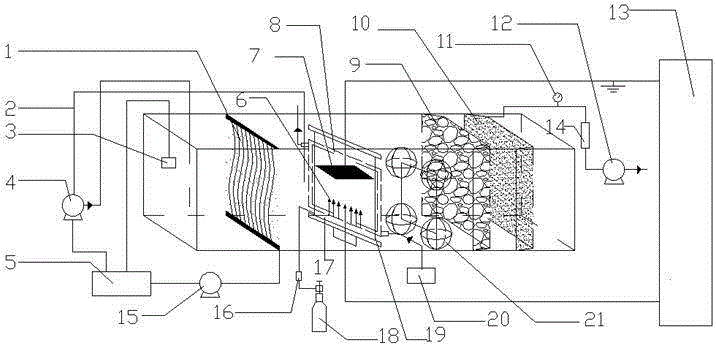

Method and system for recycling waste water by combining spark generation plasma with multistage membrane technology

A plasma and spark discharge technology, applied in the direction of oxidized water/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problems of increased cost, reduced wastewater discharge index, lack of etc., and achieve good environmental benefits and good economy Benefits, the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

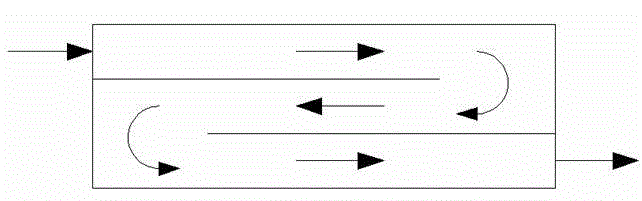

Method used

Image

Examples

Embodiment 1

[0054] (1) Use the water produced by the reverse osmosis membrane as the raw water, and run it at a pressure of 15Mpa for 24 hours. Measure the effluent flux J per unit pressure, unit area and unit time.

[0055] (2) Measure the initial flux J before the wastewater treatment operation 0 .

[0056] (3) Use standard flux J / J 0 The degree of decrease represents the degree of membrane fouling.

[0057] Observing the percentage decrease of membrane flux measured in the experiment, it is found that the membrane flux of the ultrafiltration membrane hardly changes after wastewater pretreatment and plasma modification, and the decrease percentage of the membrane flux of the reverse osmosis membrane is about 8%. The invention reduces membrane fouling very well.

[0058] The optimal conditions for the treatment of the present invention will be described in detail below by way of examples.

Embodiment 2

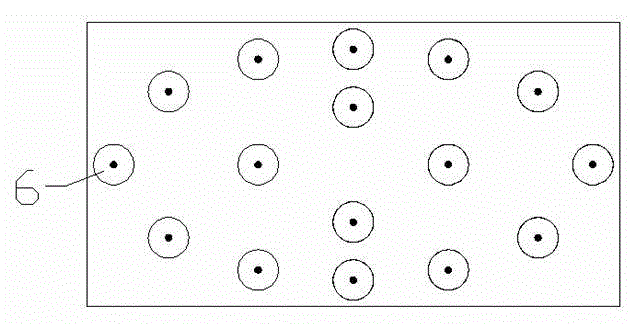

[0060] 1) Based on thyratron switching power supply and pin-plate reactor, spark discharge is used to generate plasma;

[0061] 2) Adjust the peak voltage of the pulse power supply to 15KV, and the pulse frequency to 100Hz;

[0062] 3) Adjust the height of the plate electrode so that the distance between the needle electrode and the plate electrode is 1.0 cm, and the weak acid brilliant blue simulated wastewater enters the plasma-modified multi-stage biofilm synergistic plasma technology push-flow reactor through the water inlet pump and the water inlet pipe. The water level in the device is controlled by the liquid level controller, and the pH value of the simulated printing and dyeing wastewater is adjusted to 4;

[0063] 4) Use the plasma generated by the pin-plate spark discharge plasma generator to modify the ultrafiltration membrane and reverse osmosis membrane, and measure the decrease of membrane flux and the contact angle of the membrane surface;

[0064] 5) Use the ...

Embodiment 3

[0069] Other conditions remain unchanged, and the peak voltage of the pulse power supply in step (2) in Example 2 is changed from 15KV to 20KV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com