3D-printing-based method and device for making three-dimensional luminous character

A 3D printing, luminous character technology, applied in display devices, illuminated markers, instruments, etc., can solve the problems of insufficiency, low quality of three-dimensional characters, cumbersome procedures, etc., to avoid manpower, ensure internal compactness, improve The effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

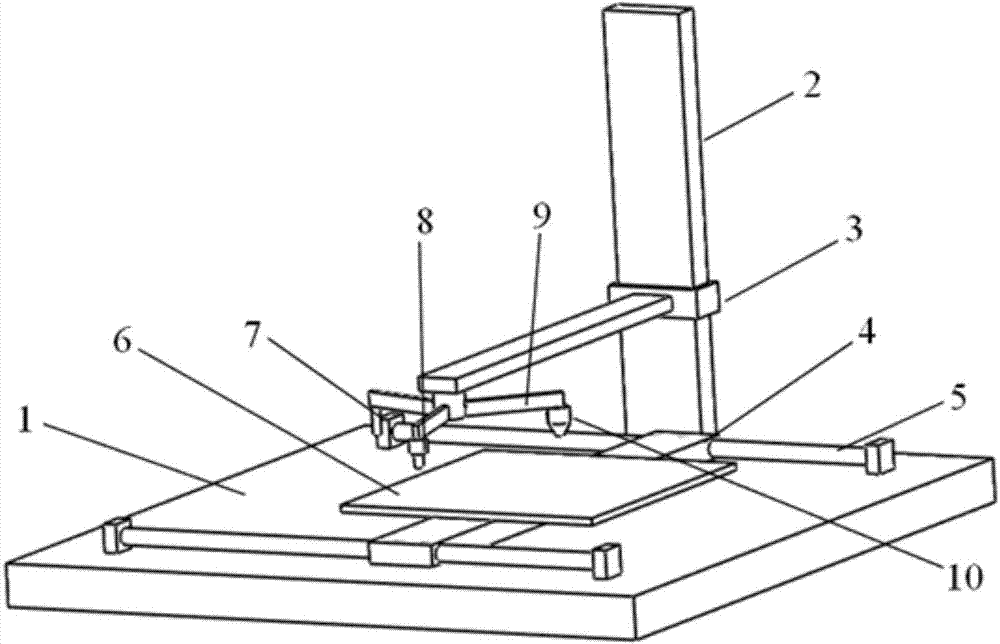

[0042] Such as figure 1 As shown, a device for making three-dimensional luminous characters based on 3D printing, including: a base 1, a Z-axis column 2, a Z-axis beam 3, a Y-axis power mechanism 4, an X-axis guide rod 5, a processing table 6, and an infrared irradiation head 7 , 8 milling cutters, 9 tool holders, 10 three-dimensional printing nozzles.

[0043]The Y-axis power mechanism 4 is used to drive the processing table 6 to move in the Y-axis direction; the Y-axis power mechanism 4 can adopt a motor and a motor-driven synchronous belt and synchronous wheel structure; the Y-axis power mechanism 4 and the processing table 6 pass through as a whole The guide rail slider is installed on the X-axis guide rod 5 on the base 1; under the action of the X-axis power mechanism, the Y-axis power mechanism 4 and the processing table 6 can move in the X-axis direction along the X-axis guide rod 5; the X-axis power Mechanism can also choose the synchronous wheel and synchronous belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com