Damping device for transport of equipment sensitive to vibration

A vibration damping device and shock absorber technology, which is applied in the direction of non-rotational vibration suppression, etc., can solve the problems of not being able to meet the vibration protection requirements of vibration-sensitive equipment, not easy to delay transportation time, and high cost of vibration-absorbing trucks, so as to shorten the appointment time, Guarantee the cost and schedule requirements, and reduce the effect of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

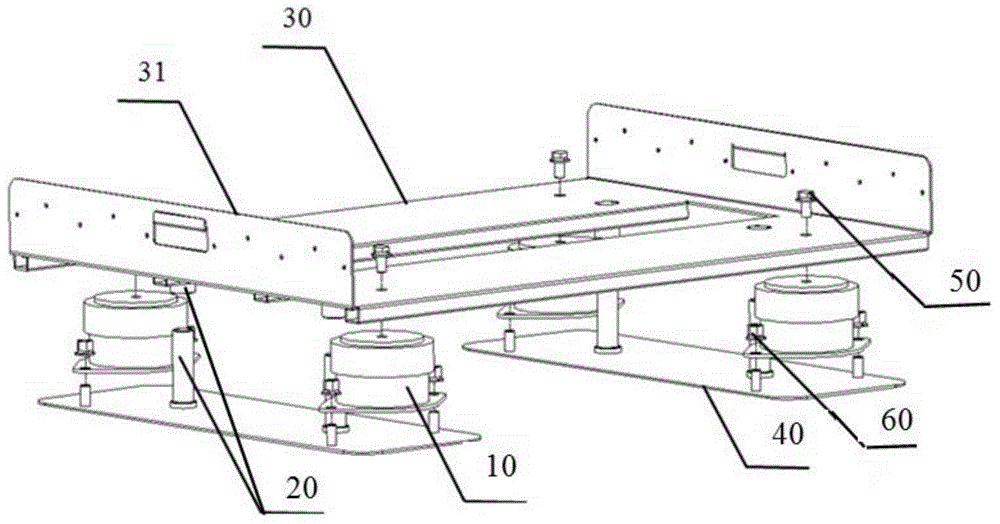

[0016] Such as figure 1 As shown, the damping device in the embodiment includes a damper (10), a positioning and guiding mechanism (20), a damper mounting plate (30) and a damper fixing plate (40). The shock absorber (10) is a spring damping shock absorber. The spring damping shock absorber is small in size and long in life. Its damping effect can absorb part of the energy of the vibration and convert the high frequency vibration that causes damage to the vibration sensitive equipment into an unaffected The low-frequency vibration of equipment performance, after several vibration cycles, the energy is completely absorbed by the spring damping shock absorber, so as to achieve the effect of vibration reduction. The shock absorber (10) is fixedly connected to the shock absorber fixing plate (40) throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com