Sampling assembly for detecting pH value of polymerization kettle

A technology for polymerization kettles and components, which is applied to sampling devices and other directions, can solve the problems of inconvenient disassembly and calibration, production impact, electrode short circuit, etc., and achieve the effects of easy disassembly, convenient disassembly, and small maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

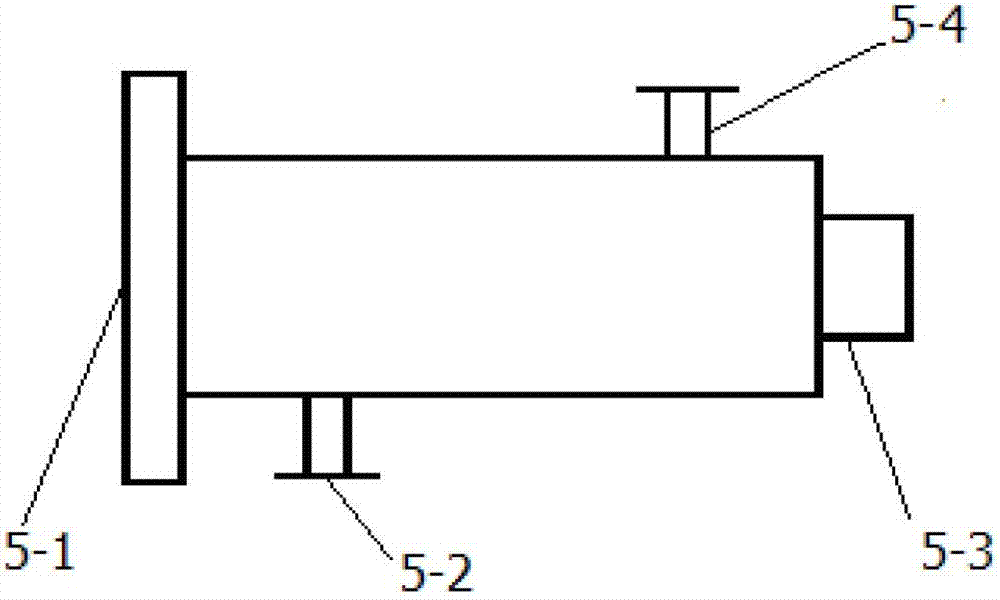

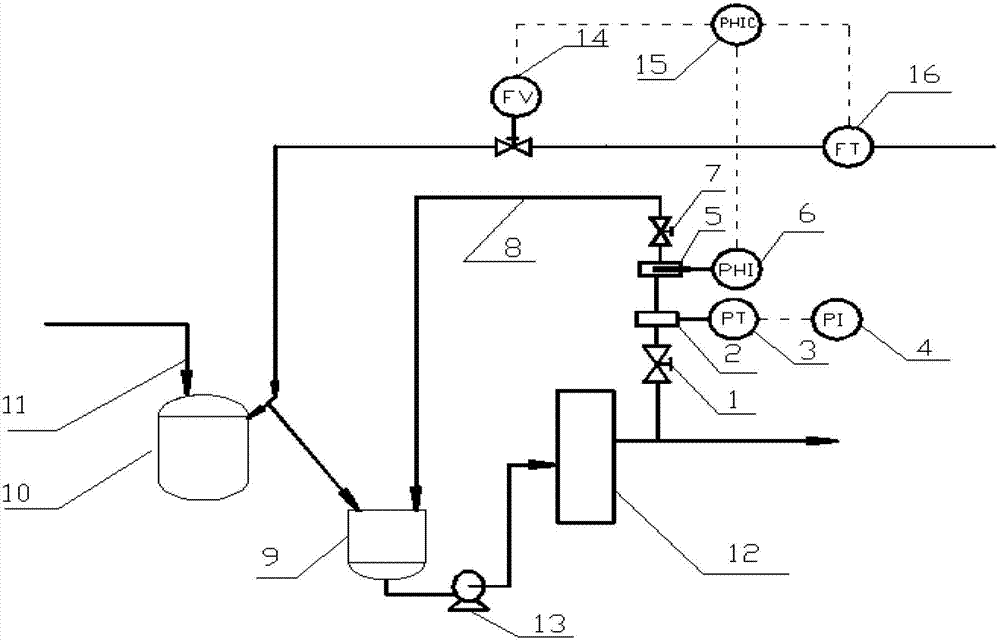

[0038]The pH value detection and sampling assembly of the polymerization kettle according to the present invention is composed of an inlet shut-off valve 1, a pressure sampler 2, a pressure transmitter 3, a flow support 5, a pH transmitter 6, an outlet shut-off valve 7 and a return line 8 The sampling port is arranged at the filter 12 outlets, the inlet shut-off valve 1 is connected with the sampling port, one end of the pressure sampler 2 is connected with the inlet shut-off valve, and the other end is connected with the flow bracket inlet 5-2; the outlet 5-4 of the flow bracket is connected with the The outlet stop valve 7 is connected; one end of the flow support 5 is an open flange 5-1, and the other end is a shrinking sensor installation port 5-3, and the pH transmitter 6 is fixed on the flow support through the installation and fixing end cover of the sensor installation port. 5 above; the outlet of the outlet stop valve 7 is equipped with a return pipeline with a pipe di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com