Method for spraying robot spatial path planning

A spraying robot and space path technology, applied in the field of intelligent robots, can solve problems such as inability to use complex curved workpiece surface spraying operations, and no planning method for spraying space paths, etc., to achieve the effect of improving work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

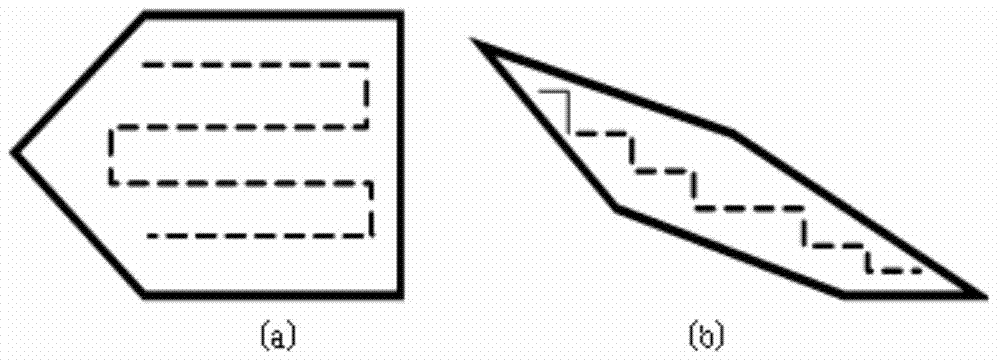

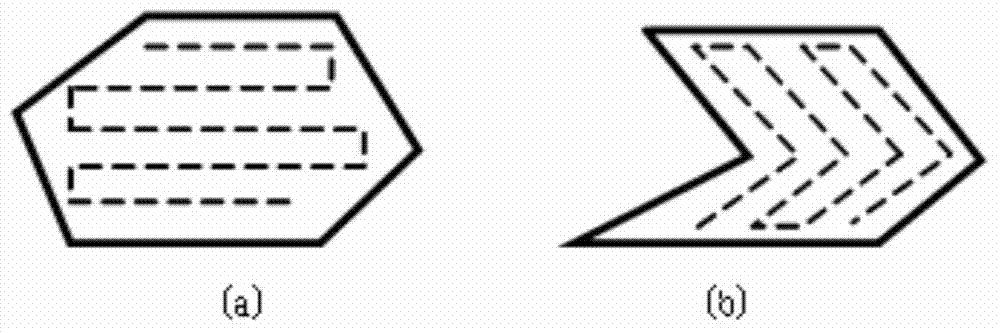

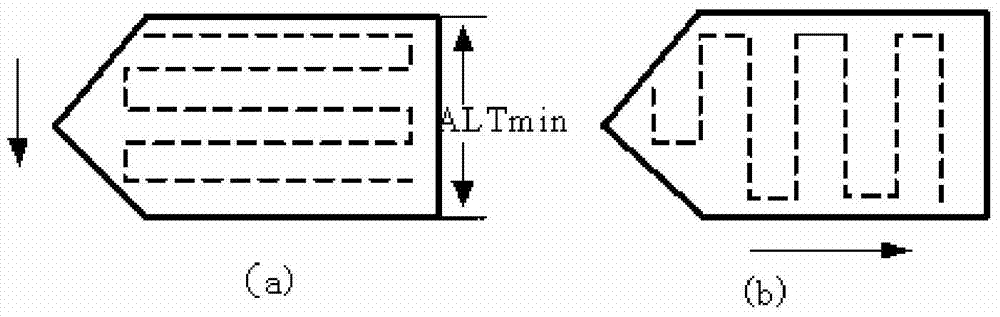

[0041] The implementation steps of the present invention are composed of complex curved surface slices and spraying path planning on each slice. The specific implementation methods are as follows.

[0042] 1. Complex Surface Fragmentation

[0043] Complex surface sharding is mainly based on surface topology. Suppose a complex surface M c After triangular meshing, it is expressed as:

[0044] M c = ∪ i = 1 n T i

[0045] In the formula, T i Indicates the i-th triangular face, and n represents the total number of triangular faces. The calculation method of the average normal vector of a complex surface is:

[0046] n b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com