Motor stator core thickness detection device

A detection device and a technology for iron core thickness, applied in the direction of mechanical thickness measurement, etc., can solve problems such as low detection efficiency, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

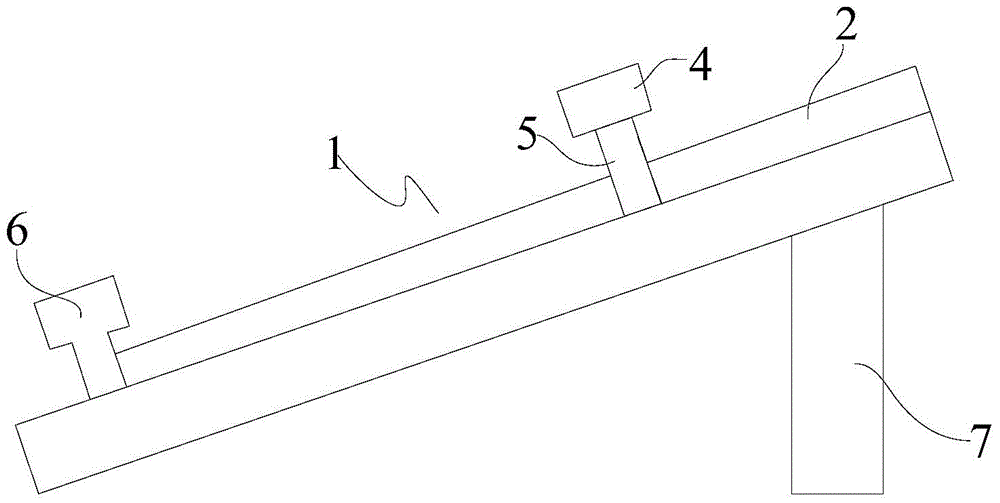

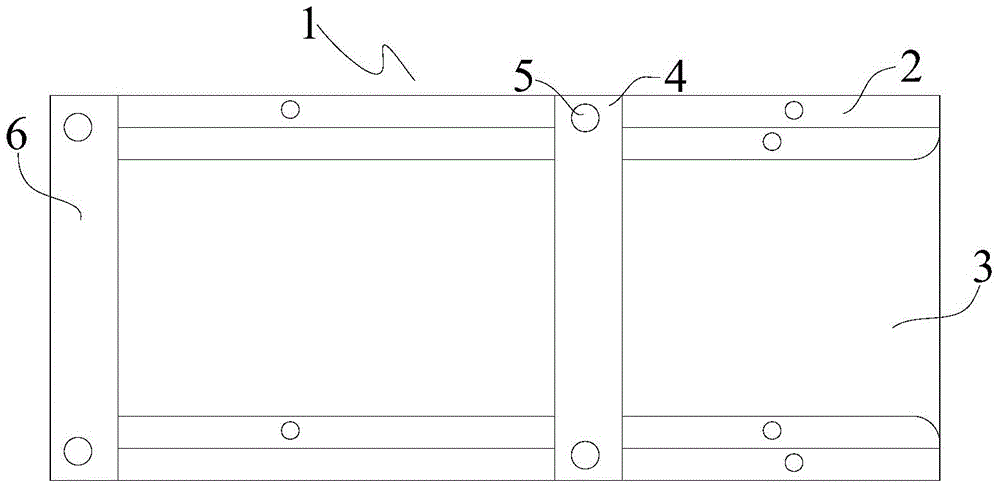

[0019] Embodiment: A motor stator core thickness detection device

[0020] See attached figure 1 And attached figure 2 As shown, a motor stator core thickness detection device, the detection device includes an obliquely arranged chute 1, the chute 1 is composed of a groove wall 2 and a groove bottom 3. The inclined setting of the chute 1 is equivalent to the horizon, that is, the setting of the chute 1 can make the motor stator core slide down along the groove bottom 2 of the chute 1 under the action of its own gravity. Therefore there are two ways to make the chute 1 inclined. One is that the chute 1 itself is flat. When in use, the chute 1 is placed obliquely so that it has a certain angle with respect to the horizon. Another kind is to establish support column 7 at one end of chute 1, utilize the setting of support column 7 to make the groove bottom 3 of chute 1 one end high, one end low, of course high and low also are relative to the horizon.

[0021] A height-limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com