Method for preparing stained glass grains with discarded and used glass and application thereof

A technology for colored glass and waste glass, applied in the removal of solid waste, floors, buildings, etc., can solve the problems of ecological environment impact, abundant mineral resources, poor weather resistance, etc., achieve long service life, increase color layer life, construction Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

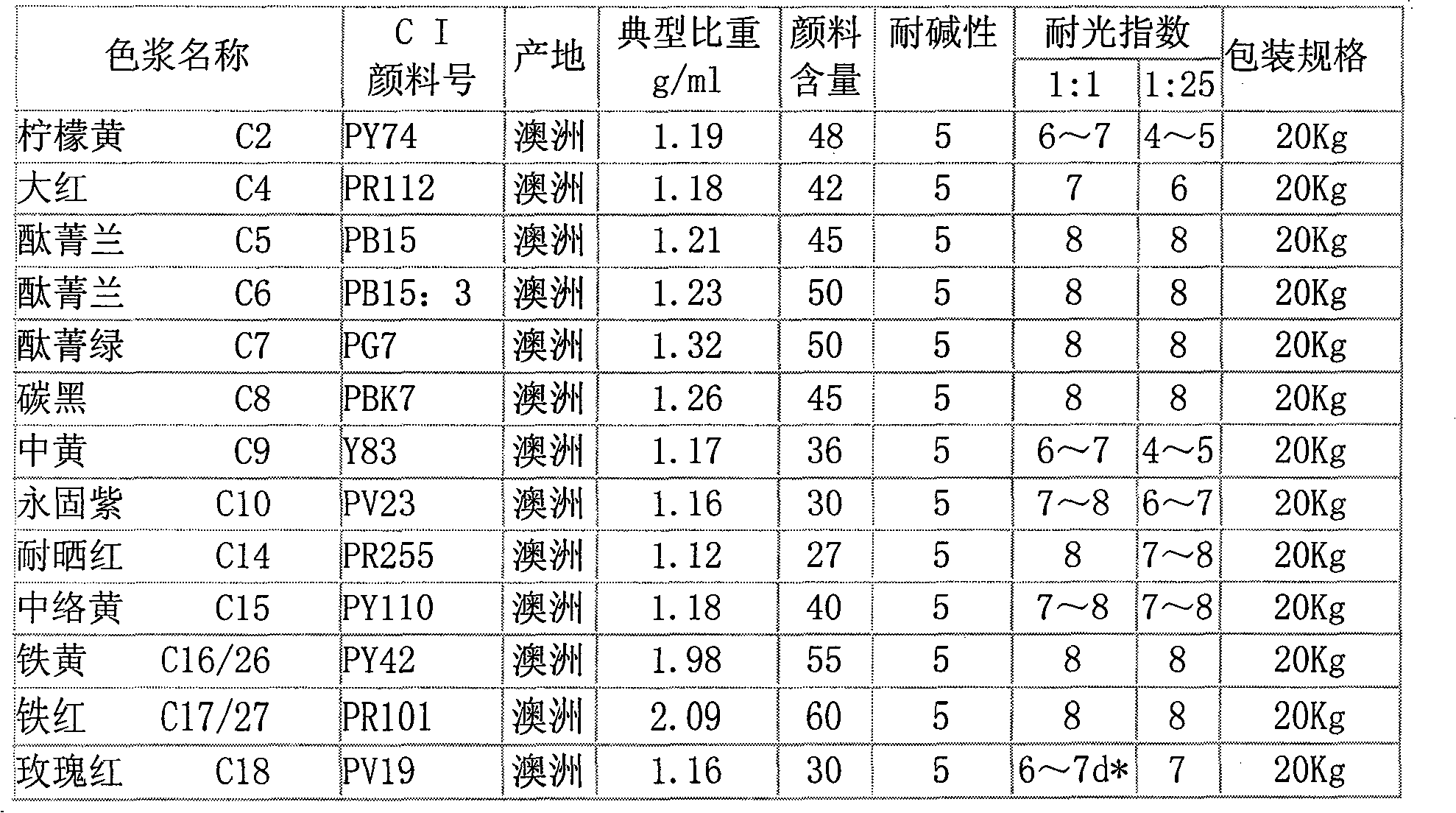

[0027] Weigh 10,000 parts of crushed waste glass grains and put them into the blender. The glass grains should be clean and dust-free. 100 parts of acrylic emulsion, 2.5 parts of aziridine crosslinking agent, 3 parts of propyltrimethoxysilane coupling agent, 0.4 parts of polyethylene wax, 25 parts of PR112 big red water-based color paste, five kinds Mix the materials together, stir evenly, and put it into the blender to stir with the glass grains for about 5-10 minutes. The colored glass grains are transported to the drying equipment through the conveyor belt and dried for about 5 minutes. The drying temperature is set between 50 and 120°C. The dryness of the red glass grains after the furnace is loose and not agglomerated. good.

[0028] During construction, the red glass grains prepared above can be directly applied to the surface of concrete, asphalt, floor tiles, mud tiles or wood, or coated with paint, glue and other coatings on the wall and ground to make a floor More ...

Embodiment 2

[0036] Weigh 10,000 parts of crushed waste glass grains and put them into the blender. The glass grains should be clean and dust-free. With 150 parts of acrylic emulsion, 4 parts of aziridine crosslinking agent, 4.5 parts of propyltrimethoxysilane coupling agent, 0.6 part of polyethylene wax, 40 parts of PB15 No. phthalocyanine blue aqueous color paste, Mix the five materials together, stir evenly, and put them into the blender and stir with the glass grains for about 5-10 minutes. Transport the colored glass grains to the drying equipment for about 10 minutes through the conveyor belt, and set the drying temperature between 50 and 120°C to ensure that the blue glass grains after being released from the furnace are dry and loose and not agglomerated better.

[0037]During construction, the blue glass grains prepared above can be directly applied to surfaces such as concrete, asphalt, floor tiles, mud tiles, or wood, or coated with paint, glue, etc. Ping is more affordable th...

Embodiment 3

[0045] Weigh 10,000 parts of crushed waste glass grains and put them into the blender. The glass grains should be clean and dust-free. With 200 parts of acrylic emulsion, 6 parts of aziridine crosslinking agent, 6.5 parts of propyltrimethoxysilane coupling agent, 0.8 parts of polyethylene wax, 65 parts of PY74 lemon yellow water-based color paste, five Mix the two materials together, stir evenly, and put them into the blender and stir with the glass grains for about 5-10 minutes. The colored glass grains are conveyed to the drying equipment for drying for about 10 minutes through the conveyor belt. The drying temperature is set between 50 and 120°C. good.

[0046] During construction, the yellow glass grains prepared above can be directly applied to the surface of concrete, asphalt, floor tiles, mud tiles or wood, or coated with paint, glue and other coatings on the wall and ground to make a floor More affordable than ceramic tiles, long service life and cost-effective. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com