Power Generation Welding Unit

A technology for electric welding units and generators, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increased maintenance costs, short service life, chassis vibration, etc., and achieves good cooling effect. Conducive to heat dissipation, the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

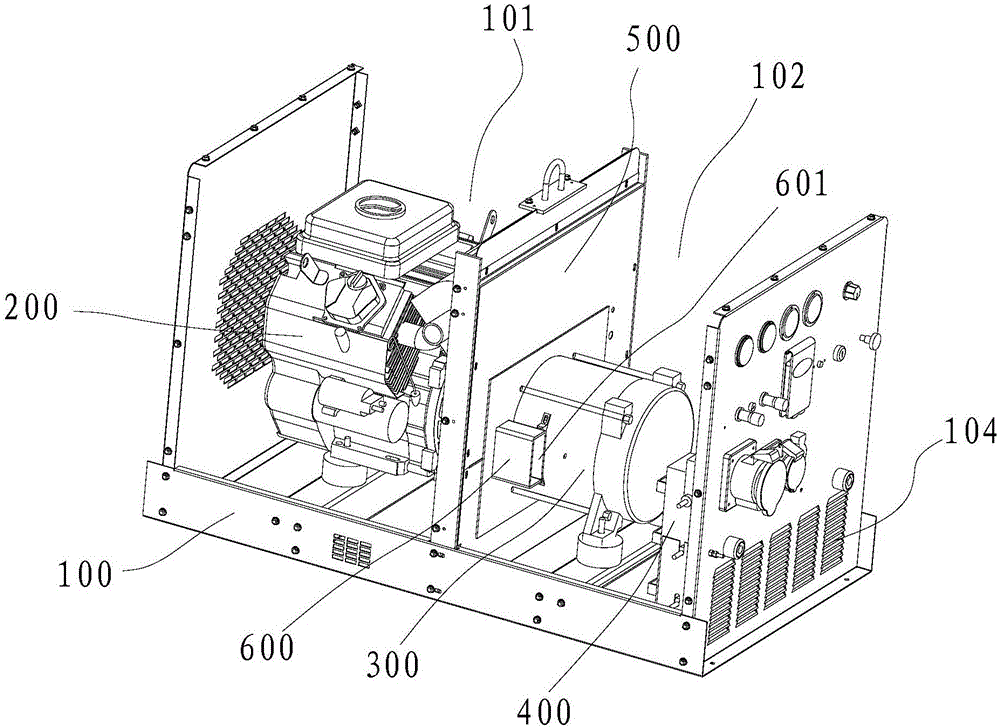

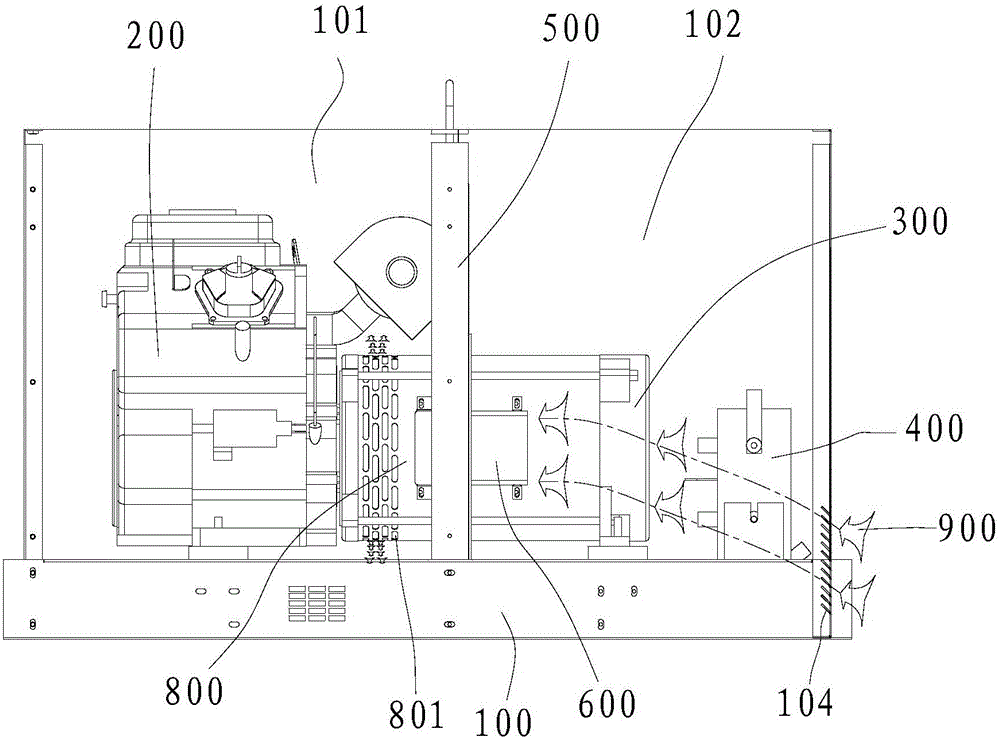

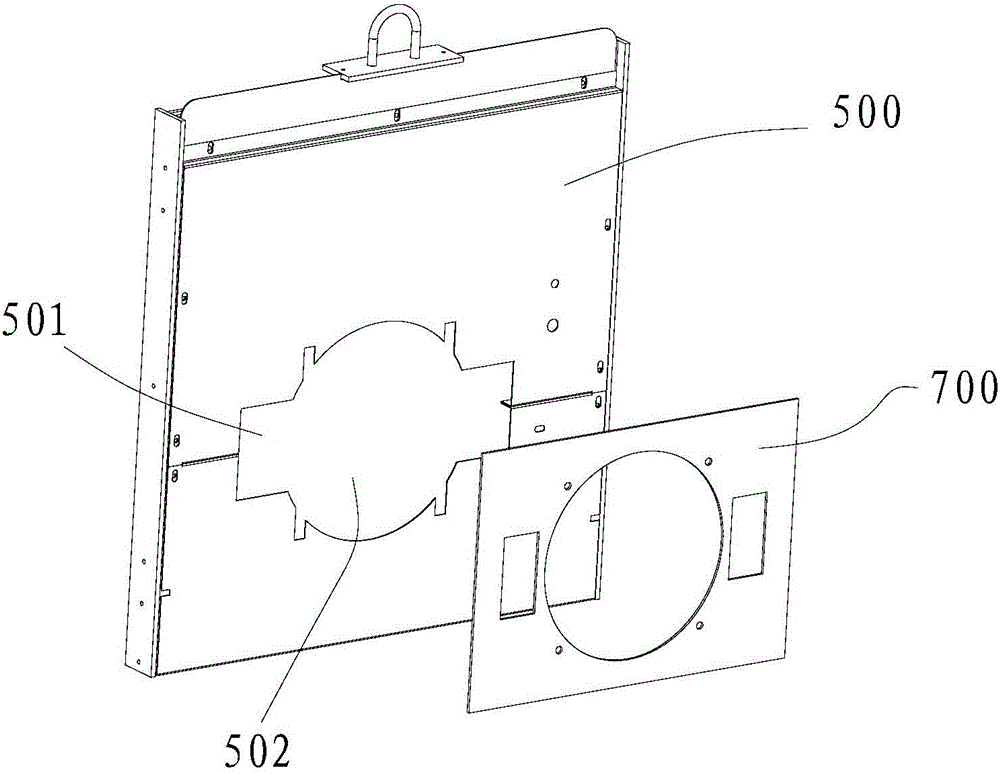

[0023] like Figure 1-5 As shown, in an embodiment of the present invention, a power generation electric welding unit includes a chassis 100, an internal combustion engine 200, a generator 300, a heating element 400, a centrifugal fan, and an air duct 600. The heating element 400 includes a reactance and a rectification assembly , the chassis 100 includes a first installation area 101 and a second installation area 102, the first installation area 101 and the second installation area 102 are separated by a partition 500, the internal combustion engine 200 is installed in the first installation area 101, and the generator 300 1. The heating element 400 is installed in the second installation area 102, the output end of the internal combustion engine 200 is connected to the generator 300, the heating element 400 is electrically connected to the generator 300, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com