Foil type electrode organic thin film winding type Y capacitor

A technology of organic thin film and organic thin film layer, applied in the field of capacitors, which can solve the problems of high cost, large capacity change with temperature, and small capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

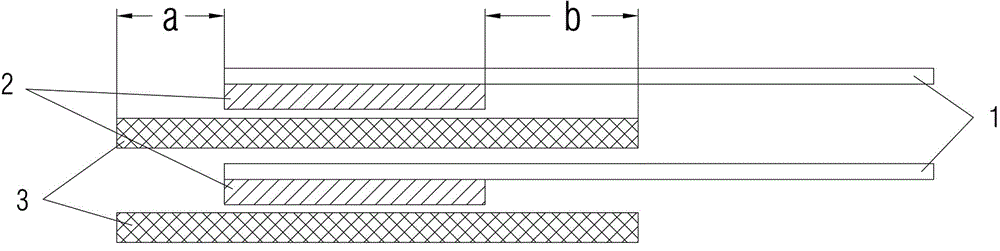

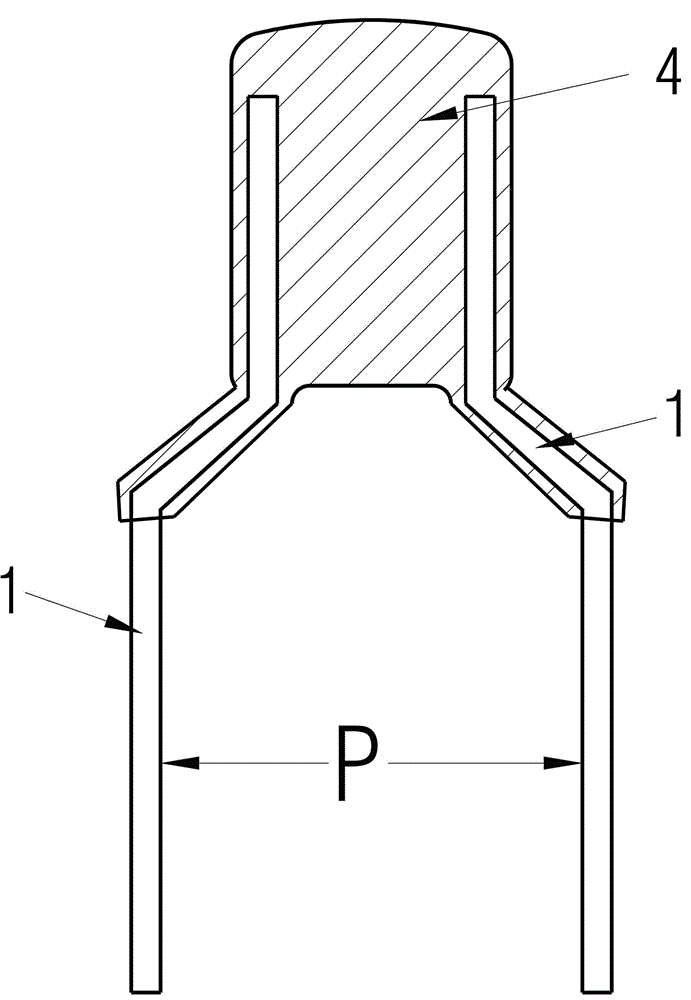

[0013] Such as figure 1 , 2 As shown, the electrode proposed by the present invention is a foil-type organic film winding type Y capacitor, including a pair of electrodes 1, the lower end of the electrode 1 is welded with an aluminum foil layer 2, and the lower end of the aluminum foil layer 2 is pasted with an organic thin film layer 3, and the organic thin film layer Both ends of 3 are provided with a reserved width relative to the aluminum foil layer 2, wherein the reserved width away from the electrode end is a, a is at least 2 mm, and the reserved width near the electrode end is b, and b is at least 3 mm; the organic film Layer 3 is made by laminating two organic films with a thickness of at least 13 microns. The exterior and gap of aluminum foil layer 2 and organic film layer 3 are pre-packaged and cured with liquid epoxy resin, and powder epoxy resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com