Multi-path vibrating screen machine

A vibrating sieve and trajectory technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of affecting the work of the sieve machine and blocking the sieve holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

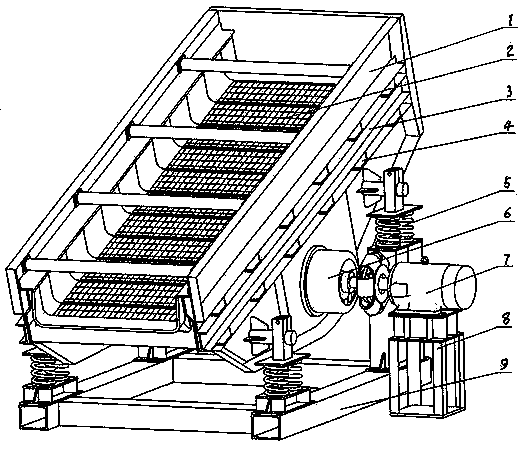

[0008] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention is an improvement on the basis of the existing circular vibration screening machine. Box 1, a resonance frame 3 is installed on the screen box 1 by shearing the rubber spring 4, a polyurethane screen 2 is installed on the inner bottom surface of the screen box, and the vibrator 6 is installed on the bottom of the screen box. A motor frame 8 is installed on the side, and a motor 7 linked with the vibrator is installed on the motor frame. After the above improvements, the material generates an elliptical motion trajectory at the feed end of the sieve machine during work, a circular motion trajectory at the middle part, and a reverse elliptical motion trajectory at the discharge end, so that the material can be quickly layered and fully layered during the screening process. Screening, and use the characteristics of polyurethane screen to generate revibration accelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com