Experimental method and device for detecting relative viscosity of phenolic resin

A technology of phenolic resin and relative viscosity, which is applied in the field of experimental methods and devices for detecting the relative viscosity of phenolic resin, which can solve problems such as failure of instruments without viscosity of phenolic resin, quality stability control of phenolic resin, etc., to achieve easy operation, avoid loss, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

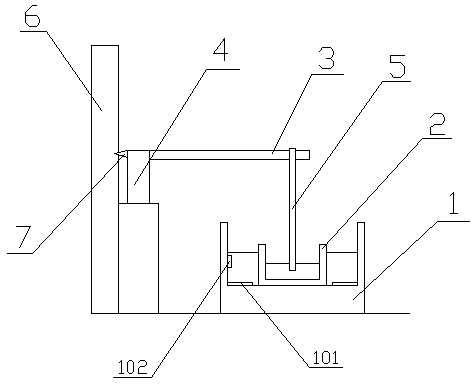

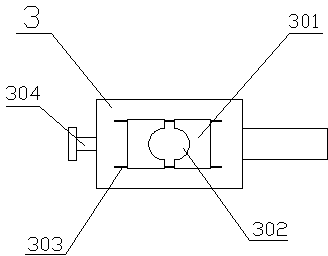

[0021] An experimental method for detecting the relative viscosity of phenolic resin. Take the phenolic resin to be tested, keep it at a specific temperature, immerse one end of a cylindrical stainless steel rod of a specific specification in the phenolic resin to a certain depth, and keep it for a certain period of time until the resin level reaches a certain depth. After leveling, slowly lift the stainless steel rod vertically at a certain rate to separate from the phenolic resin. As the phenolic resin adheres to the surface of the stainless steel rod, a resin tape will be pulled out as the stainless steel rod is lifted. Record the break of the resin tape The lifting height of the stainless steel rod is used to evaluate the relative viscosity of the detected phenolic resin.

[0022] The entire device and detection need to be performed at a certain temperature, and the determination of the temperature needs to refer to the actual temperature of the season and the work site.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com