Automatic fixture for machining large parts of rail vehicles

A technology for automated industrial and rail vehicles, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of low production efficiency and long auxiliary time, and achieve the effect of improving production efficiency and reducing auxiliary time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

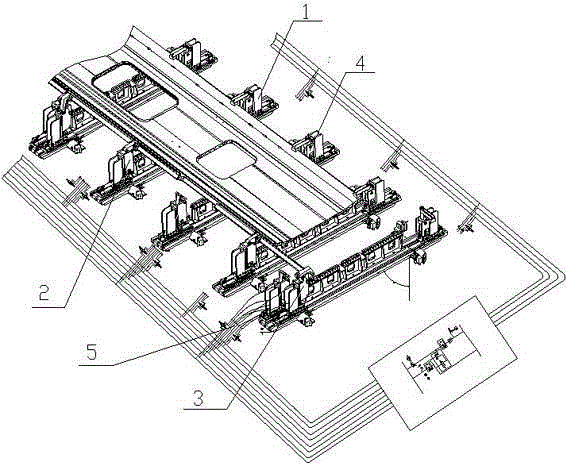

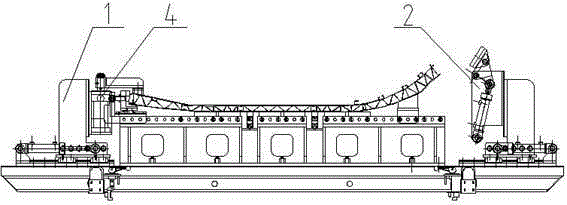

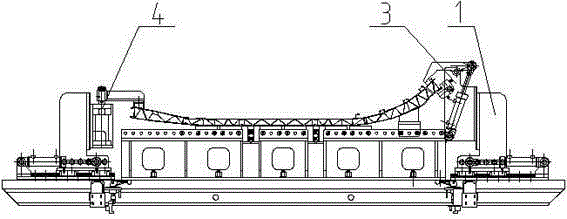

[0023] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the automatic side wall processing tooling of the present invention includes a sliding base 1, an acute angle pressing mechanism 2, an obtuse angle pressing mechanism 3, a vertical rotary pressing mechanism 4, and a hydraulic drive system 5, and the sliding base is connected with a multi-angle pressing mechanism , The hydraulic drive system controls the expansion and contraction of the sliding base, thereby controlling the multi-angle pressing mechanism to move away from or approach the workpiece. At the same time, the hydraulic drive system also controls the rotation angle of the multi-angle pressing mechanism, so as to realize the pressing of different workpieces. The hydraulic drive system adopts two-way solenoid valve 501 and PLC integrated control, and different control programs are compiled according to different workpieces to be processed, and different hydraulic cylinders are driven to feed in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com