A kind of LED flexible board light source module and manufacturing method thereof

A technology of LED light source and light source module, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems affecting the light output efficiency and service life of LED light sources, the increase of heat dissipation channels of LED light sources, and the poor heat dissipation of LED light sources, etc., so as to avoid Poor heat dissipation, realize the separation of electricity and heat, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

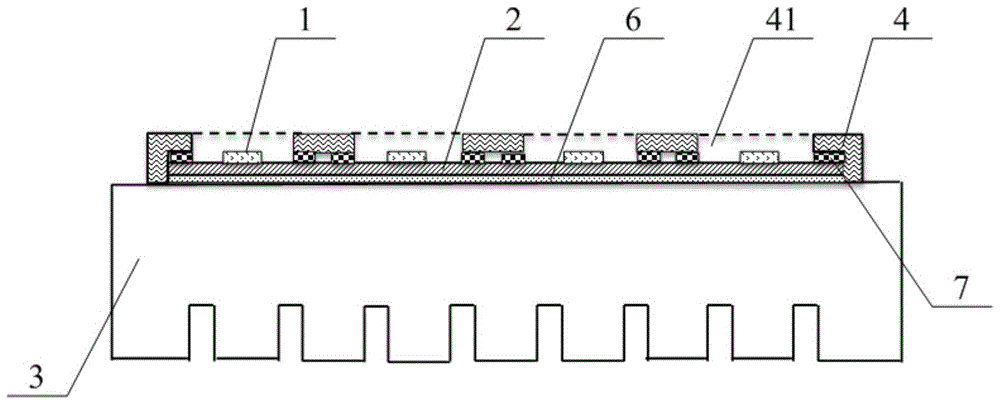

[0051] Such as figure 1 As shown, the LED flexible board light source module provided in this embodiment includes: LED light source 1, which is arranged on the soft substrate 2; heat dissipation member 3, on which the soft substrate 2 is arranged; conductive member 4, which covers on the soft substrate 2 and the heat dissipation member 3 , and the conductive member 4 is electrically connected to the soft substrate 2 .

[0052] It installs the LED light source 1 on the soft substrate 2, then arranges the soft substrate 2 on the heat dissipation member 3, and uses the conductive member 4 to electrically connect the soft substrate 2, so that the LED light source 1 can dissipate heat through the heat dissipation member 3, Conducting electrical conduction through the conductive member 4, thereby realizing the separation of electricity and heat, improving the heat dissipation effect of the LED light source 1, effectively avoiding the problem of premature light decay of the LED light...

Embodiment 2

[0062] The LED flexible board light source module provided in this embodiment is further optimized on the basis of the LED flexible board light source module provided in the first embodiment, so most of its structure is the same as that of the LED flexible board light source module provided in the first embodiment. The groups are basically the same or similar, and will not be repeated here, and only the differences will be described below.

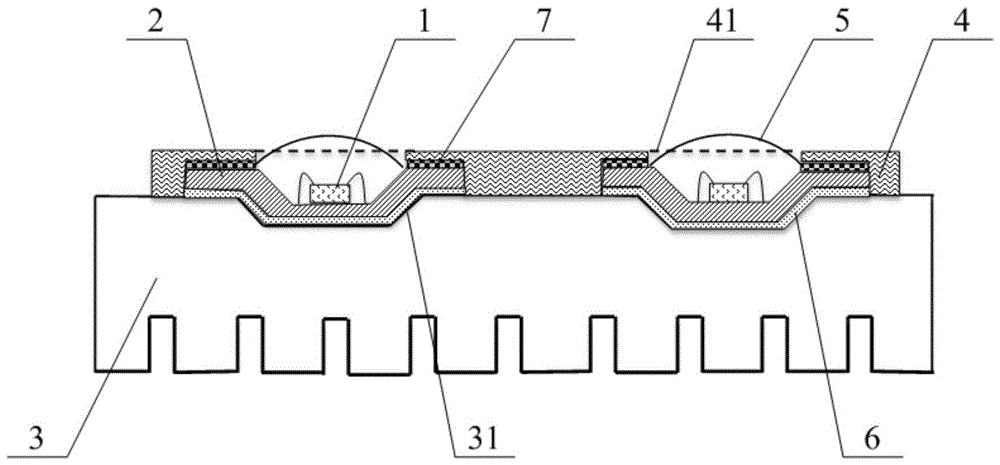

[0063] Such as figure 2 As shown, in this embodiment, the LED light source 1 is an LED chip, the LED chip is connected to the soft substrate 2, and the LED chip is packaged on the soft substrate 2 through the lens 5; further, the LED chip and the soft substrate 2 are positively connected.

[0064] The specific installation process is as follows: the LED chip is mounted on the soft substrate 2, and then the LED chip is fixed on the soft substrate 2 through processes such as die bonding, wire bonding, glue dispensing, and curing.

[0065] ...

Embodiment 3

[0071] The LED flexible board light source module provided in this embodiment is further optimized on the basis of the LED flexible board light source module provided in the second embodiment above, so most of its structure is the same as that of the LED flexible board light source module provided in the second embodiment. The groups are basically the same or similar, and will not be repeated here, and only the differences will be described below.

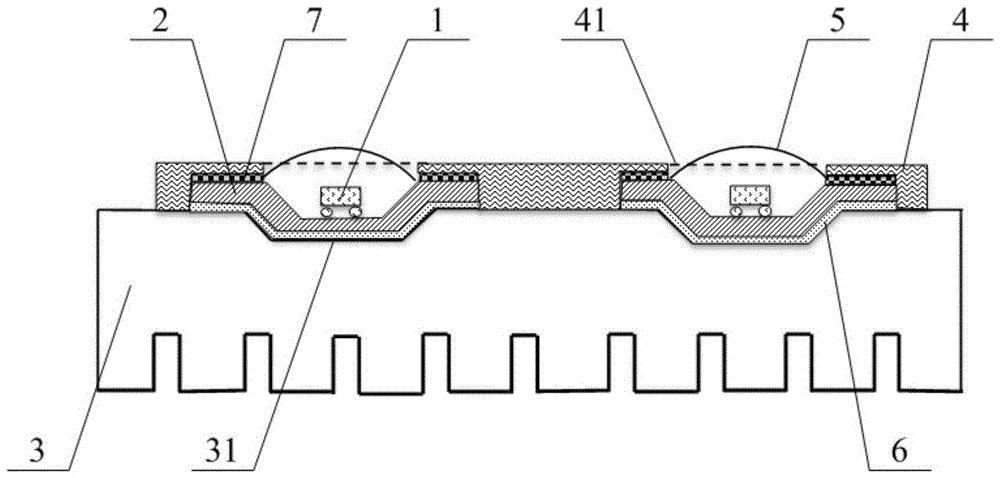

[0072] Such as image 3 As shown, in this embodiment, the LED light source 1 is an LED chip, the LED chip is connected to the soft substrate 2, and the LED chip is packaged on the soft substrate 2 through the lens 5; further, the LED chip and the soft substrate 2 are flip-chip connected.

[0073] Among them, since the LED chip is flip-chip mounted on the soft substrate 2, it can skip the wiring process in the second embodiment, and the LED chip is directly installed on the soft substrate 2 after dispensing, curing and other process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com