Continuous variable cross-section car front longitudinal beam and preparation method thereof

A front longitudinal beam and variable section technology, which is applied to vehicle components, substructures, transportation and packaging, etc., can solve the problems of difficult control of the overall forming process, unfavorable deformation and energy absorption of the front of the longitudinal beam, and high quality control requirements. Realize the effects of light weight, high collision energy absorption performance, and reasonable thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

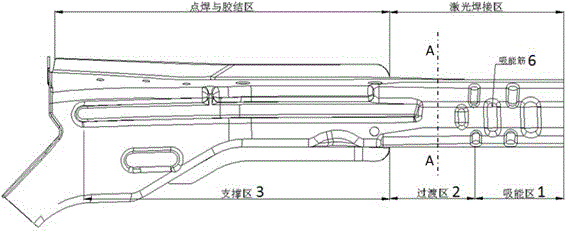

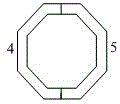

[0027] as attached figure 1 And attached figure 2 As shown, the front side beam of the automobile according to the present invention as a whole includes an inner panel 4 and an outer panel 5 with approximately symmetrical structures made of the same material (the inner and outer panels refer to the inside and outside of the vehicle body), and the inner panel 4 and the outer panel 5 are The longitudinal extension direction of the front longitudinal beam is connected with each other to form a closed hollow cavity structure. Any cross section of the front longitudinal beam is roughly an octagonal structure, especially any cross section of the laser welding area is an octag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com