Industrialized processing method of silkworm excrement for feed

A processing method and technology of silkworm excrement, which is applied in the field of industrialized processing of silkworm excrement for feed, can solve the problems of difficulty in purchasing silkworm excrement, wasting time, and difficult processing, and achieve the effects of rapid and large-scale promotion, diverse technological uses, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

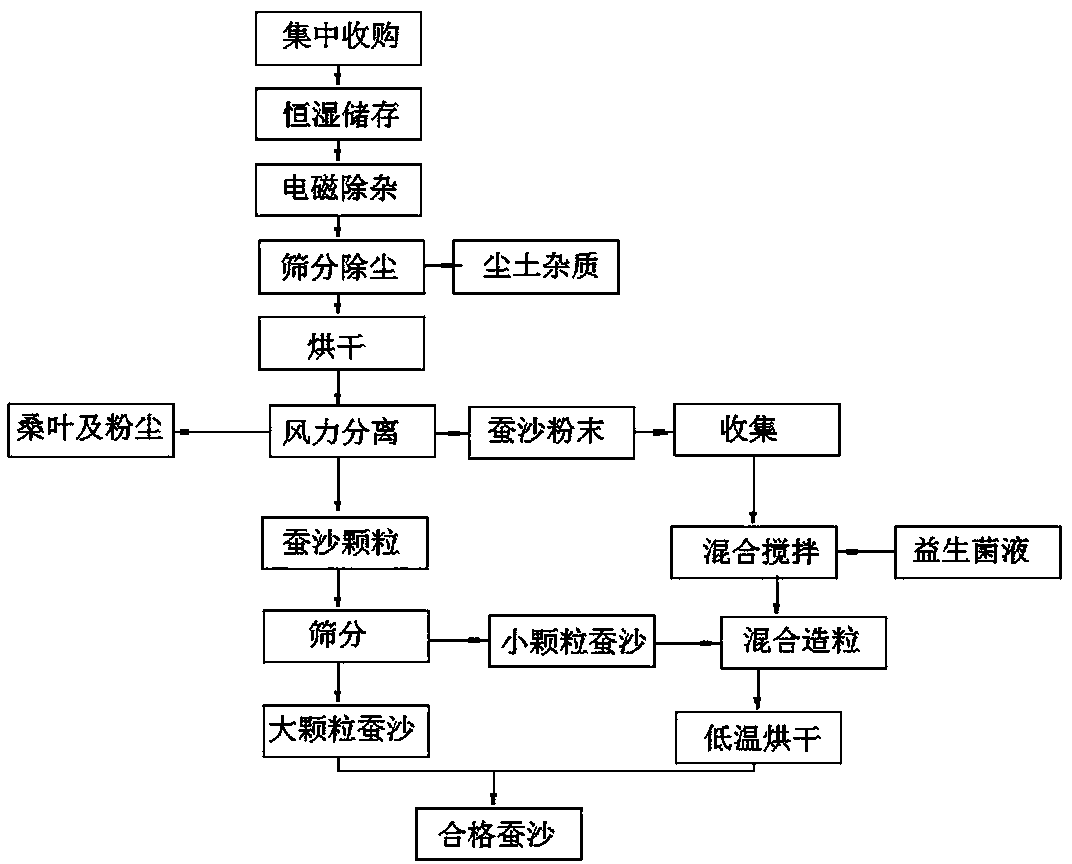

[0026] Such as figure 1 Shown a kind of silkworm excrement industrialized processing method for feed, its step is as follows:

[0027] a. Centralized purchase: purchase silkworm excrement directly from farmers, including centralized purchase, constant humidity storage, screening and dust removal, drying, wind separation, collection, sub-sieving, low-temperature drying, qualified silkworm excrement, and the purchased silkworm excrement directly Sent to processing enterprises, these silkworm excrement farmers only need to collect them directly, without the need to separate impurities and dry them in the sun;

[0028] b. Constant humidity storage: Send the purchased silkworm excrement to the constant humidity storage warehouse. The constant humidity storage warehouse is equipped with a drying device. The drying device keeps the humidity in the constant humidity storage warehouse at 14-18%. After ~15 days, it will be transferred to the general warehouse for storage;

[0029] c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com