Utility vehicle chassis and method for manufacturing a profile longitudinal beam for a utility vehicle chassis of said type

A commercial vehicle, elongated technology, applied to vehicle components, substructure, transportation and packaging, etc., can solve the problem of weight reduction, achieve the effect of low processing time, simple tools, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

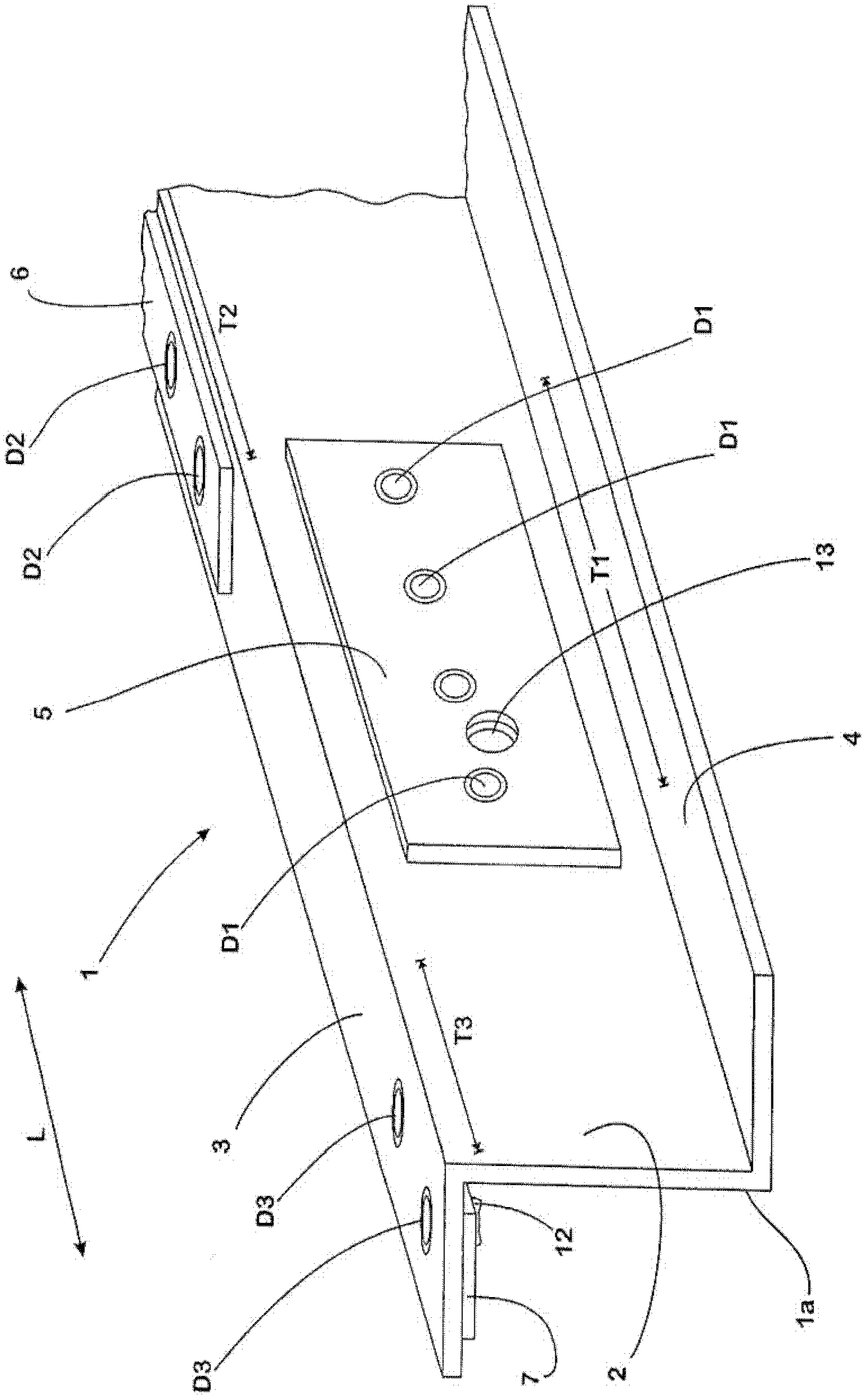

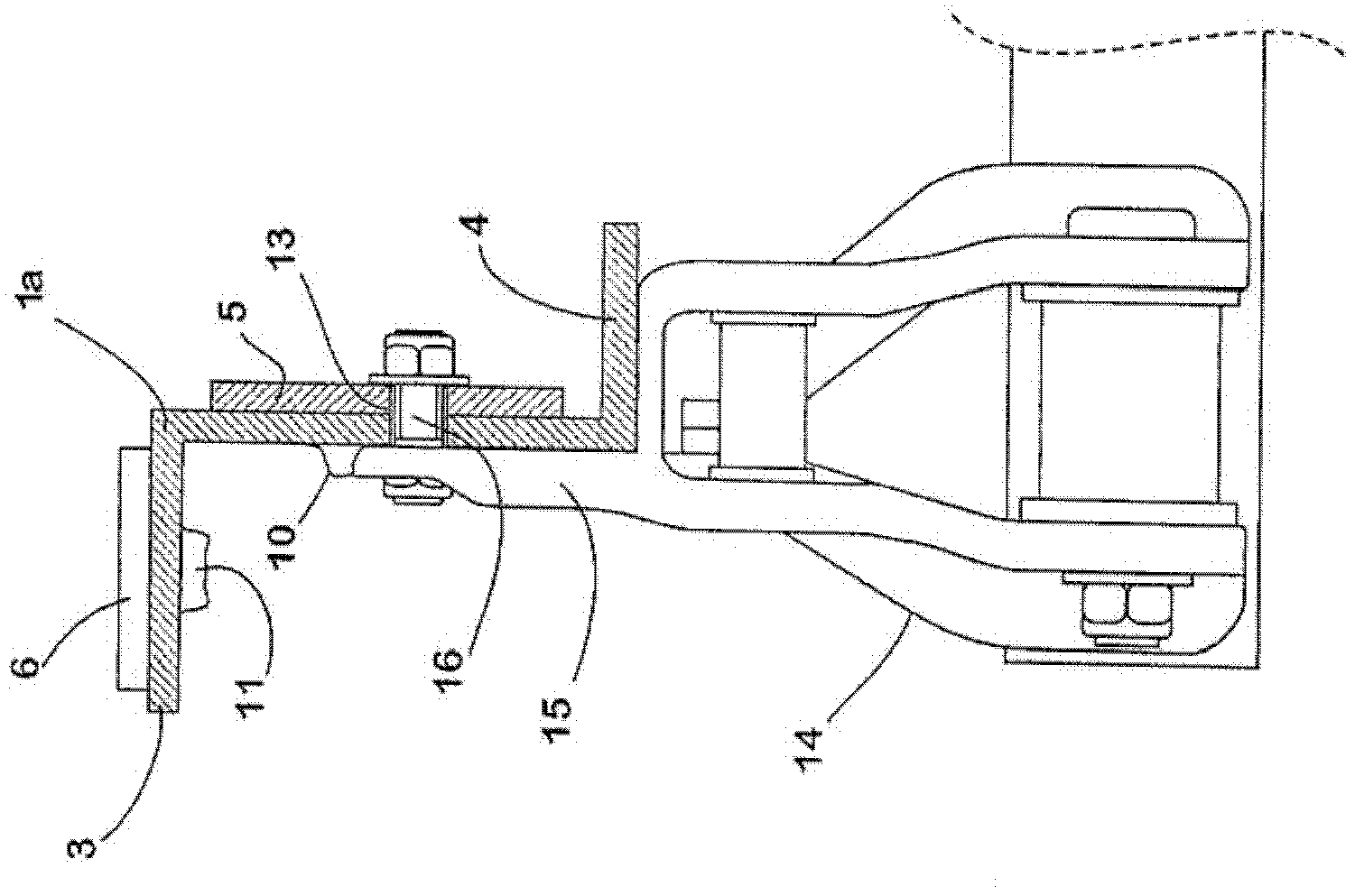

[0141] The elongated carrier 1 shown in the figure relates to the longitudinal beams of the chassis, not shown further here, which are used for semi-trailers of tractors, which are also not shown here. In practice, the elongated carrier 1 extends over the main part of the length of the relevant semi-trailer.

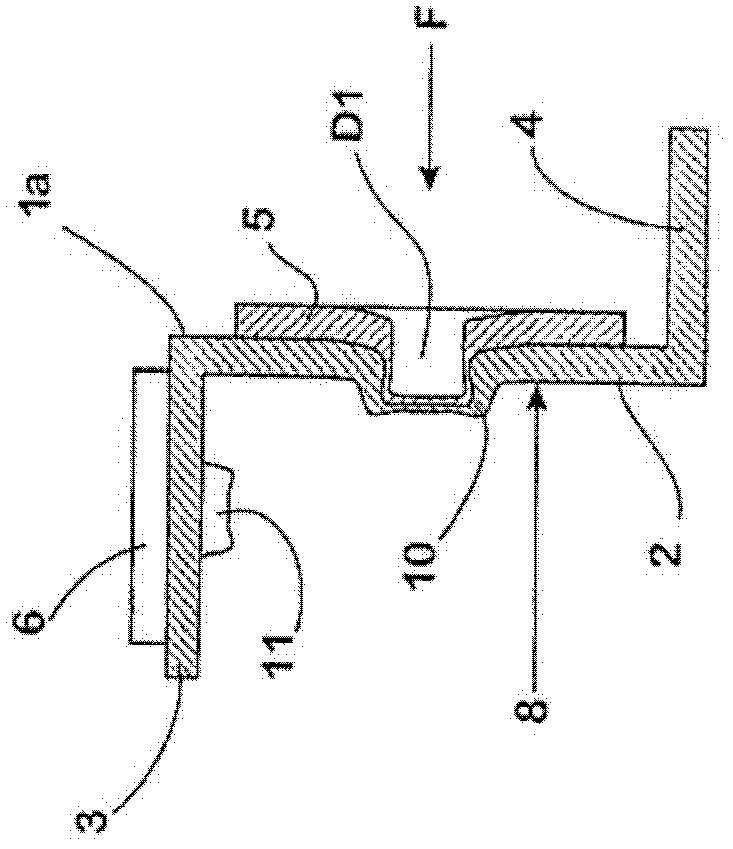

[0142] The elongated carrier 1 includes a Z-shaped elongated profile 1a, which is formed in one piece from a galvanized large steel plate with a thickness of 4-5 mm. In this regard, the elongated profile 1a has a web 2, an upper flange section 3 and a lower flange section 4 arranged vertically in the installation position, the upper flange section being formed on the upper longitudinal edge of the web 2 The upper side and the web 2 extend laterally at right angles, and the lower flange section is formed on the lower longitudinal edge of the web 2 and extends laterally at right angles to the web 2 and opposite to the web 2 Out.

[0143] The elongated profile 1a of the elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com