Thin-specification container board and manufacturing method thereof

A container and thin-gauge technology, which is applied in the field of thin-gauge container boards and their preparation, can solve the problems of high cost, achieve reasonable content, suppress copper brittle defects, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present application also provides a method for preparing a thin container board, comprising the following steps:

[0030] Heating the steel slab composed of the above, the furnace temperature in the soaking furnace or the first 4 zones of the heating furnace is controlled at 1200-1300°C, the temperature of the steel slab out of the furnace is 1120-1160°C, and the time in the furnace is within 40min;

[0031] The heated steel slab is continuously rolled to obtain a steel plate, and coiled to obtain a steel coil; the initial rolling temperature of the continuous rolling is 1120-1160°C, and the final rolling temperature is 820-920°C.

[0032]Steel billets can be prepared by various methods, such as desulfurization pretreatment of blast furnace molten iron, the desulfurization pretreated blast furnace molten iron is mixed into oxygen top-bottom composite blowing converter (such as 100t level) for smelting, and the smelted molten steel is treated by argon blowing and calc...

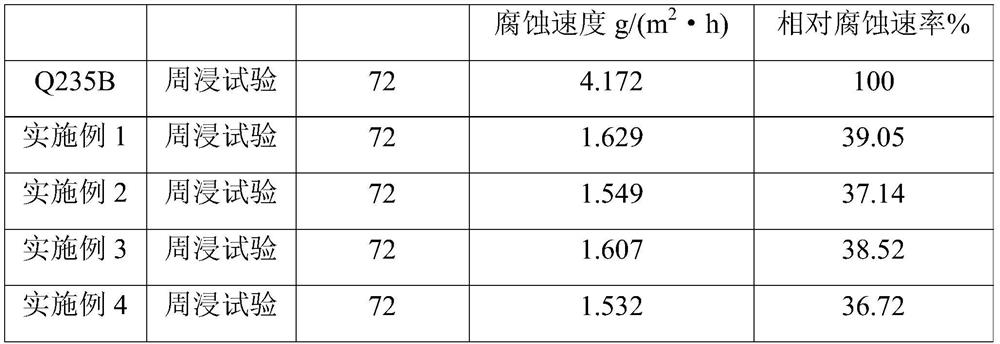

Embodiment 1

[0048] The smelted molten steel (the chemical composition weight percentage of molten steel is: C: 0.05%, Si: 0.25%, Mn: 0.35%, P: 0.08%, S: 0.004%, Cu: 0.26%, Cr: 0.35%, Ti : 0.035%, the balance is Fe and unavoidable impurity elements), cast into a 70mm thick slab, the continuous casting casting speed is 4.4m / min, the slab entering furnace temperature is 940°C, and the slab is sent into the tunnel heating furnace Heating; the temperatures in zones 1-7 of the heating furnace are 1250°C, 1265°C, 1260°C, 1255°C, 1230°C, 1220°C, and 1205°C respectively, and the slab stays in the furnace for 29 minutes; the temperature at the entrance of the rolling mill is 1140°C, and the exit of the final rolling The temperature is 910°C, the coiling temperature is 610°C, and finally rolled into container plates with a thickness of 1.6mm. The yield strength of the steel plate is 446MPa, the tensile strength is 535MPa, the elongation is 25%, and d=a is qualified for cold bending.

Embodiment 2

[0050] The smelted molten steel (the chemical composition weight percentage of molten steel is: C: 0.06%, Si: 0.29%, Mn: 0.4%, P: 0.09%, S: 0.003%, Cu: 0.29%, Cr: 0.4%, Ti : 0.032%, the balance is Fe and unavoidable impurity elements), cast into a 60mm thick slab, the continuous casting casting speed is 4.6m / min, the slab entering furnace temperature is 960°C, and the slab is sent into the tunnel heating furnace for Heating; the temperatures in zones 1-7 of the heating furnace are 1260°C, 1265°C, 1265°C, 1250°C, 1240°C, 1220°C, and 1210°C respectively, and the slab stays in the furnace for 33 minutes; the temperature at the entrance of the rolling mill is 1155°C, and the exit of the final rolling The temperature is 910°C, the coiling temperature is 610°C, and finally rolled into container plates with a thickness of 1.6mm. The yield strength of the steel plate is 452MPa, the tensile strength is 546MPa, the elongation is 27%, and d=a is qualified for cold bending.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com