Powders pneumatic conveyor trough

A technology of pneumatic conveying and powder materials, which is applied in conveyors, conveying bulk materials, transportation and packaging, etc. It can solve the problems of powder materials being easily broken, low crushing rate, and many failures, and achieve the effect of not easily broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

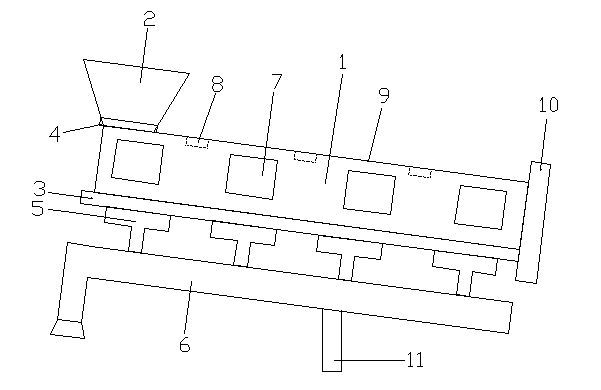

[0016] Such as figure 1 As shown, this embodiment provides a powder material pneumatic conveying tank, which includes a powder material chamber 1, a feed inlet 2 is provided on the upper left of the powder chamber 1, a filter plate 3 is provided below, and a feed inlet 2 is provided at the feed port 2. The material valve 4 is provided with a compressed air chamber 5 under the filter plate 3 , and a compressed air delivery pipe 6 is provided under the compressed air chamber 5 . The number of the compressed air chambers 5 is four and one is set every 80 cm. The shell of the powder chamber 1 is provided with an observation port 7 , a filling quantity sensor 8 is provided in the powder chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com