Jade glaze of jun procelain

A technology of jade and Jun porcelain, applied in the field of Jun porcelain jade glaze, can solve the problems of color difference, weak jade texture, low yield, etc., and achieve the effects of improving yield, reducing pollution, and overcoming poor color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

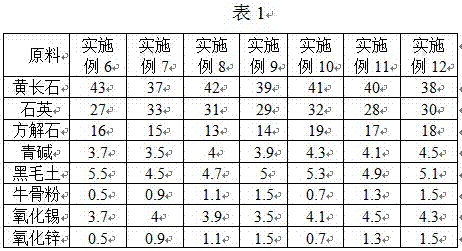

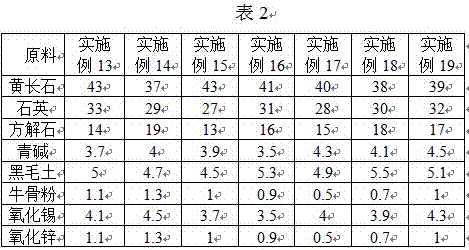

[0016] A Jun porcelain jade glaze, which is prepared from the following raw materials in parts by weight: 37-43 parts of feldspar, 27-33 parts of quartz, 13-19 parts of calcite, 3.5-4.5 parts of cyanine, 4.5-5.5 parts of black wool soil, 1 part of bovine bone powder, 3.5-4.5 parts of tin oxide, 0.5-1.5 parts of zinc oxide.

[0017] The preparation method of the above-mentioned Jun porcelain moon white glaze comprises the following steps:

[0018] (1) Mix the above raw materials with water, and ball mill to obtain glaze slurry;

[0019] (2) Glazing;

[0020] (3) Firing, the firing temperature is 1260-1300°C;

[0021] The firing process specifically includes the following steps: ①Oxidation period: Put the glazed green body into the kiln and fire it in an oxidizing atmosphere, so that the temperature rises to 810-910℃ evenly in 3-4 hours; ②Under a reducing atmosphere, Raise the temperature uniformly to 1260-1300°C in 4-5h; ③Under a reducing atmosphere, keep at 1260-1300°C for ...

Embodiment 2

[0023] A Jun porcelain jade glaze, prepared from the following raw materials in parts by weight: 40 parts of feldspar, 30 parts of quartz, 16 parts of calcite, 4 parts of cyanine, 5 parts of black hair soil, 1 part of bovine bone powder, 4 parts of tin oxide, 1 part of zinc oxide.

[0024] The preparation method of above-mentioned Jun porcelain jade glaze, comprises the following steps:

[0025] (1) Mix the above raw materials with water, ball mill, and pass through a 200-mesh sieve to obtain glaze slurry;

[0026] (2) Glazing;

[0027] (3) Firing, which specifically includes the following steps: ① Oxidation period: Put the glazed green body into the kiln and fire it in an oxidizing atmosphere, so that the temperature rises to 900°C evenly in 3.5 hours; ② Under a reducing atmosphere, Raise the temperature uniformly to 1280°C in 4.5 hours; ③Under a reducing atmosphere, keep at 1280°C for 25 minutes; ④Cool to room temperature to prepare.

[0028] The Jun porcelain jade glaze ...

Embodiment 3

[0030] A Jun porcelain jade glaze, prepared from the following raw materials in parts by weight: 40 parts of feldspar, 30 parts of quartz, 16 parts of calcite, 4 parts of cyanine, 5 parts of black hair soil, 1 part of bovine bone powder, 4 parts of tin oxide, 1 part of zinc oxide.

[0031] The preparation method of above-mentioned Jun porcelain jade glaze, comprises the following steps:

[0032] (1) Mix the above raw materials with water, ball mill, and pass through a 200-mesh sieve to obtain glaze slurry;

[0033] (2) Glazing;

[0034] (3) Firing, which specifically includes the following steps: ① Oxidation period: Put the glazed green body into the kiln, and fire it in an oxidizing atmosphere, so that the temperature rises to 910 ° C evenly in 3 hours; ② In a reducing atmosphere, make The temperature rises uniformly to 1300°C within 4 hours; ③Under a reducing atmosphere, keep at 1300°C for 30 minutes; ④Cool to room temperature to prepare.

[0035] The finished product rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com