Metal product electroplating equipment

A technology for electroplating equipment and metal products, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of enlargement, affecting the quality of metal products, uneven thickness of the coating on the surface of the parts to be plated, etc., to improve quality and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

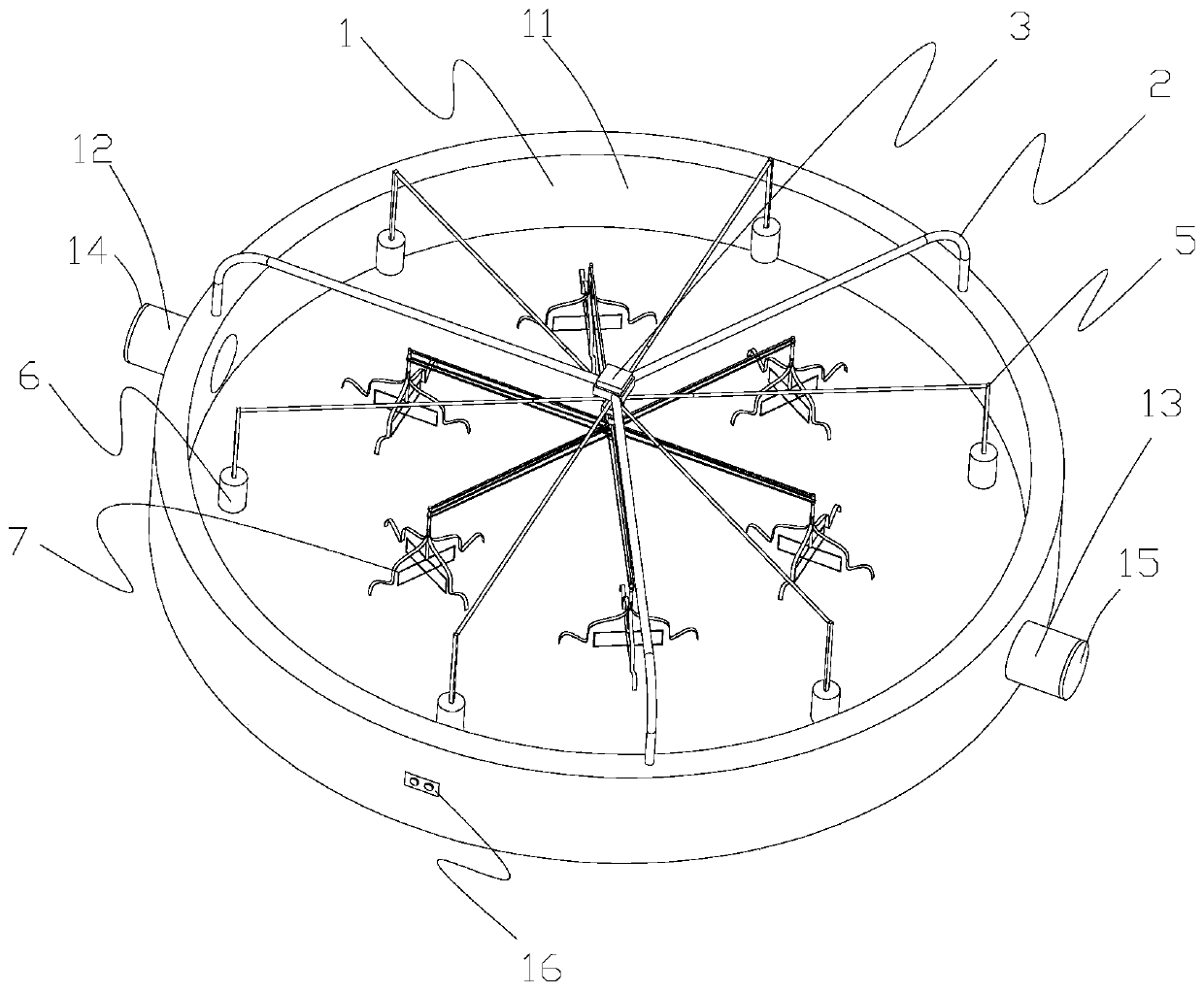

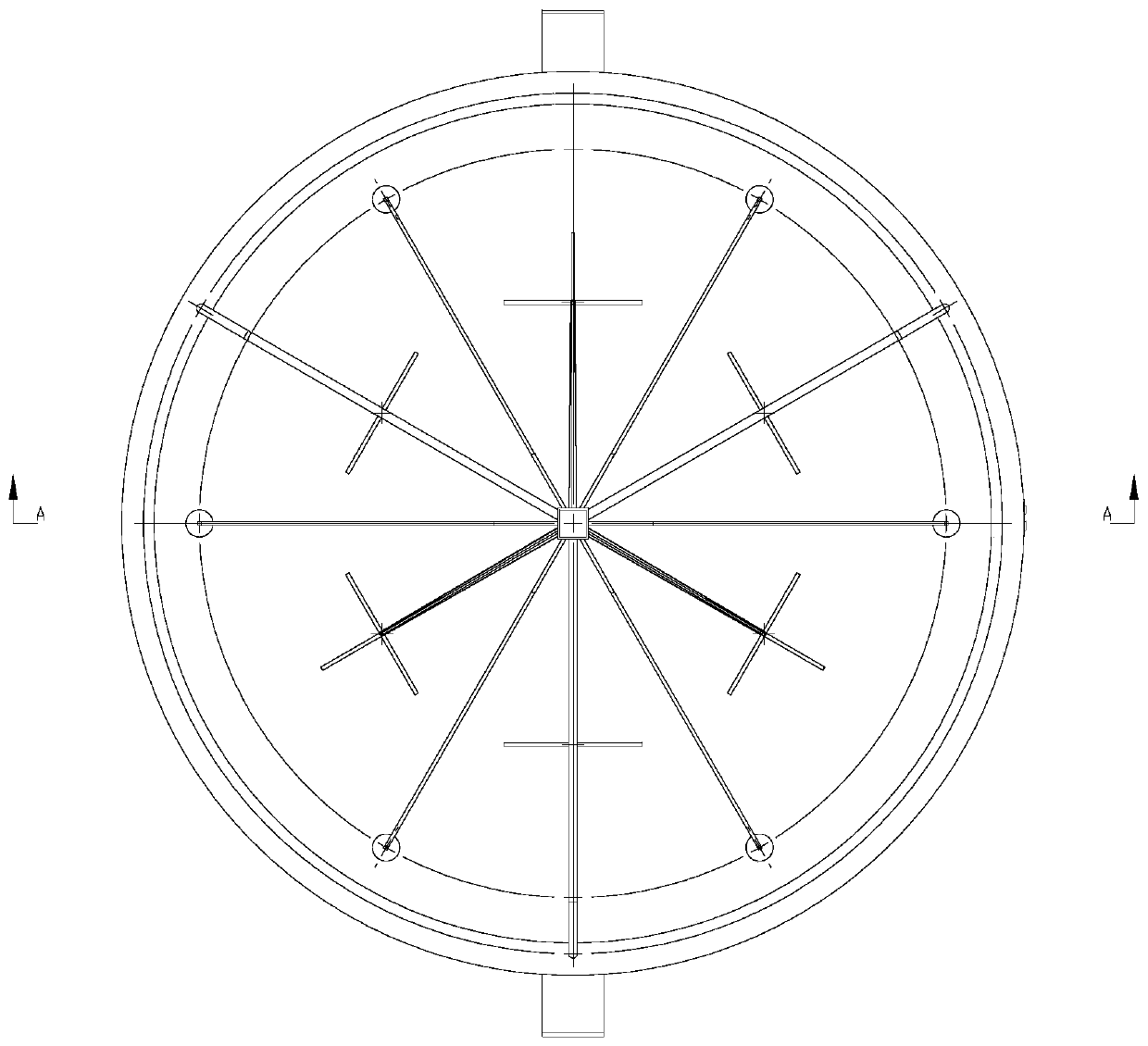

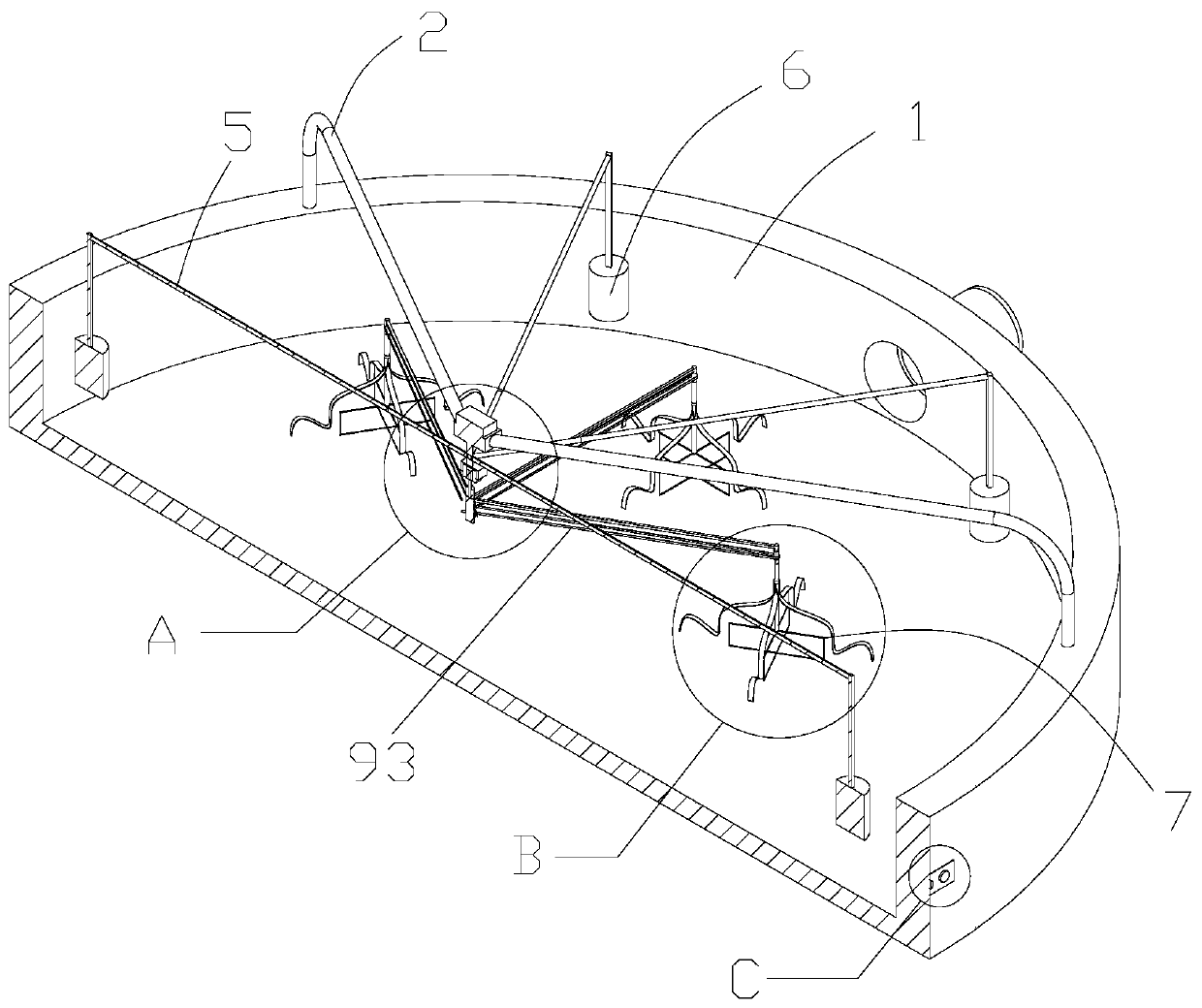

[0033] Such as Figure 1-9 As shown, a metal product electroplating equipment includes an electrolytic tank 1, a support member 2, a power supply assembly 3, a connector 4, an anode rod 5, an inert anode 6, a cathode assembly 7, a motor assembly 8, and an intermediate piece 9;

[0034] Described electrolytic cell 1 comprises cell body 11, liquid inlet pipe 12, liquid outlet pipe 13, first end cap 14, second end cap 15 and switch panel 16; The liquid inlet pipe 12 and the liquid outlet pipe 13 are opened in the side wall of the tank body 11; Removable; the second end cover 15 is screwed on the liquid outlet pipe 13, so that the second end cover 15 is detachable relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com