Mechanical clamping cut-off tool

A technology for cutting off knives and machine clips, which is applied in the attachments of tool holders, tools for lathes, turning equipment, etc., can solve the problems of uneven cutting feed, the cutting edge cannot be very wide, and the smoothness is affected, and the sharpening of the knife can be achieved. The effect of time reduction, labor intensity reduction, and widespread promotion of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

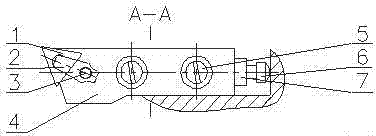

[0014] combine figure 1 , this embodiment includes a blade 1, a pressure plate 2, a position clamping screw 3, a cutter body 4, a position positioning screw 5, a length positioning screw 6 and a length locking nut 7, and the blade 1 is fixed on the cutter body 4 through the pressure plate 2, The pressing plate 2 is installed on the machine tool through the position clamping screw 3 , the length positioning screw 6 is arranged on the rear end of the cutter body 4 , and the length locking nut 7 is arranged on the length positioning screw 6 . The blade 1 is composed of three equal triangular cutting edges, which are installed on the front end of the cutter body 4 respectively. The position clamping screw 3 includes two screws arranged side by side, and a nut is installed on the screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com