An electromechanical-electroacoustic transducer with low thickness and high travel range and relevant manufacturing method

A technology of electro-acoustic transducers and transducers, applied in the direction of sensors, electrical components, sensor parts, etc., can solve the problems that are not easy to realize, irrelevant to the external diameter, and the total thickness cannot reach the stroke range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Referring to the above drawings, there is disclosed the transducer of the present invention. Hereinafter, the terms "below, above, horizontal and vertical" refer to configurations in the drawings.

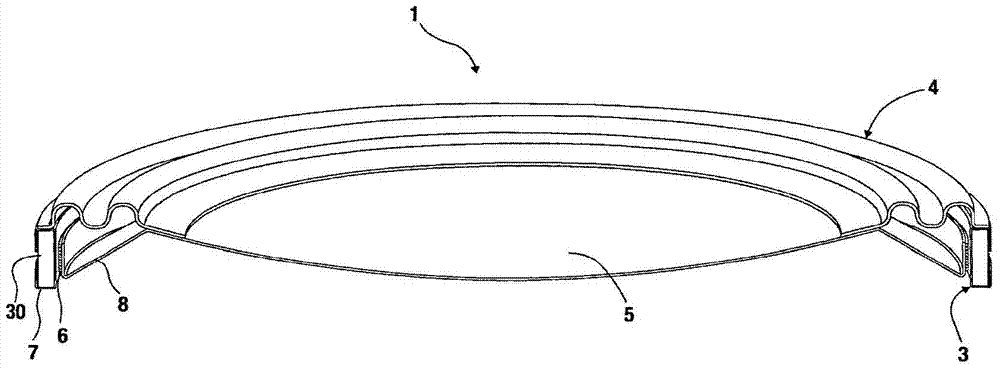

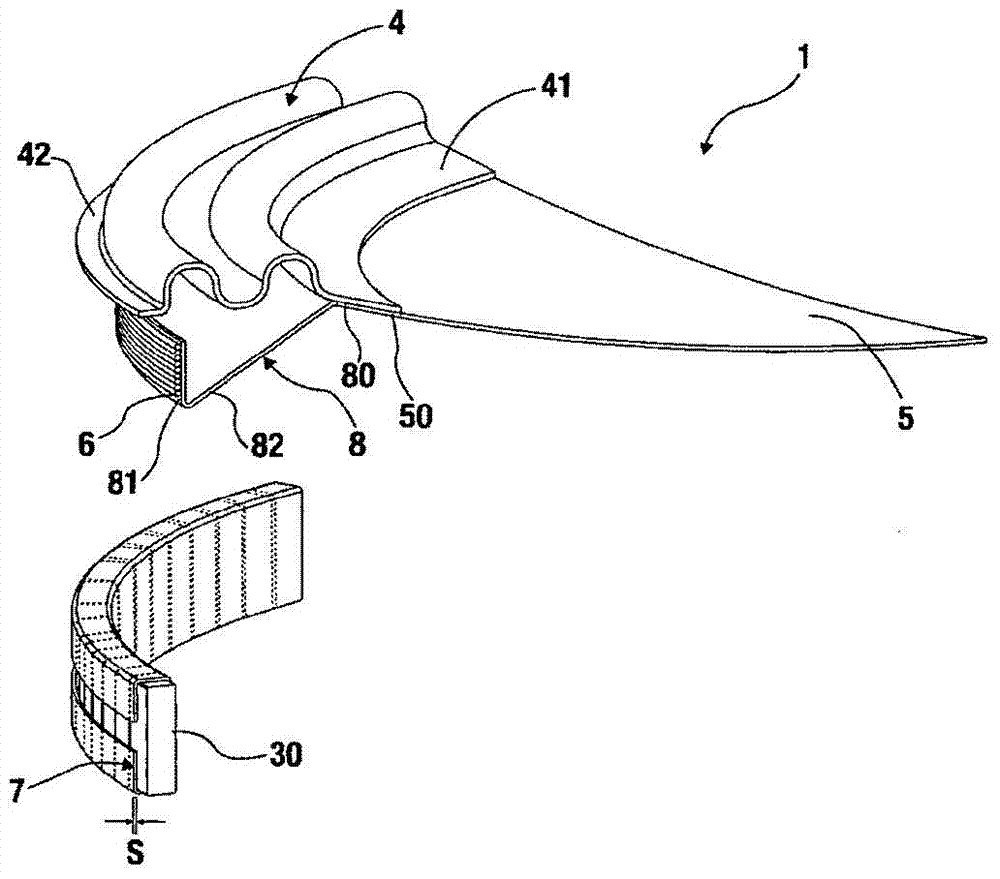

[0045] refer to Figure 1 to Figure 6 , discloses a first embodiment of a transducer, generally indicated by reference numeral 1 .

[0046] The transducer 1 includes: a magnetic assembly 3; an elastic suspension 4 connected to the magnetic assembly 3; a sound membrane 5 connected to the elastic suspension 4; and a coil 6 supported by a support 8, the support The component is connected with the sound membrane 5 so as to move relative to the magnetic assembly 3 .

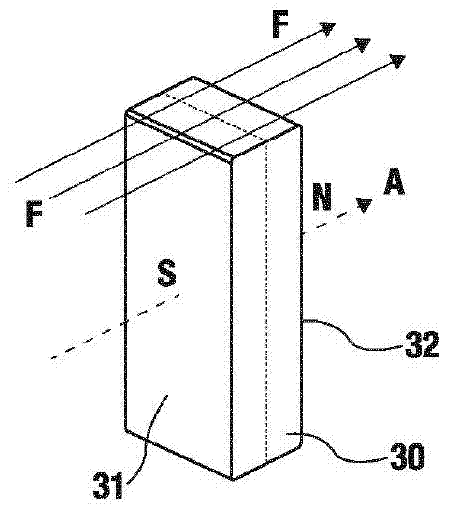

[0047] refer to figure 2 , the magnetic assembly 3 includes a plurality of magnets 30 which are accommodated and supported by the support structure 7 .

[0048] refer to Figure 2A As shown, each magnet 30 has two opposing sides 31, 32 with a south magnetic pole S and a north magnetic pole N therein. Thus, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com