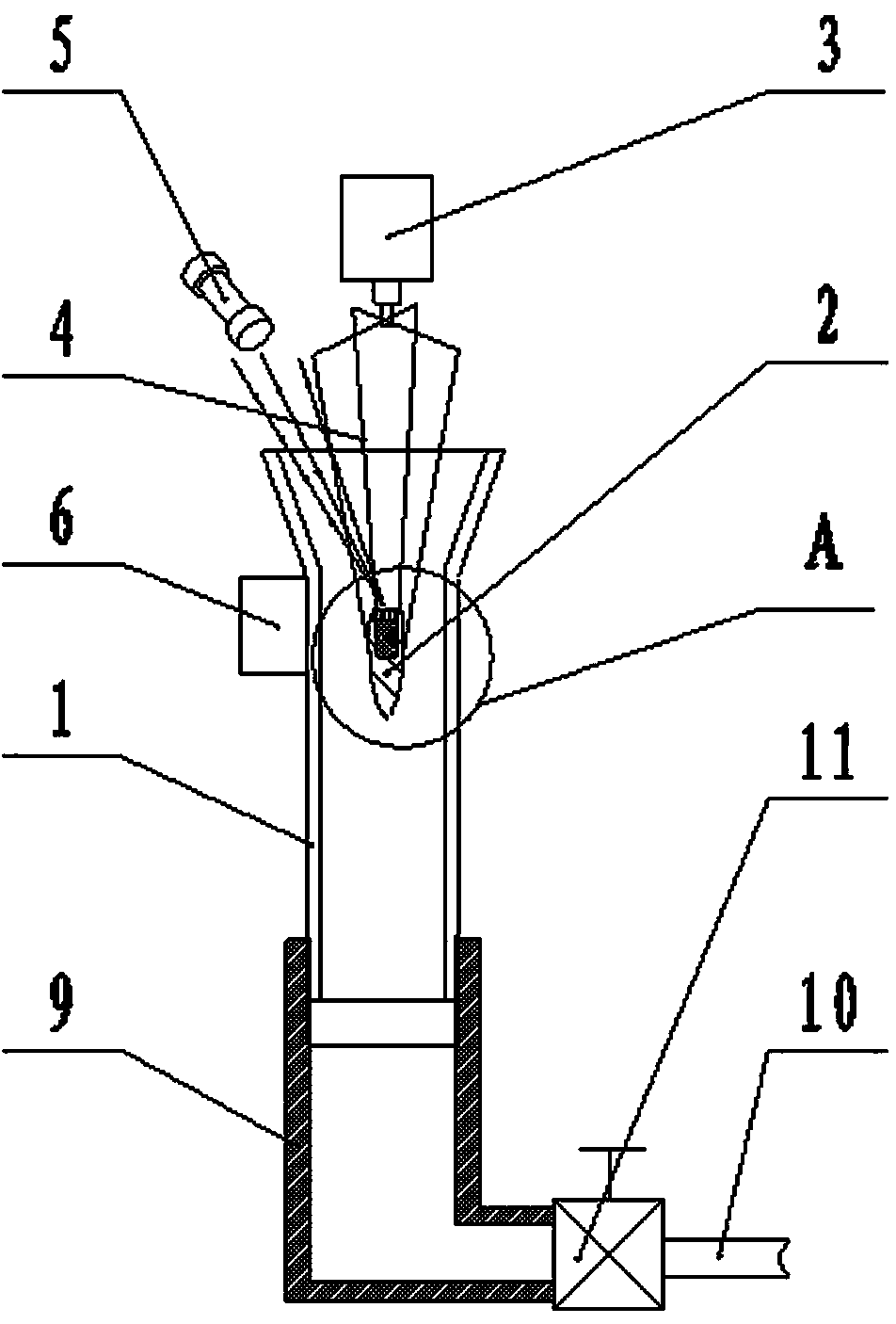

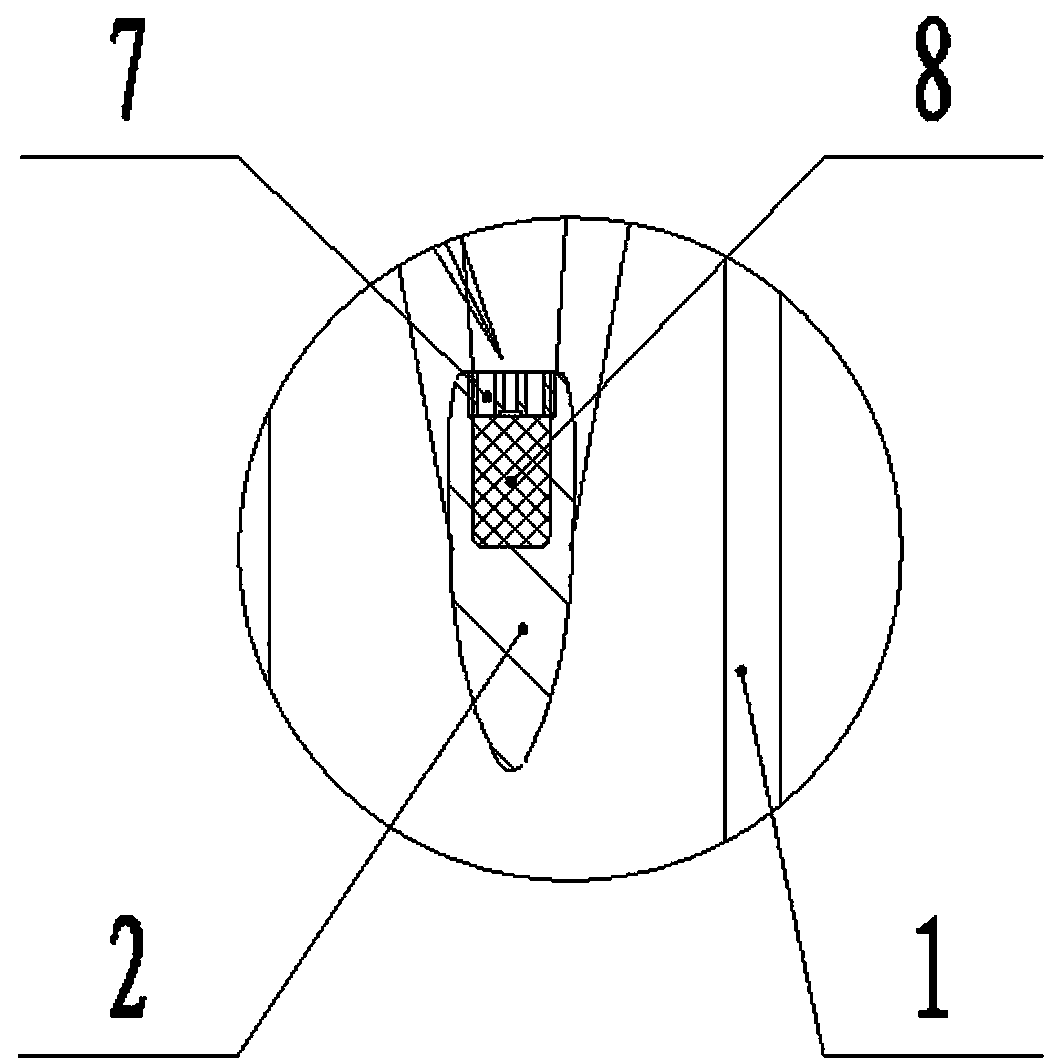

[0015] The compound simulation test device for projectiles and arrows includes a plexiglass air intake pipe 1 with a flared upper end, a plexiglass air intake pipe 1 is provided with a projectile and arrow carrier 2, a high-speed motor 3 is arranged above the projectile and arrow carrier 2, and a high-speed motor 3 The output shaft of the output shaft is connected with the suspension wire 4 that the other end is connected with the missile carrier 2, the high-speed motor 3 is provided with a laser source 5 aimed at the tail end of the missile carrier 2, and the outer wall of the plexiglass air intake duct 1 is provided with a The electromagnet 6 aligned with the horizontal position of the arrow carrier 2, a blind hole is opened in the middle of the tail end of the arrow carrier 2, and dry ice 8 is placed in the blind hole, and a tail plug 7 connected to the blind hole is provided at the end of the blind hole, and the tail plug 7 is opened. There is an exhaust hole, the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com