Sawtooth hanging piece stand column packing device and method for constructing sawtooth hanging piece stand column packing device

A construction method and pendant technology, applied in building components, floors, sound insulation, etc., can solve the problems of inability to adjust the pendant, poor keel stability, large thickness of the finished surface, etc., achieve good decorative effect, good overall rigidity, overcome flexibility and increase big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

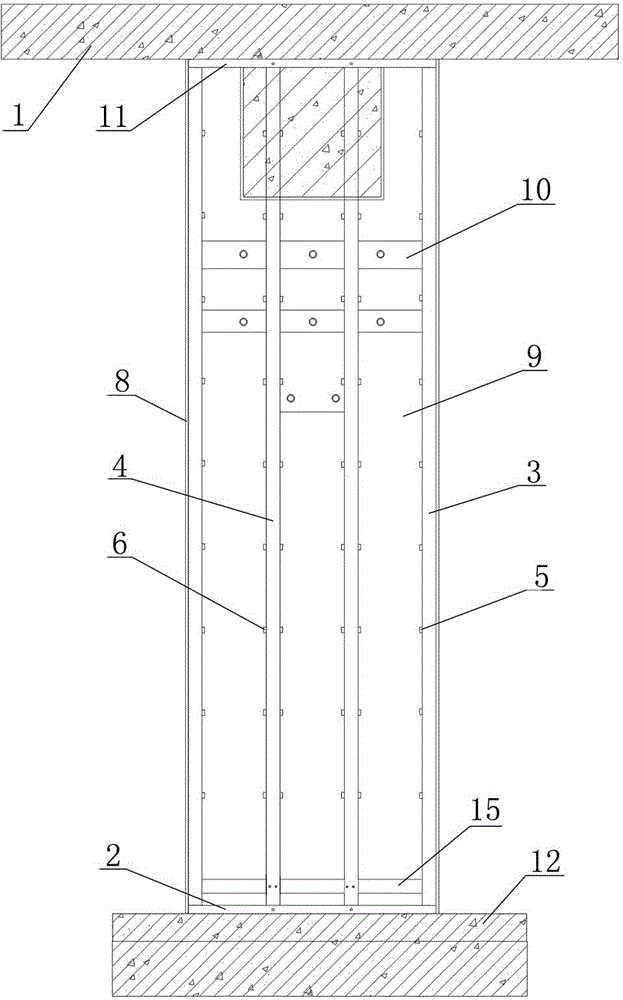

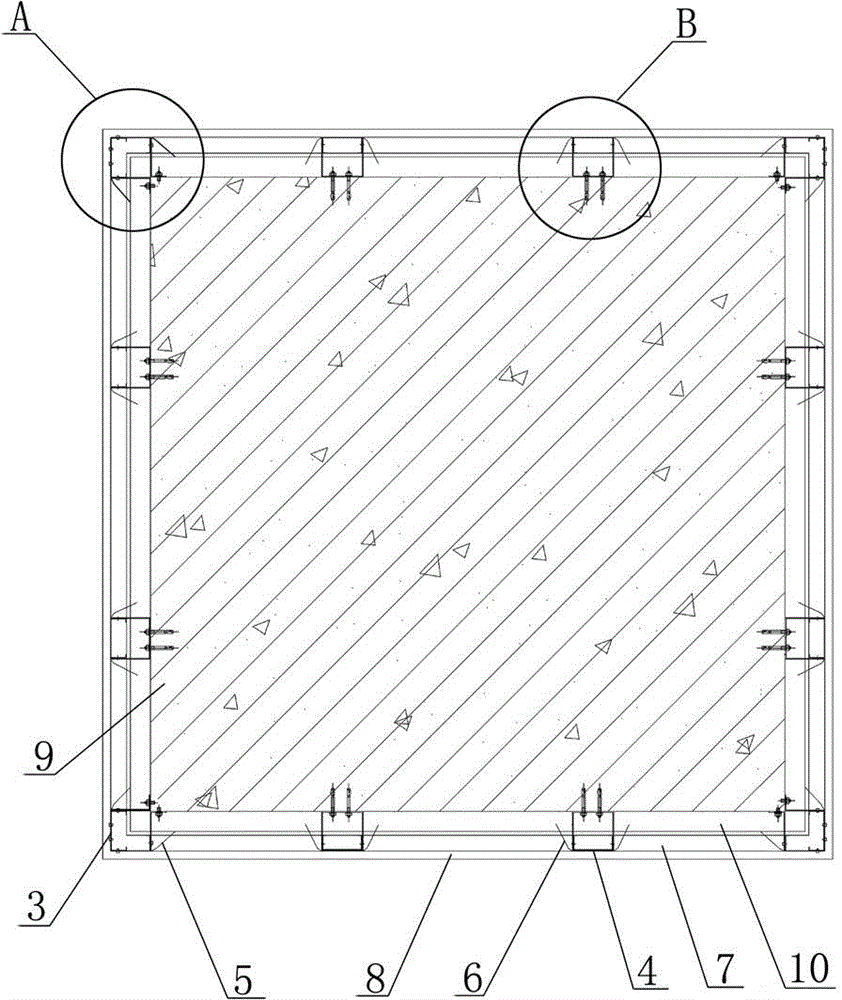

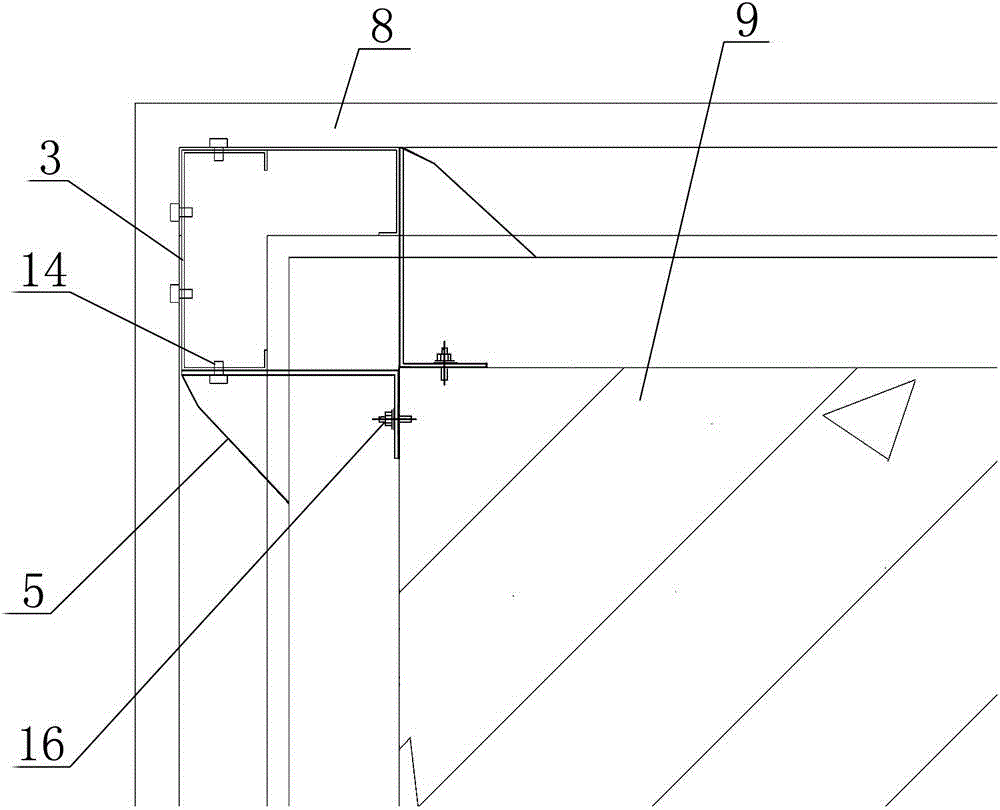

[0052] see example Figures 1 to 7 As shown, this sawtooth pendant column encapsulation device, the cross section of the structural column 9 is rectangular, the surface of the structural column 9 is fixed with a reinforcing steel plate 10 by bolts, the device includes a sky keel 1, a ground keel 2, a frame keel 3, a frame The sawtooth pendant 5 , the vertical keel 4 , the vertical keel sawtooth pendant 6 , the sound insulation filling material 7 and the cover panel 8 .

[0053] The sky keel 1, the ground keel 2, the frame keel 3 and the vertical keel 4 all have a spacing greater than the thickness of the reinforced steel plate 10 between the structural column 9; the sky keel 1 is fixed with the reinforced concrete floor 11 on the top of the structural column, The ground keel 2 is fixed with the ground concrete cushion 12 at the bottom of the structural column, the vertical keel 4 and the frame keel 3 are connected up and down between the sky keel 1 and the ground keel 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com