Underwater monitoring method and device of hydraulic gripping beam

A monitoring device and hydraulic technology, applied in water conservancy engineering, marine engineering, construction and other directions, can solve the problem that signal reliability and anti-interference cannot be reliably guaranteed, and cannot observe the movement process of hydraulic grabbing beam axis shifting in real time and dynamically. , signal device damage and other problems, to achieve the effect of enhancing anti-interference and accuracy, saving operating costs and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

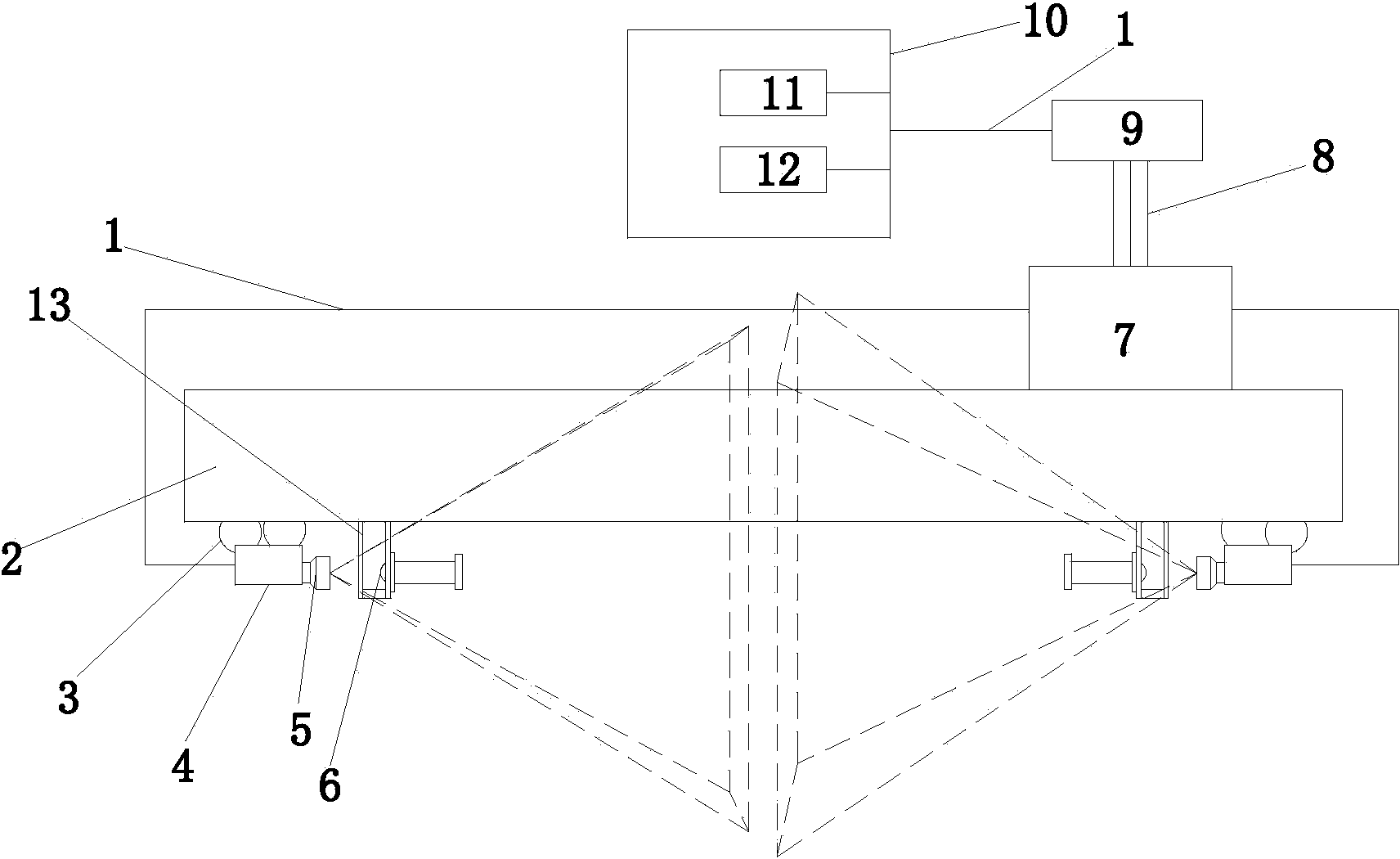

[0025] Example. The hydraulic grab beam underwater monitoring method is characterized in that: a high-definition camera is installed on the hydraulic grab beam, and the process of wearing and out of stock of the hydraulic grab beam is observed through the high-definition camera, thereby improving the safety of the hydraulic grab beam operation and ensuring early detection of hydraulic Problems during the operation of metal structure products should be dealt with in a timely manner to reduce losses.

[0026] It is better to install the high-definition camera on the hydraulic grabbing beam through a fixed bracket, and install a stainless steel cover on the high-definition camera for waterproofing. The high-definition camera is connected to the LCD monitor in the monitoring room through the signal cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com