Special-shaped stone point-suspension structure

A stone, point-hanging technology, applied in building construction, covering/lining, construction, etc., can solve the problems of difficult maintenance, weak control of stone strength, and low seismic performance, so as to reduce construction difficulty and solve low construction efficiency. , Improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

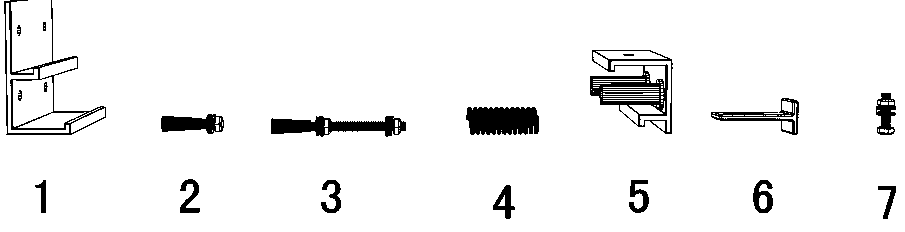

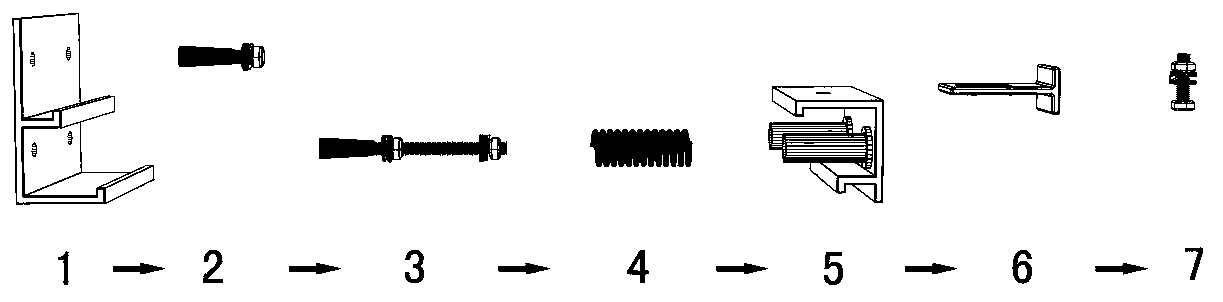

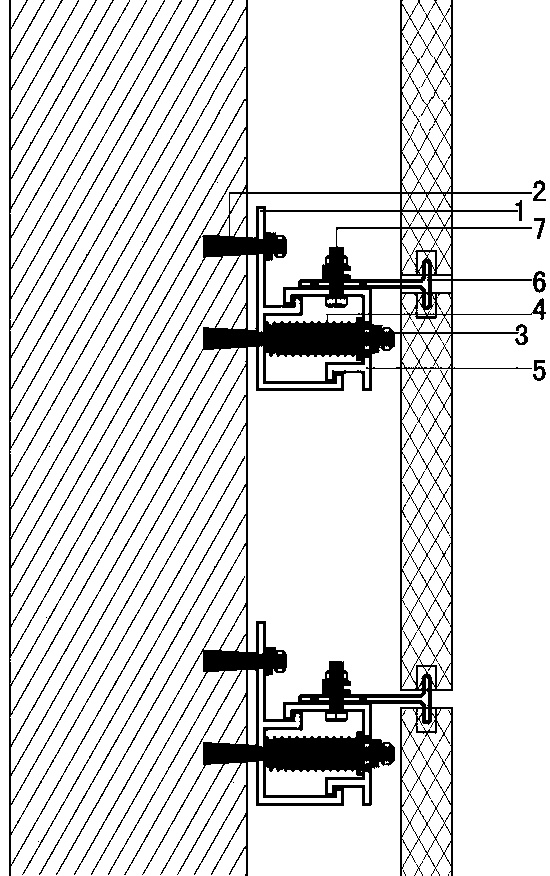

[0017] Example: such as figure 1 Shown: a special-shaped stone point hanging structure, which includes a steel part 1; expansion bolt 2; an expansion bolt 3 with an extended screw rod; a strong spring 4; steel part 2 5; corner code 6; bolt 7.

[0018] Such as figure 2 , image 3 As shown, according to the typesetting size of the wall, the basic pendants are fixed on the base from one end in order, and the flatness and curve between the stone and the base of the pendant are adjusted. Steel piece 1 is a 150mm×90mm×40mm hot-dip galvanized steel piece with a thickness of 4mm. It is an inverted F shape. There are screw holes on the upper and lower layers of the F-shaped side. Lengthened screw mandrel expansion bolt 3 is fixed with wall surface.

[0019] Steel part 2 5 is a 100mm×50mm×50mm hot-dip galvanized steel part with a thickness of 4mm. The two transverse ends are connected with corner pieces, which are connected with each other through the corner pieces, and the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com