Production method of aluminum alloy for rail-vehicle bogie shaft box body

A bogie axle and rail vehicle technology, applied in the field of aluminum alloys, can solve the problems of poor tensile strength, yield strength, elongation, and can not meet the mechanical performance requirements of rail vehicle bogie axle boxes, and meet the mechanical performance requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014]

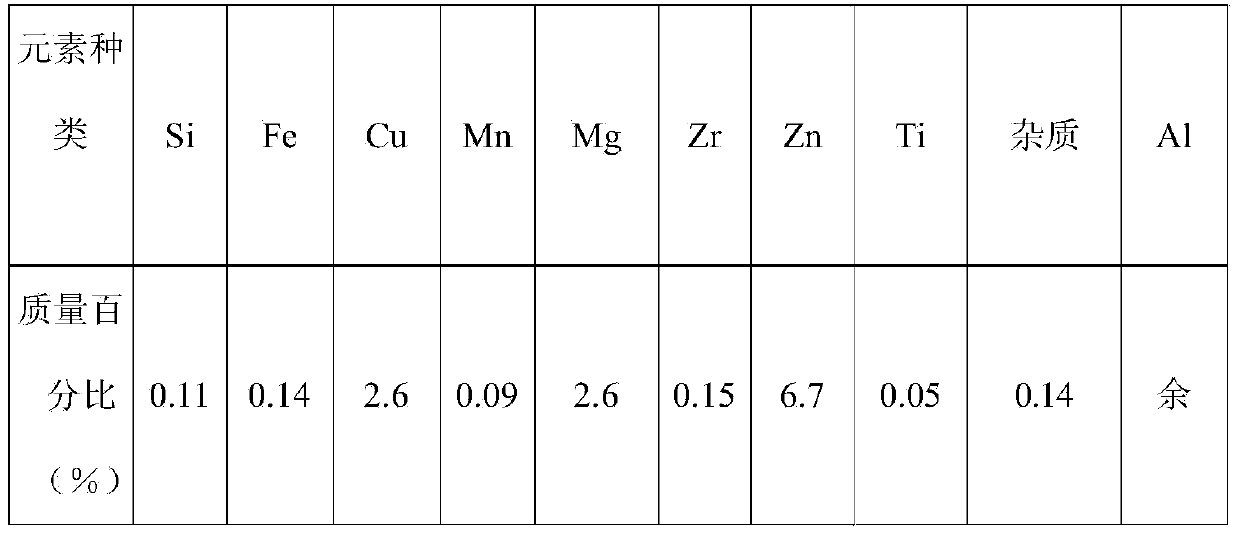

[0015] Table 1

[0016] The aluminum alloy raw material formed according to the metal mass percentage in Table 1 is melted and ingot-cast to form an aluminum alloy material. When the aluminum alloy material is processed into a bogie axle box, the tensile strength σb=506MPa parallel to its streamline direction, yield Strength σs=451MPa, elongation δ=20%, tensile strength not parallel to its streamline direction σb=486MPa, yield strength σs=433MPa, elongation δ=18%. Therefore, the axle box processed by this alloy material meets the tensile strength σb≥485MPa parallel to its streamline direction, yield strength σs≥415MPa, elongation δ≥7%, and the tensile strength not parallel to its streamline direction Strength σb≥460MPa, yield strength σs≥385MPa, elongation δ≥4% mechanical property requirements.

Embodiment 2

[0018]

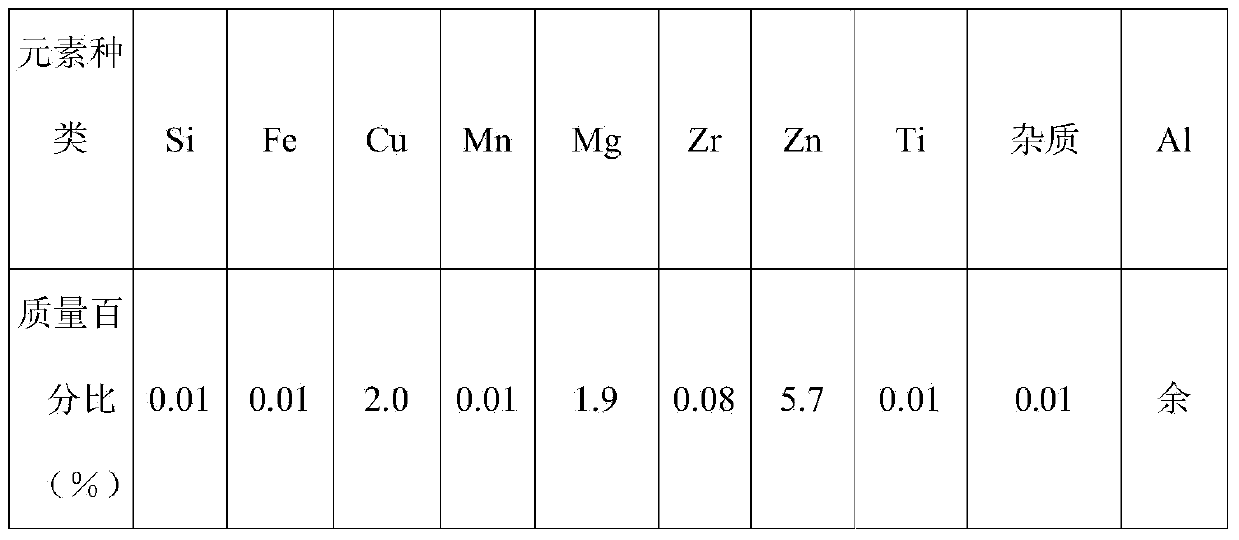

[0019] Table 2

[0020] The aluminum alloy raw material formed according to the metal mass percentage in Table 2 is melted and ingot-cast to form an aluminum alloy material. When the aluminum alloy material is processed into a bogie axle box, the tensile strength σb=511MPa parallel to its streamline direction, yield Strength σs=448MPa, elongation δ=31%, tensile strength σb=492MPa not parallel to its streamline direction, yield strength σs=420MPa, elongation δ=16%. Therefore, the axle box processed by this alloy material meets the tensile strength σb≥485MPa parallel to its streamline direction, yield strength σs≥415MPa, elongation δ≥7%, and the tensile strength not parallel to its streamline direction Strength σb≥460MPa, yield strength σs≥385MPa, elongation δ≥4% mechanical property requirements.

Embodiment 3

[0022]

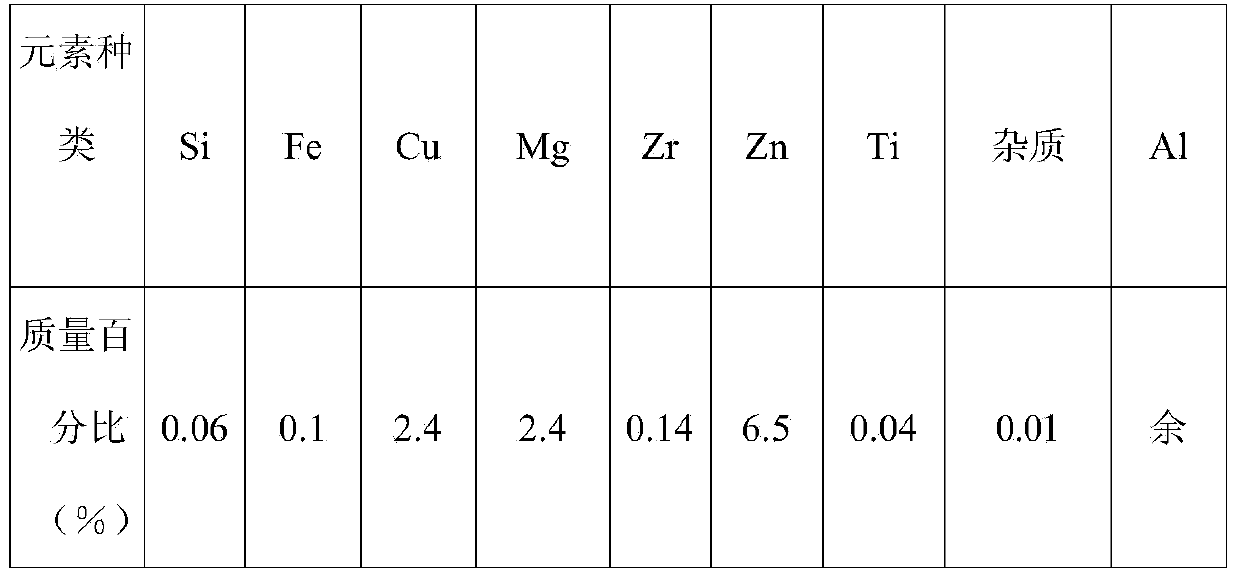

[0023] table 3

[0024] When the aluminum alloy raw material formed according to the metal mass percentage in Table 3 is melted and ingot-cast, and processed into a bogie axle box, the tensile strength σb=532MPa, yield strength σs=465MPa parallel to its streamline direction, and elongation Rate δ=42%, tensile strength σb=511MPa not parallel to its streamline direction, yield strength σs=446MPa, elongation δ=31%. Therefore, the axle box processed by this alloy material meets the tensile strength σb≥485MPa parallel to its streamline direction, yield strength σs≥415MPa, elongation δ≥7%, and the tensile strength not parallel to its streamline direction Strength σb≥460MPa, yield strength σs≥385MPa, elongation δ≥4% mechanical property requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com