High-low cycle compound fatigue test high-cycle amplitude measuring equipment and method

A technology of fatigue test and amplitude measurement, which is applied in the direction of measuring device, measurement of ultrasonic/sonic wave/infrasonic wave, testing of mechanical components, etc. It can solve the problems of not being able to measure blade tip amplitude, improve test accuracy, be easy to implement, and have high magnification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

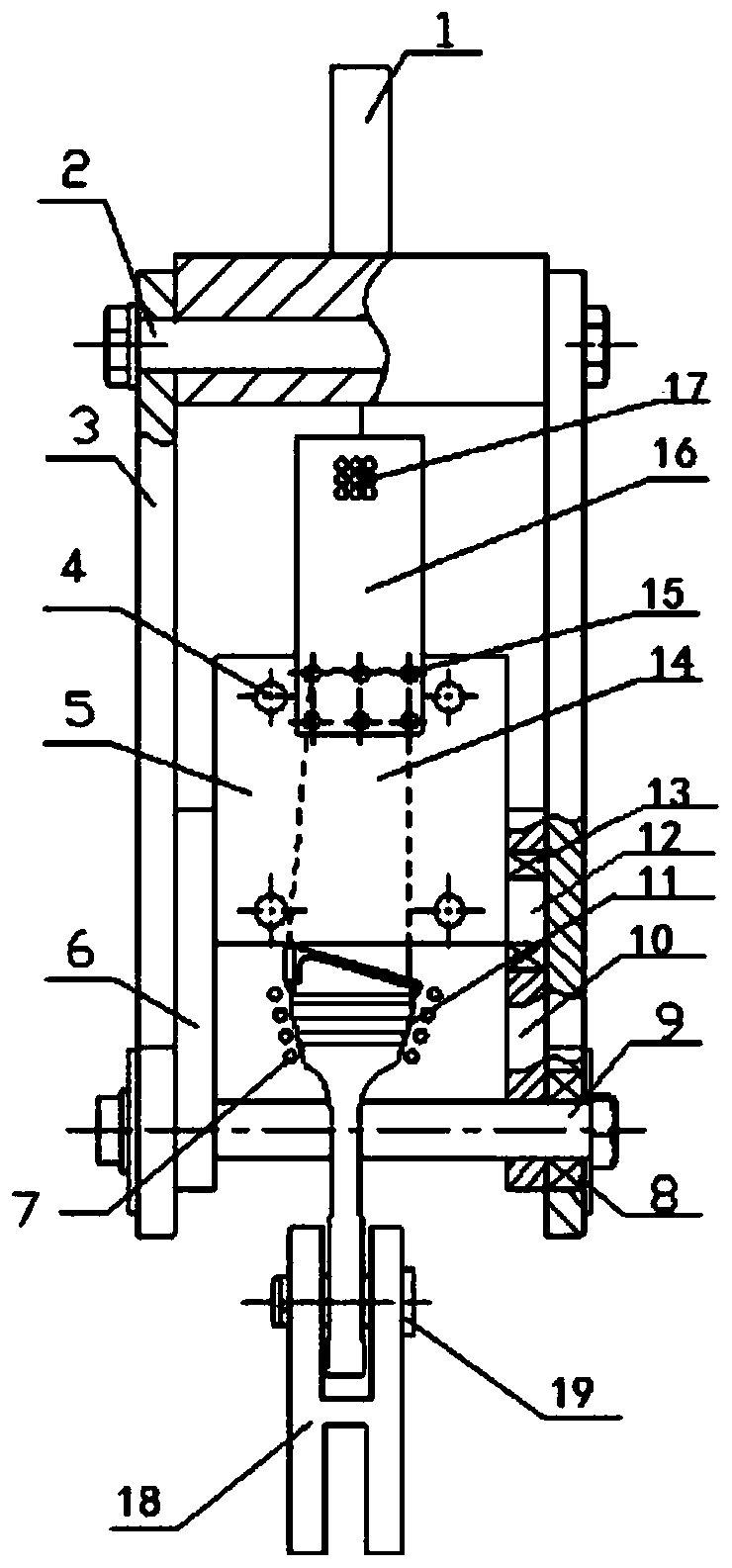

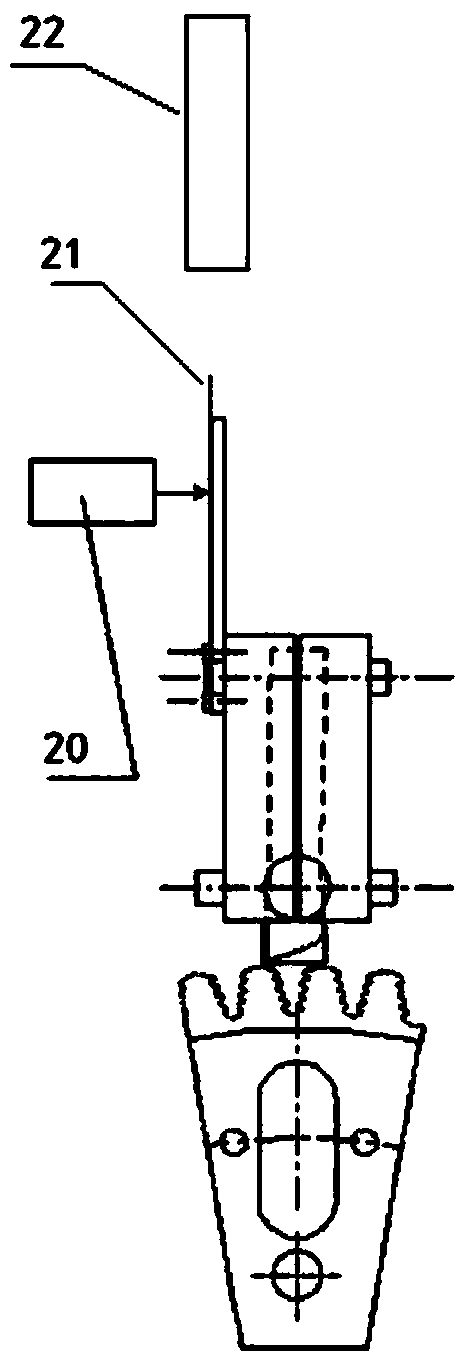

[0017] Such as figure 1 , 2 As shown, the first low-period load reinforcing mechanism 1 is connected to the force-transmitting main tension plate 3 through the first force-transmitting pin 2, and then transmits the force to the blade clamp 5 through the force-transmitting round bar 9 and the second force-transmitting top plate 10, wherein Rolling bearings 13 are installed on the force-bearing lugs 12 of the blade clamp to reduce power consumption, which is the connection relationship of the low-circumference force transmission device. The vibrator 20 simulates the high-cycle load by exciting the excitation point 17 on the high-cycle load transmission plate 16, which is the connection relationship of the high-cycle force transmission device.

[0018] During the measurement, the low cycle load is applied by the first low cycle load applying mechanism 1 and the second low cycle load applying mechanism 18, and then moves to the tongue and groove of the wheel disc 11 through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com