Nano compound, multifunctional oil-resistant, waterproof ultraviolet-resistant textile finishing agent and preparation method thereof

A nano-composite, multi-functional technology, applied in textiles, papermaking, fiber treatment, etc., to achieve the effects of improved color fastness, excellent sun protection performance, and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] A nano-composite water-repellent multifunctional finishing agent for textiles that is oil-repellent, water-repellent, and sunscreen, including 2-8% of nano-titanium dioxide, 5-70% of water-soluble acrylic fluorocarbon resin or water-soluble acrylic partial difluoride resin, and 2-10% % cross-linking agent, the cross-linking agent refers to Li Teshi or 2D resin or EH cross-linking agent, 2-20% modifier, the modifier refers to Hobster, 2-8 % moisture-absorbing and perspiration-wicking agent, said moisture-absorbing and perspiration-wicking agent refers to Ciba moisture-absorbing and perspiration-wicking agent, 22 to 50% water.

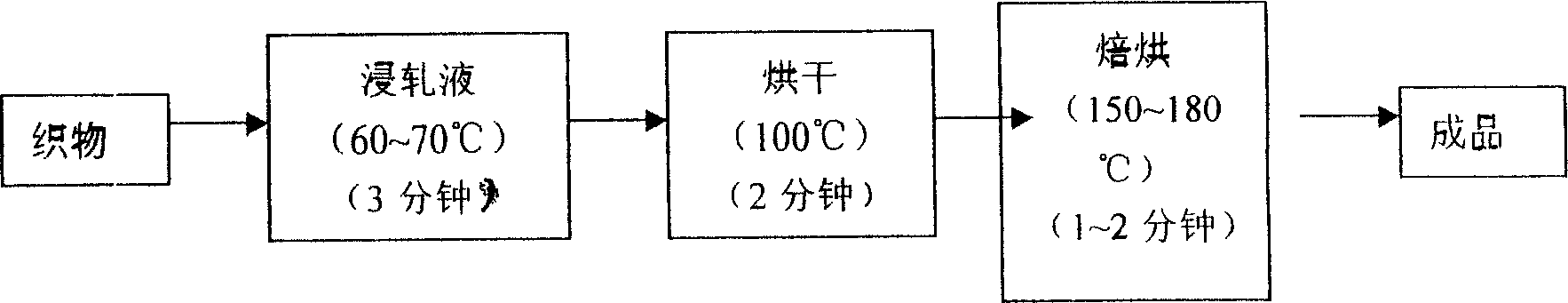

[0115] figure 2 Shown, the method for preparing product is carried out according to the following steps:

[0116] Preparation method:

[0117] a. Weigh nano-titanium dioxide, water-soluble acrylic fluorocarbon resin or water-soluble acrylic partial fluoride resin, crosslinking agent, modifier, moisture-absorbing and sweat-wicking agent, and wat...

Embodiment 2

[0128] Sunscreen multifunctional finishing agent, including 2kg of nano-titanium dioxide, 60kg of water-soluble acrylic partial fluoride resin, 9kg of Litex, 2 Hobster, 2 Ciba moisture-absorbing and perspiration-wicking agents, and 25kg of water.

[0129] The method for preparing product is carried out according to the following steps:

[0130] Preparation method:

[0131] a. Weigh nano-titanium dioxide, water-soluble acrylic partial fluoride resin, Litex, Hobster, moisture-wicking agent, and water in sequence according to the specified ratio;

[0132] b. Heat the weighed water to 60°C, add the weighed titanium dioxide into it, vibrate with a 500w ultrasonic oscillator for 10 minutes, and stir at a high speed for 10 minutes with a high-shear emulsifier until the nano-titanium dioxide is completely uniformly dispersed;

[0133] c. Keep at 65°C, add Liteshi, Hobster, and moisture-absorbing perspiration agent to b in turn, stir at high speed for 3 minutes, until they are complet...

Embodiment 3

[0142] A water-cleaning sunscreen multifunctional finishing agent for textiles, including 5kg of nano-titanium dioxide, 35kg of water-soluble acrylic fluorocarbon resin, 6kg of Litex, 5 Hobster, 7 Ciba moisture-absorbing and sweat-wicking agent, and 42kg of water.

[0143] The method for preparing product is carried out according to the following steps:

[0144] Preparation method:

[0145] a. Weigh nano-titanium dioxide, water-soluble acrylic fluorocarbon resin, EH cross-linking agent, Hobster, moisture-absorbing and sweat-wicking agent, and water in sequence according to the prescribed ratio;

[0146]b. Heat the weighed water to 70°C, add the weighed titanium dioxide into it, vibrate with a 500w ultrasonic oscillator for 15 minutes, and stir at a high speed for 10 minutes with a high-shear emulsifier until the nano-titanium dioxide is completely uniformly dispersed;

[0147] c. Keeping at 65°C, add the weighed cross-linking agent EH, Hobster, and moisture-absorbing perspira...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com